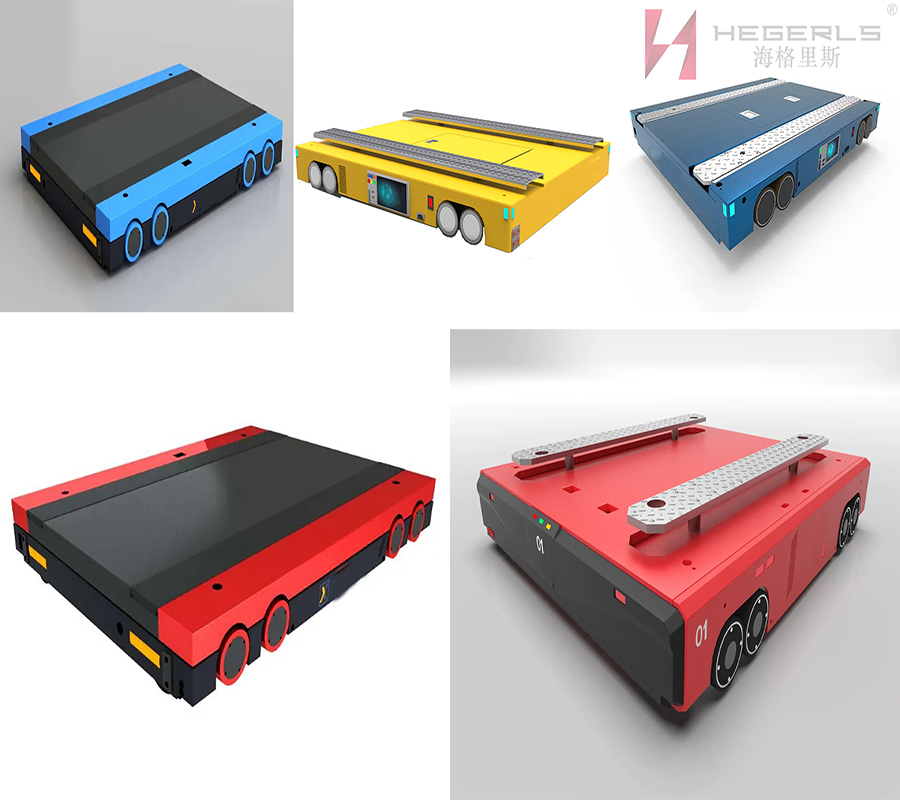

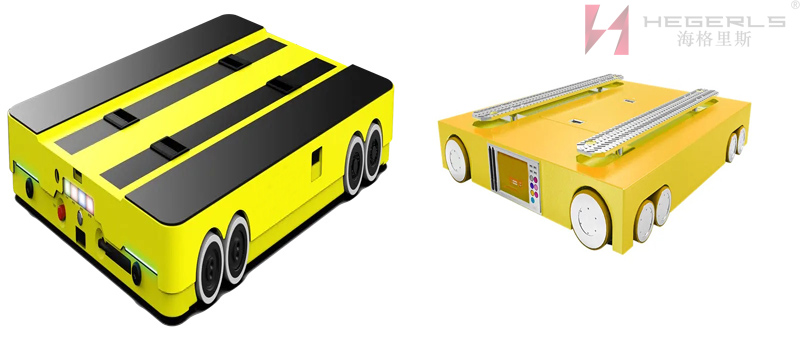

With the rapid development of modern logistics industry, four-way shuttle stereoscopic warehouse has become one of the mainstream forms of automated stereoscopic warehouse due to its advantages of efficient and intensive storage function, operating cost and systematic and intelligent management in the storage system. The intelligent four-way shuttle is a high-tech logistics handling equipment and the core part of the fully automatic unattended intelligent intensive warehouse. The Higelis four-way shuttle truck rack supply equipment can realize automatic cargo storage, automatic lane change and floor change, automatic climbing, and ground handling. It is the latest generation of intelligent handling equipment integrating automatic stacking, automatic handling, unmanned guidance and other functions.

The core functions of the Higelis four-way shuttle:

The four-way shuttle is mainly used for the automatic handling and transportation of pallet goods in the warehouse;

Automatic access to goods, automatic lane change and floor change, intelligent leveling and automatic climbing, and direct access to any location of the warehouse;

It can be driven on the rack track or on the ground without being limited by the site, road and slope, fully reflecting its automation and flexibility; It is an intelligent handling equipment integrating automatic handling, unmanned guidance, intelligent control and other functions;

Hygris four-way shuttle performance:

Upper limit of driving speed: 1.2m/s;

Upper limit of load: 2000KG;

Performance of light four-way shuttle:

Upper limit of driving speed: 1.4m/s;

Upper limit of load: 1500KG;

Energy unit: capacitance;

The application value of the Higelis four-way shuttle:

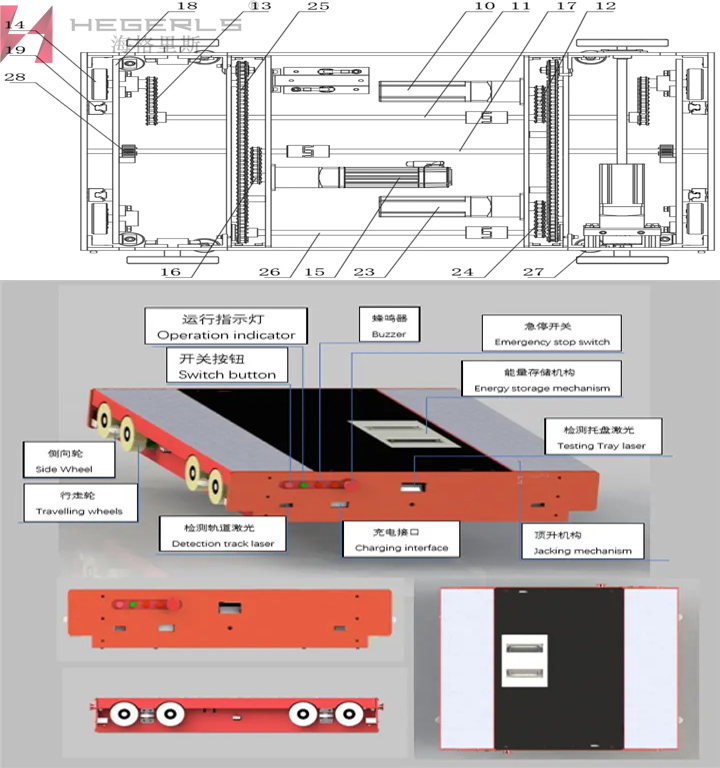

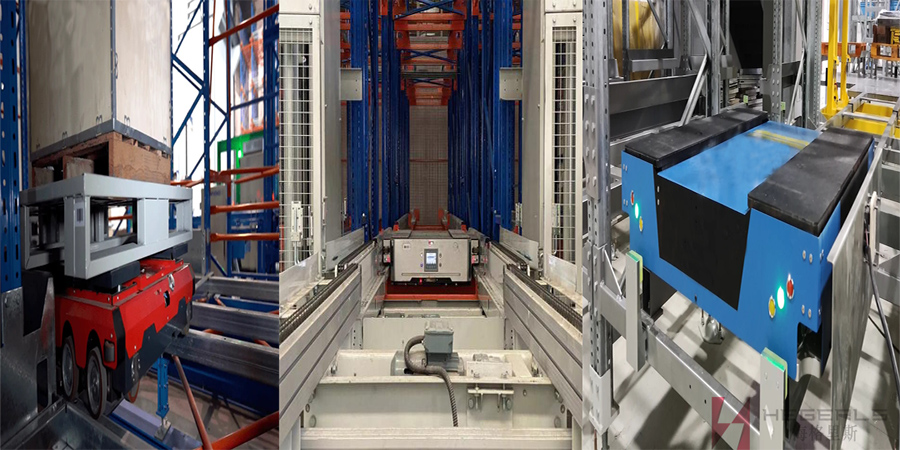

1) The four-way shuttle has compact structure: small height and size, saving more storage space; It can not only travel in four directions on the supporting rack track, but also use the vertical elevator to realize the floor changing operation, further increasing the flexibility and scalability of the warehouse rack layout and the four-way shuttle garage operation.

2) Four way travel: it can travel along the vertical or horizontal rails at will on the cross track of vertical shelves to realize one-stop point-to-point transportation and reach any cargo space on the floor of the warehouse;

3) Intelligent layer change: with the help of the Hercules elevator, the shuttle can achieve automatic and accurate layer change in an efficient way; Realize three-dimensional space movement, and accurately control the warehousing and outbound of each cargo space in the steel shelf area;

4) High utilization rate of storage space: low storage density of traditional warehouse leads to low utilization rate of total warehouse area and warehouse volume; The four-way shuttle truck runs in four directions on the main track in the shelf, and can complete the operation independently without the coordination of forklifts and other equipment. Since the volume of the main track of the shelf is smaller than the volume of the forklift operation channel, the four-way shuttle automatic intensive storage system can further improve the utilization rate of storage space compared with the ordinary shuttle truck rack system, which can generally increase by 20%~30%, 2~5 times of the ordinary flat warehouse;

5) Dynamic management of cargo space: traditional warehouses are only places for storage of goods, and storage of goods is its only function, which is a kind of “static storage”. The four-way shuttle is an advanced automatic material handling equipment, which can not only make goods automatically accessed in the warehouse according to needs, but also organically connect with production links outside the warehouse, so as to form an advanced logistics system and improve enterprise management level;

6) Unmanned automatic storage mode: it greatly reduces the workload of warehouse staff and provides the possibility of unmanned work in the warehouse. The goods leaving the warehouse are directly connected with the automatic conveyor by the tray four-way shuttle car and the vertical elevator of goods. The warehouse staff only need to monitor the operation of the system from time to time to achieve automatic storage and retrieval without the need for personnel to enter the warehouse for operation, Especially suitable for cold storage and other warehouses that are not suitable for long-term residence of personnel, it is the development direction of high-density intensive storage and automated storage in the future.

Of course, in addition to four-way vehicles and other hardware, software is also an important part of the automated warehouse. The software generally includes two systems, WMS and WCS. WCS is responsible for controlling the hardware of the entire automated warehouse as needed to achieve the normal operation of the hardware. WMS is a set of intelligent warehouse management system, which can achieve effective warehouse management, including inventory management, warehouse location management, inventory management and other comprehensive warehouse management requirements, greatly improve the efficiency of goods storage and storage and the space utilization rate of the warehouse, and can also maintain the first in first out storage of goods, eliminating the chaos or low efficiency of human factor operations.

Differences and characteristics compared with other warehouses:

1) Four way driving: You can drive along the vertical or horizontal rails on the cross rails of the vertical shelves to reach any storage space in the warehouse.

2) Intelligent climbing: It can travel intelligently on the slope track with an angle of no more than 6 degrees.

3) Automatic leveling: automatic leveling of goods is realized through displacement sensor.

4) Intelligent control: no manual operation is required to realize goods entering and leaving the warehouse.

5) The use of lithium batteries has outstanding energy-saving advantages.

6) The deadweight is one tenth of that of other handling equipment.

7) Multiple shuttle cars are linked.

8) It has both dense storage and sortability, without considering the order of entry and exit.

Hebei Walker Metal Products Co., Ltd. has been focusing on the storage shelf and storage equipment industry for many years, and has its own flagship brand HEGERLS. Hebei Walker Metal Products Co., Ltd. focuses on two professional strategic businesses with scale. One strategic business is intelligent automation system integration, intelligent warehouse, automated warehouse, automated three-dimensional warehouse, light automated shelf, automated three-dimensional shelf, heavy automated shelf, four-way car intensive automated shelf, stacker automated shelf, four-way shuttle car, shuttle board, shuttle car, AGV, robot, stacker Rotating platform conveyor line, four-way car rack, intelligent handling equipment, intelligent elevator and other strategic business modules; Two strategic businesses, namely, high-density storage shelves, storage shelves, heavy shelves, gravity shelves, pallet shelves, cantilever shelves, shuttle car shelves, drive in shelves, through shelves, press in shelves, cross beam shelves, three-dimensional warehouse shelves, cable shelves, electric mobile shelves, attic shelves, steel platforms, steel pallets, steel bins, storage cages, fluent shelves and other service areas, It also has independently developed WMS warehouse management system software. HGRIS intelligent shelves integrate resources from all over the country to establish a localized business service centered on Zhejiang covering South China, Shanghai covering East China, Jiangsu covering North China, and Hangzhou covering Central China. It is based on providing convenient, professional and localized warehousing automated three-dimensional shelf services for customers across the country. At the same time, the products and services of HGRIS cover nearly 30 provinces, cities and autonomous regions in China. The products are exported to Europe, America, the Middle East, Latin America, Southeast Asia and other countries and regions, and have made remarkable achievements overseas.

In pursuit of the optimization of each project, the best quality and perfect after-sales service, the company has successively completed the construction of large warehouses and logistics distribution centers for well-known enterprises at home and abroad, which has won the unanimous praise of many foreign enterprises and many domestic enterprise groups. Our company adheres to the corporate purpose of “being pragmatic, efficient, professional and innovative”, Adhere to the quality policy of “keeping improving, quality first, integrity and customer first”, and commit to be a professional and efficient automated warehousing and logistics equipment manufacturer!

Post time: Sep-20-2022