“Digital intelligent transformation and flexible leap” has become the development trend of warehousing and logistics technology. The current logistics industry is changing from labor-intensive to technology intensive, and the logistics system is increasingly showing an automatic, flexible, digital and intelligent development trend. Following the explosive growth of AGV/AMR market, the domestic demand for four-way shuttle cars, which are considered as “revolutionary products”, has risen rapidly in recent years, Highly concerned by the industry. It is not limited by the height of the warehouse. It can make full use of the area, set different depths according to the number of batches of materials, and invest in batches according to the efficiency requirements of different periods.

In recent years, according to the domestic and international market situation, the four-way shuttle car market is gradually warming up. Aiming at customer needs, Hebei Walker Metal Products Co., Ltd. launched an industrial high-quality intelligent tray four-way shuttle system, released a variety of innovative application scenarios of the tray four-way shuttle system, and announced that it will work with partners to create value for more enterprises.

Hebei Walker Metal Products Co., Ltd. specializes in creating high-quality products

Hebei Walker Metal Products Co., Ltd., formerly known as Guangyuan Shelf Factory, was an earlier company engaged in the shelf industry in North China. In 1998, it began to participate in the sales and installation of warehousing and logistics equipment. After more than 20 years of development, it has become a one-stop integrated service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

It also established its own brand “HEGERLS”, established production bases in Shijiazhuang and Xingtai, and sales branches in Bangkok, Thailand, Kunshan, Jiangsu and Shenyang. It has a production and research and development base of 60000 m2, 48 world advanced production lines, more than 300 people in R&D, production, sales, installation and after-sales service, including nearly 60 people with senior technicians and senior engineers. The products and services of HGRIS cover nearly 30 provinces, cities and autonomous regions in China. The products are exported to Europe, America, the Middle East, Latin America, Southeast Asia and other countries and regions, and have made remarkable achievements overseas.

Products of HEGERLS:

Storage shelf: shuttle shelf, cross beam shelf, four-way shuttle car shelf, pallet four-way shuttle car shelf, medium shelf, light shelf, pallet shelf, rotary shelf, through shelf, stereoscopic warehouse shelf, attic shelf, floor shelf, cantilever shelf, mobile shelf, fluent shelf, drive in shelf, gravity shelf, high storage shelf, press in shelf, pick out shelf Narrow aisle type shelf, heavy pallet shelf, shelf type shelf, drawer type shelf, bracket type shelf, multi-layer attic type shelf, stacking type shelf, three-dimensional high level shelf, universal angle steel shelf, corridor type shelf, mold shelf, dense cabinet, steel platform, anti-corrosion shelf, etc.

Storage equipment: steel structure platform, steel pallet, steel material box, smart fixed frame, storage cage, isolation net, elevator, hydraulic pressure, shuttle car, two-way shuttle car, parent shuttle car, four-way shuttle car, stacker, screen partition, climbing car, intelligent transportation and sorting equipment, pallet, electric forklift, container, turnover box, AGV, etc.

New intelligent robot series: Kubao robot series, which includes: carton picking robot HEGERLS A42N, lifting picking robot HEGERLS A3, double depth bin robot HEGERLS A42D, telescopic lifting bin robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42 SLAM, multi-layer bin robot HEGERLS A42, dynamic width adjusting bin robot HEGERLS A42-FW, intelligent management platform, workstation Smart Charge Point.

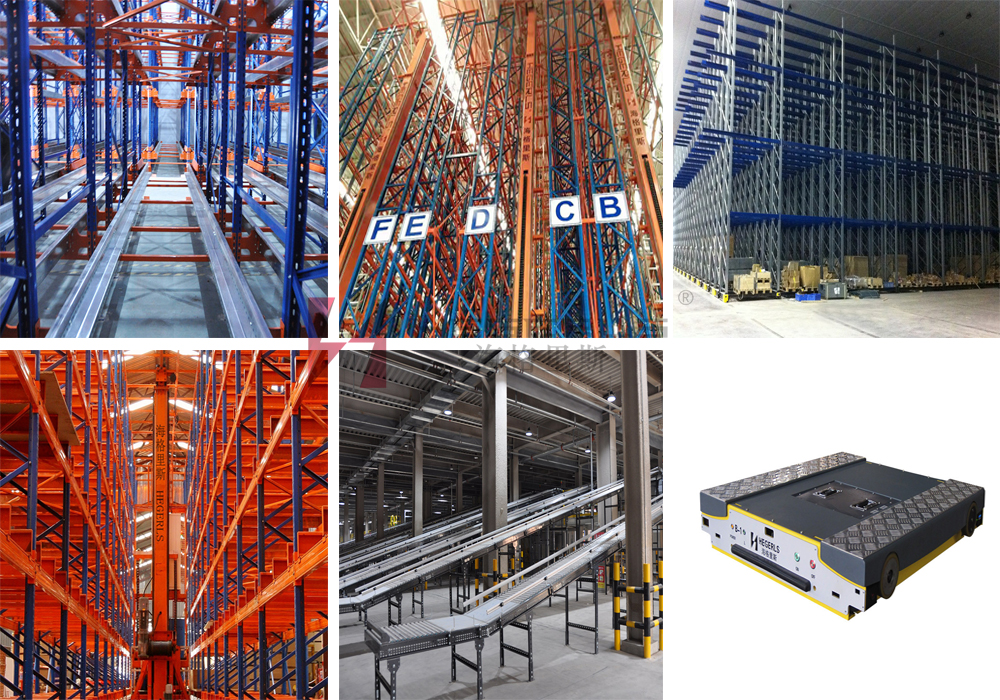

Automated stereoscopic warehouse: shuttle stereoscopic warehouse, beam stereoscopic warehouse, pallet stereoscopic warehouse, heavy shelf stereoscopic warehouse, automated warehouse stereoscopic warehouse, attic stereoscopic warehouse, layer stereoscopic warehouse, four-way shuttle car stereoscopic warehouse, mobile stereoscopic warehouse, narrow roadway stereoscopic warehouse, unit stereoscopic warehouse, through stereoscopic warehouse, cargo format stereoscopic warehouse, automated cabinet stereoscopic warehouse, strip shelf stereoscopic warehouse, picking stereoscopic warehouse, semi-automatic stereoscopic warehouse Linear guideway stereo warehouse, U-guideway stereo warehouse, traverse guideway stereo warehouse, low floor stereo warehouse, middle floor stereo warehouse, high floor stereo warehouse, integrated stereo warehouse, layered stereo warehouse, stacker stereo warehouse, circulating shelf stereo warehouse, etc.

HEGERLS pallet four-way shuttle

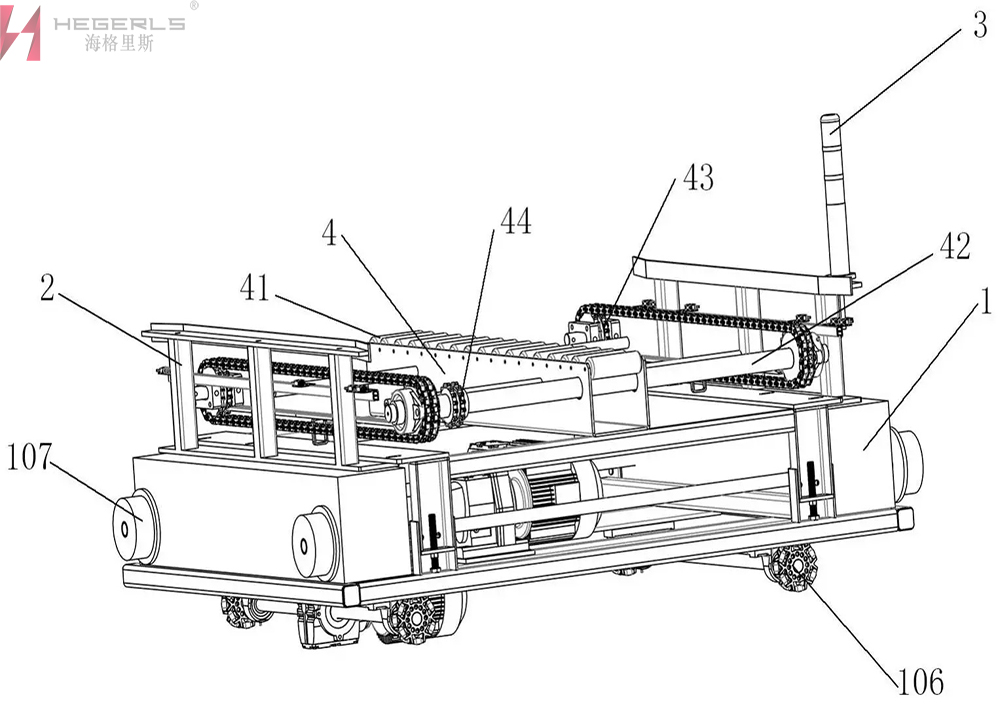

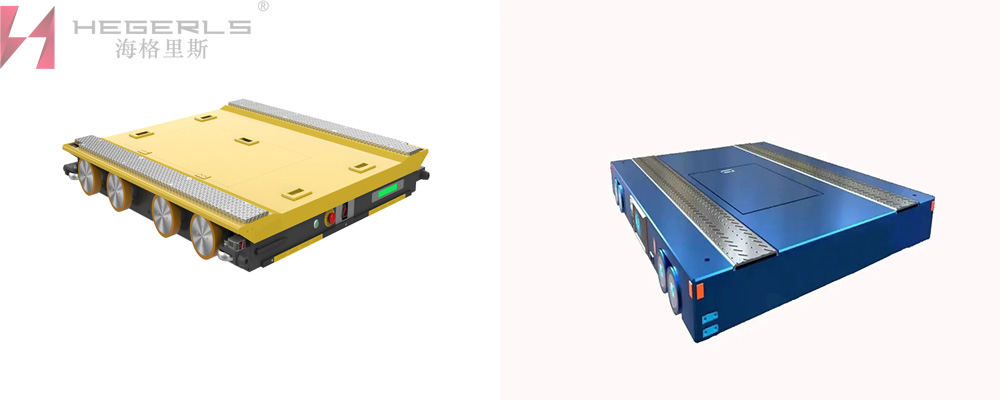

The pallet four-way shuttle car (hereinafter referred to as the “pallet four-way car”) is an intelligent device used for the handling of pallet goods. It can not only walk longitudinally but also horizontally, complete the horizontal movement and storage of goods in the shelf system, and can reach any position of the warehouse through the shelf track. The horizontal movement and access of goods in the shelf are only completed by a pallet four-way shuttle car. Through the elevator layer change, the degree of system automation is greatly improved. It is the latest generation of intelligent handling equipment for pallet intensive storage solutions. The tray four-way shuttle can realize 24-hour automatic unmanned batch pallet operation, which is not only suitable for low flow and high-density storage, but also for the core equipment of dense storage system with high flow and high-density storage. The dense shuttle shelf storage system can maximize the use of space for high-density storage, reduce costs, and improve flexibility.

HEGERLS pallet four-way shuttle safety assistance:

❑ Sensor design, pallet can be accurately detected for handling;

❑ Laser limit technology to ensure the safety of shuttle trucks and goods;

❑ The track is locked, and the shuttle only runs on the track, which is safe and reliable;

❑ Tray anti-skid design;

❑ Laser ranging, early warning, multi-level speed and position control;

❑ Dynamic position detection and real-time traffic safety assurance.

HEGERLS pallet four-way shuttle features:

❑ Non hydraulic innovative reversing and lifting mechanism;

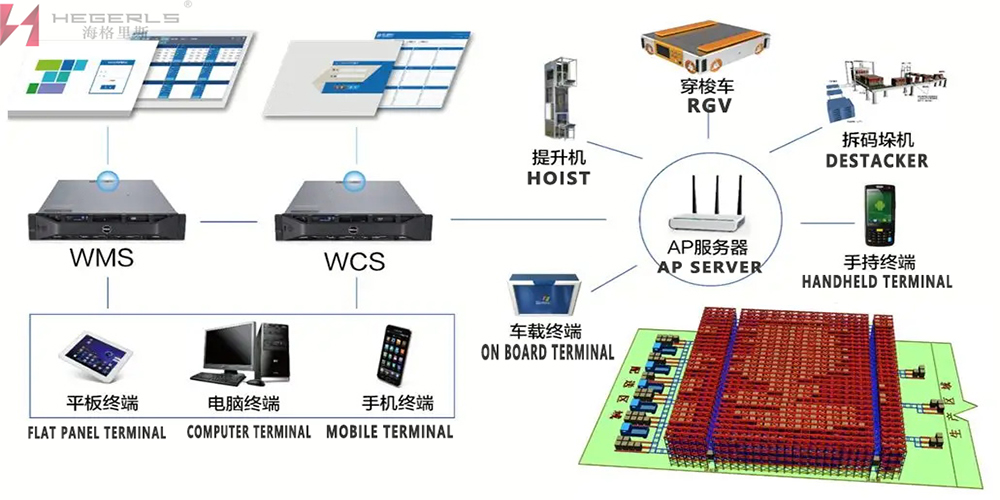

❑ The self-developed third-generation integrated circuit control system ECS fully integrates the energy module, control module, communication module and data acquisition module;

❑ Support the operation of multiple vehicles on the same floor, and have the ability of self detection and self obstacle avoidance;

❑ Support mixed placement of multiple pallet sizes;

❑ Support operation and maintenance data acquisition and analysis;

❑ Four way driving, cross roadway and cross layer operation;

❑ Location awareness, assisting WCS in intelligent scheduling and path control;

❑ Flexible, flexible and expandable.

HEGERLS Pallet Four way Shuttle Storage System Value

1) The pallet four-way shuttle car stereo warehouse has low requirements for warehouse height, area and irregularity

For the traditional stacker warehouse, the bottom and top of the shelf need to reserve enough space because of the stacker picking up, which is very wasteful for the low warehouse. In addition, when there are many columns in the vertical warehouse of the stacker and they cannot be arranged in the middle of the shelf, the stacker can only give up the whole space, while the pallet four-way shuttle only needs to avoid the space of the columns. For the tray automation of small cold storage, it is difficult to have other automation schemes except for the tray four-way shuttle car scheme.

2) Increase the number of shuttle buses according to different efficiency requirements

When a traditional stacker stereo warehouse is completed, it is impossible to add more stackers, and the highest efficiency is locked. However, the three-dimensional warehouse of the tray four-way shuttle car is different. It can purchase several when the efficiency requirements are not high in the early stage, and purchase several more when the warehouse is added. It can be used only after the system is set up. It is a plug and play type. The tray four-way vehicle storage system has many advantages, especially in the buildings with more irregular columns. Of course, as a dense warehouse, the more the number of storage trays in a single SKU, the fewer the lanes, and the higher the space utilization.

3) Flexible design of storage space depth according to the storage capacity of product SKU

The traditional stacker can only stand at single depth or double depth, and the roadway space takes up more; The pallet four-way shuttle can move the warehouse freely to improve the space utilization. At the same time, the pallet four-way shuttle can store multiple SKU products within the depth of a single roadway to maximize the storage space.

Comparison between HEGERLS pallet four-way shuttle and traditional pallet

Compared with the traditional tray automation solutions, the tray four-way vehicle system has the advantages of high flexibility, strong site adaptability, energy conservation and environmental protection, and large capacity improvement space. Although the shuttle technology was originally developed in Europe, the Chinese market has rich application scenarios. Hebei Walker Metal Products Co., Ltd. is a pallet four-way shuttle under its own brand HEGERLS. In terms of trolley structure design and intelligent scheduling software, Hebei Walker Metal Products Co., Ltd. has achieved curve overtaking, which is now the first echelon at home and abroad.

Post time: Nov-11-2022