Wholesale Heavy Racking System - Warehouse Storage Heavy Duty Steel Pallet Racking System – Woke

Wholesale Heavy Racking System - Warehouse Storage Heavy Duty Steel Pallet Racking System – Woke Detail:

Individual access to all pallets to full height of warehouse

Simple Stock rotation achieved

Easy beam adjustment accommodates variable pallet heights.

Compatible with many handling equipment styles

Conventional tolerance for floors when used to 10m high

Lower level pallets can be located on the floor.

95% High average locations utilization.

1.Product introduction of selective pallet rack

HEGERLS Selective Pallet Racking is the best solution for warehouses where it is necessary to keep a wide variety of articles in pallets. It provides direct access to all pallets for 100% accessibility and good stock rotation. Pallets can be located, accessed and moved individually providing rapid handling of palletized goods. It provides easy beam adjustment and accommodates variable pallet heights.

2.Product parameter.

|

Upright |

Box beam |

Row spacer |

Upright protector |

Side barrier |

|

80*70/90*70/100*70 |

80*50/100*50/120 *50/140*50 |

30*50/40*80 |

H300/H500 |

D76*2.5 |

3.Product feature and application

3.1 Box beam specification

3.2 Upright specification

4.Production detail of selective rack

4.1High density storage system to store pallets, efficient warehouse utilization;

4.2First-in-last-out access system;

4.3Top and back bracing are used to fix the whole racking, making the whole racking stable and safe;

4.4First level pallets can be placed on the ground floor

4.5 Flexibility and ease of installation, improve space utilization.

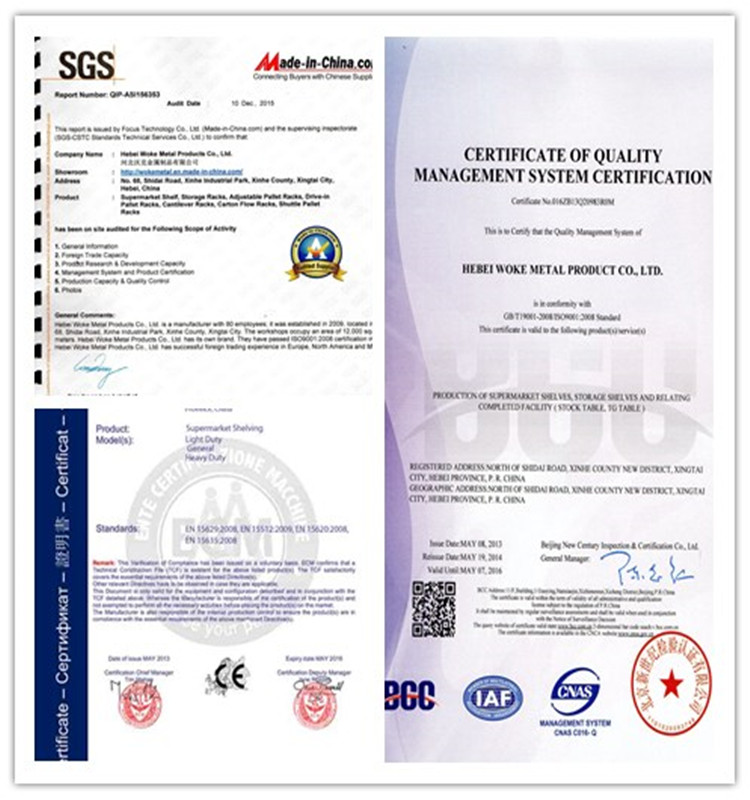

5.1 we have passed the certificate of SGS.BV,TUV and ISO quality control certificate.

Furthermore, we also have passed the certificate of environment management, health and safety management

5.2 Raw materials: cold rolled steel Q235B. or international steel standard SS400

5.3. rolling machine. We have 12 sets rolling line, could roll different size.

5.4 Power coating line. It is 500 meters long and the brand of power coating gun is GEMA, which is very famous on the coating field.

5.5 customer visiting. Our location is in hebei province, near to Beijing and Tianjin. Our airport name is Shijiazhuang zhengding international airport. Welcome your visiting any time.

5.6 exhibition. Every year we will attend canton fair and shanghai Cemat fair.

Delivery. Shipping and service

6.1 Packaged and shipping. Normally, the upright will be packed by plastic foams. And shuttle racking will be loaded into wooden pallets.

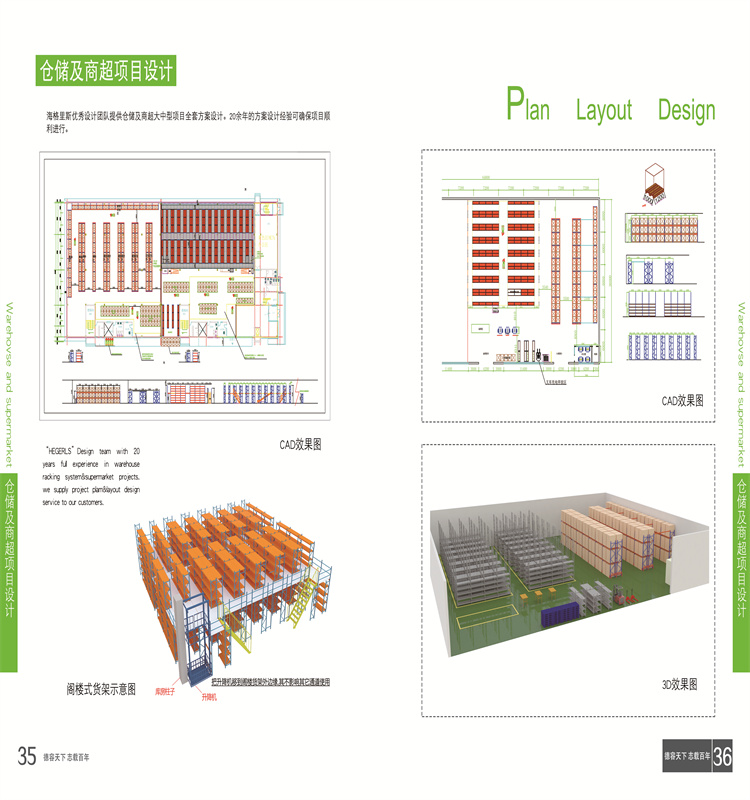

6.2 We provide layout drawing and 3d effect picture

FAQ

Q: What is the quality warranty of your products ?

A: Our quality warranty is 1 years. We will keep on providing the service out of this time and only offer cost of spare parts.

Q: What is the lead time ?

A: For the racking system, it normally take 30 days. And for the shuttle racking, it need 60 days for the production.

Q:Could you provide the layout design ?

A: Yes, we could provide the layout design freely in Autocad or 3d picture. It is our free service.

Q:What color cold be available ?

A: Normally, we have color of blue RAL5005 and orange RAL2004. The color could also be customized. Please provide us your color number.

Q:how about the installation?

A: We will provide the detailed installation drawing. For the simple traditional racking, the workers could install it according to our drawing. Or else, our engineer could go to on site to instruct the installation And buyer will afford the cost.

Latest news

The core equipment of automated warehouse-stacker

Tracked roadway stacking crane is a special crane developed with the appearance of the three-dimensional warehouse, referred to as the stacker, is a very important lifting and handling equipment in the three-dimensional warehouse, and is a symbol of the characteristics of the three-dimensional warehouse. Its main purpose is to run along the track in the roadway of the high-rise warehouse to store the goods at the entrance of the roadway into the cargo compartment; or to take out the goods in the cargo compartment and transport it to the entrance of the roadway to complete the warehousing operation.

There are many types of stacker cranes. In the current three-dimensional warehouse applications, the most common is

1. According to the structure, it is divided into single column structure and double column structure

2. According to the running track classification, it is divided into linear type and curved type

No matter what type of stacker crane is generally composed of horizontal walking mechanism, lifting mechanism, loading platform and fork mechanism, frame and electrical equipment and other basic parts. The walking motor drives the wheels to move horizontally on the lower rail through the drive shaft, the lifting motor drives the cargo platform to move vertically through the chain/wire rope/belt, and the forks on the cargo platform do telescopic movement. The walking address finder is used Control the stacker’s horizontal walking position, and raise the address finder to control the lifting position of the loading platform; through the address finder and photoelectric recognition, and the conversion of communication numbers, computer control can be realized, and automatic, semi-automatic and manual control can also be realized through the control panel .

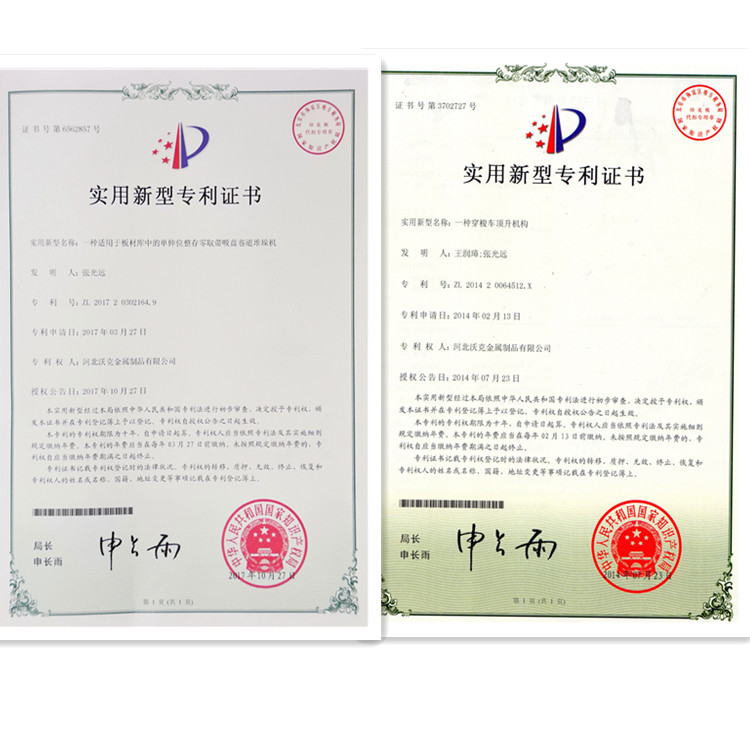

At present, in my country’s three-dimensional warehouses, stackers are widely used in industries such as machinery manufacturing, automobile manufacturing, textile industry, railways, cigarettes, and medicine. With the development of modern industrial production, the technology of tracked roadway stacker cranes is constantly improving and perfecting. Since 2017, Hegerls has obtained the new shape and new function stacker patent. It has continued to summarize experience and is committed to development and practicality. We have been very serious about building a three-dimensional warehouse for new products with safety and security!

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we'll build a prosperous future together with your esteemed organization for Wholesale Heavy Racking System - Warehouse Storage Heavy Duty Steel Pallet Racking System – Woke , The product will supply to all over the world, such as: Cyprus, Armenia, Sierra Leone, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our products have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

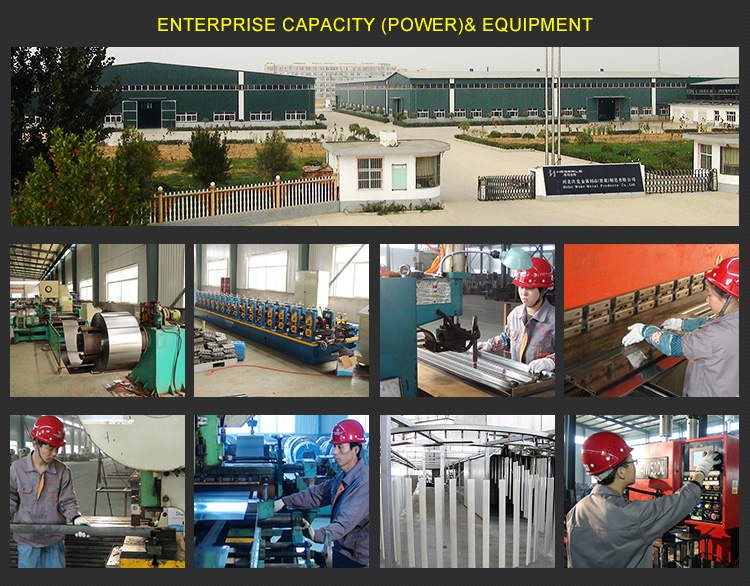

techical equipments.

Package and loading

Exhibition booth

Customer visiting

Free Layout drawing design and 3D picture

Certificate and patents

Warranty

Normally it is one year. It could also be extended.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.