With the rapid development of high-tech, the warehousing and logistics industry has gradually moved towards unmanned, automated, intelligent, and intensive directions, and the demand for users has also been increasing day by day. Among numerous warehousing and logistics equipment, four-way shuttle buses are increasingly favored and put into use by major small and medium-sized enterprises. The four-way shuttle not only has good scalability and adaptability, flexible picking, but also features fast deployment, safety and reliability, and high-density storage.

The four-way shuttle is divided into box type shuttle and tray type shuttle according to the different types of units it processes. In the high standard warehouse field, which is a key focus of intelligent storage equipment enterprises, HEGERLS, with its four-way shuttle system for material boxes, has a first mover advantage in the three-dimensional warehouse of material boxes up to 50KG. It not only maintains a stable position in the domestic market, but also sells overseas; At the same time, HEGERLS has also launched stacker crane storage equipment and a tray type four-way shuttle system with rapidly growing demand, which is used to solve the dense storage and retrieval of tray elevated three-dimensional warehouses weighing over 100KG.

Working principle of the four-way shuttle car for the material box

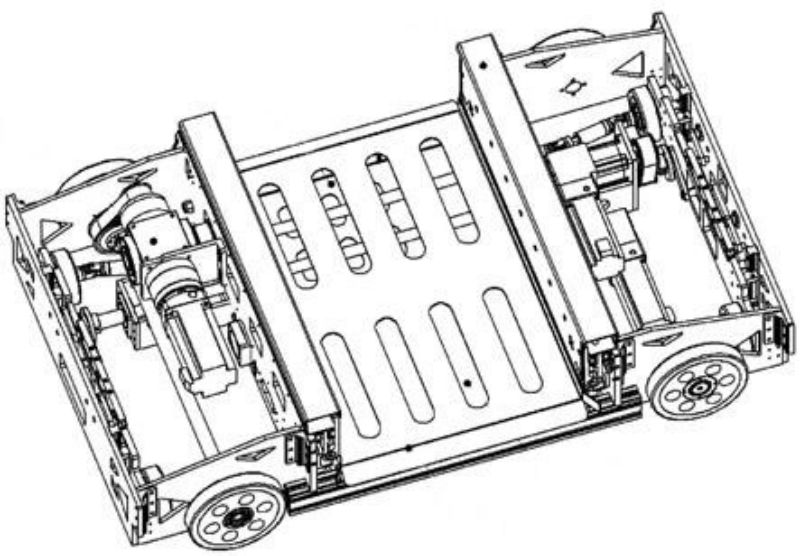

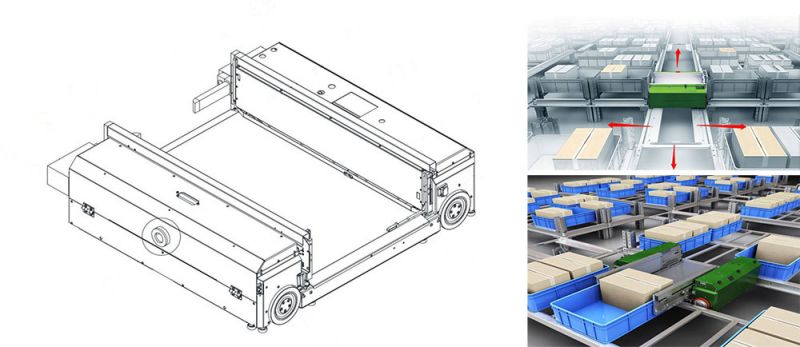

The material box type four-way shuttle is an intelligent transportation equipment that walks on the shelf track and is used to achieve the inbound and outbound operations of material boxes or cardboard boxes; Using a precision retractable finger gripper, the material box is taken out and transported to the designated exit position. At the same time, the material box at the entrance position can be stored in the designated storage space.

The development of the bin type four-way shuttle system was initially mainly aimed at the development of a "cargo to person" sorting system, suitable for situations with multiple changes and sorting varieties. However, with the increasing demand for logistics automation and the increase in the number of automated bins. The demand for the material box four-way shuttle system in the market is gradually increasing, which makes the advantages of the Hegerls four-way shuttle in storage efficiency and storage space utilization more prominent, and its application scenarios are constantly expanding.

The HEGERLS container four-way shuttle is a more flexible product, with a structure and control method similar to that of a pallet four-way shuttle. It can carry tens of kilograms of container cargo and has universal adaptability, which can be applied to various warehouse types or flexibly match actual needs by increasing or decreasing the number of carts; Especially in the cargo to person picking system, due to the fact that the small car can change layers through the elevator, it can operate flexibly in three-dimensional space. In this system, the shuttle car can travel in multiple directions without being limited by space, and can achieve efficient and flexible operations across tunnels and floors. During the overall system operation, it is possible to reduce the dependency of single machine products on the system, allowing multiple processes to work in parallel. When there is a change in order demand, the system can flexibly mobilize vehicles from adjacent layers and tunnels to concentrate work. Suitable for scenarios with large SKUs and high efficiency in inbound and outbound requirements, such as the storage and picking process in industries such as e-commerce and medical, and can be flexibly paired with multiple solutions.

The HEGERLS box type four-way shuttle car adopts an encoder+laser sensor method, which can provide real-time feedback on the position of the vehicle body, with a positioning accuracy of ± 2mm. If it exceeds the range, the shuttle car will enter an alarm state. In addition, the vehicle body is equipped with emergency stop and power-off brake protection functions. In terms of path planning, the system adopts the S-curve algorithm. Based on the destination location, the shuttle can automatically plan the acceleration distance, uniform speed distance, and deceleration distance to reach the target location at a faster speed and in a shorter time. On the box type hoist used for shuttle cars, the Hegerls also incorporates lifting barcode positioning. Through built-in encoders and external detection positioning functions, it can achieve material safety protection and improve operational smoothness, thereby improving efficiency.

Hebei Woke Metal Products Co., Ltd. is a well-established enterprise specializing in four-way shuttle cars, elevators, dense warehouses, shuttle shelves, and more, both domestically and internationally. The company mainly operates new energy three-dimensional warehouses, four-way shuttle vehicle three-dimensional warehouses, multi-layer shuttle vehicle three-dimensional warehouses, parent-child shuttle vehicle three-dimensional warehouses, cold storage shuttle vehicle three-dimensional warehouses, rack integrated three-dimensional warehouses, aluminum profile three-dimensional warehouses, stacker crane three-dimensional warehouses, automated three-dimensional warehouses, three-dimensional warehouse shelves, stackers, elevators, conveyor lines, palletizing machines, transfer machines, RGV, AGV, WMS (warehouse management system), WCS (Equipment Control Software), Intelligent Control System, Steel Structure Platform, Attic Shelves, Beam Shelves, Shuttle Shelves, Entry Shelves, Narrow Lane Shelves, Double Depth Shelves, Cantilever Shelves, Mobile Shelves, Heavy Storage Shelves, Medium Shelves, Three dimensional Warehouse Steel Trays, Storage Cages, WCS Management System, WMS Management System, etc.

After entering the international market in 2011, Hagrid exported supermarket equipment, warehousing equipment, and related supporting products to countries and regions such as North America, South America, Europe, Southeast Asia, and Africa. In recent years, the company has increased its research and development efforts in automated warehousing equipment, and has won national patents for two types of automated warehousing equipment: intelligent shuttle cars and intelligent sheet metal warehouse stackers. Up to now, Hebei Woke has implemented numerous logistics projects, with cases widely applied in various industries such as medical, e-commerce, 3C, footwear, retail, books, automobiles, manufacturing, new energy, machinery, chemical, etc. Since its establishment, Hebei Woke has developed rapidly and gained numerous accolades. It has always focused on the field of warehousing and logistics, providing intelligent solutions based on hardware, driven by data, and centered on systems, helping enterprises transform and upgrade to "intelligent manufacturing" and achieve new breakthroughs in enterprise development. We rely on high-quality technical personnel and sales teams, adhering to the principles of honest operation and understanding customer needs. Through good reputation and thoughtful pre-sales and after-sales services, our company has won the trust and support of users. The company will continuously research and develop products that meet market and customer needs according to the requirements of different customers.

Post time: Nov-30-2023