In recent years, with the rapid development of China’s economy and the increasingly close outreach, logistics research has been highly valued by many circles. Advanced manufacturing mode, diversified market demand, shortening of product life cycle, rapid response of supply chain, globalization of manufacturing and other characteristics make logistics activities more extensive and frequent in time and space. At the same time, the logistics service industry is also booming, and a large number of specialized logistics centers and logistics enterprises have been born. E-commerce has had a great impact on the traditional logistics business. In this environment, logistics activities, including goods transfer and distribution, are required to respond faster and faster, with shorter lead time and more turnover times.

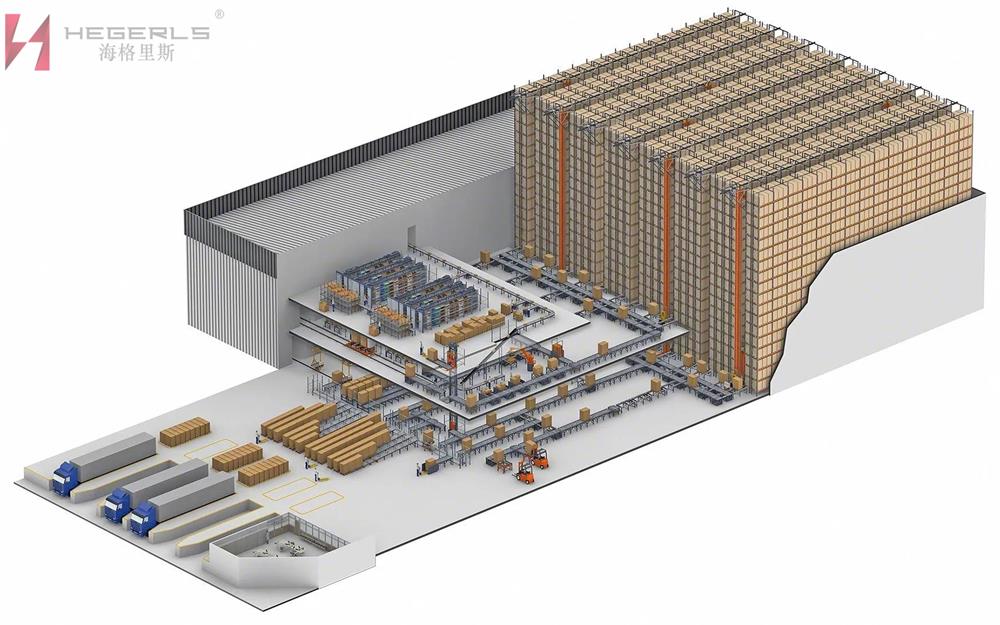

Subsequently, automated three-dimensional warehouse has gradually emerged, and the automated three-dimensional warehouse has become a high-tech intensive electromechanical integrated warehouse integrating information, storage and management, and the fields involved are also quite extensive. The management and control of automated three-dimensional warehouse involves many factors and aspects. The scheduling of transportation equipment, i.e. the scheduling of warehouse in and out, is related to the economic and social benefits of the warehouse.

Not only that, automated three-dimensional warehouse is also an important part of the social logistics system, but also a complex integrated automation system. As one of the main functions of logistics, warehousing will realize the transfer of goods in time and create time benefits. Automated three-dimensional warehouses have incomparable advantages over traditional warehouses in this regard. Automated three-dimensional warehouse has received great attention since its birth, and the research on its related technology and management has never stopped. In modern society, with the revolutionary change of production mode and technology, automated three-dimensional warehouse has become an important factor to support enterprises and social economic activities. Its economic and social benefits are gradually accepted. Automated three-dimensional warehouse has also become the focus of capital and technology investment of enterprises and society.

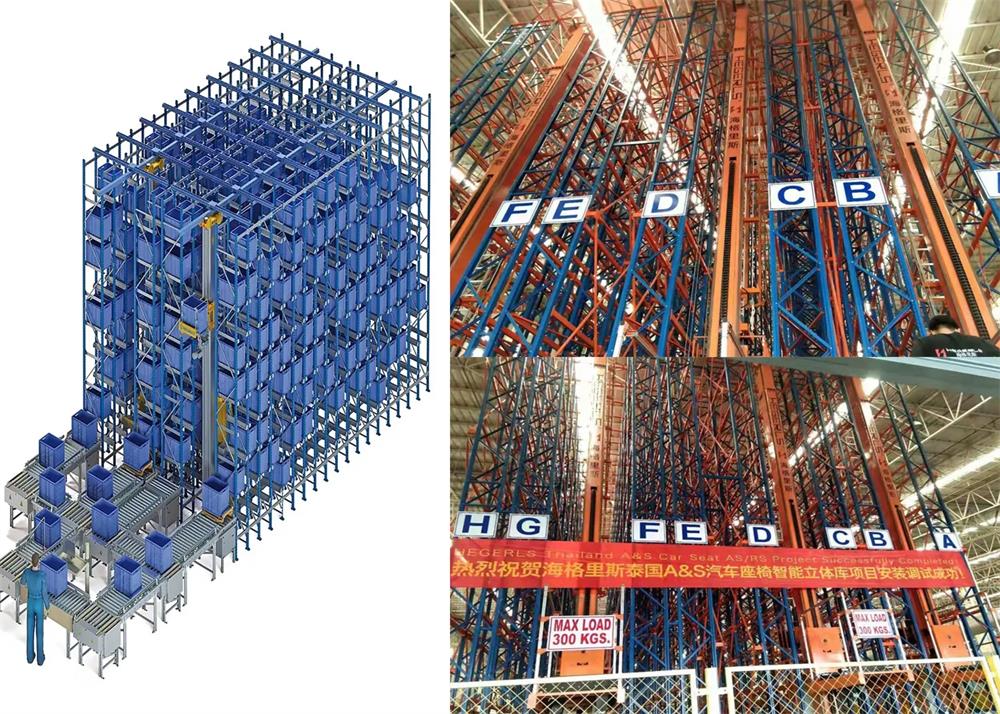

Automated three-dimensional warehouse is also called high-rise shelf warehouse and automatic access system. As/rs (automated storage and retrieval system) is a system that automatically stores and takes out materials without manual processing. This concept covers a wide variety of systems with different complexity and specifications. The system as/rs refers to such a system, which uses several, dozens or even dozens of high-rise shelves, transporters that can store and take out goods at any cargo location in the roadway, and computer-controlled communication systems. The system can also be directly connected with other production systems to connect production and demand.

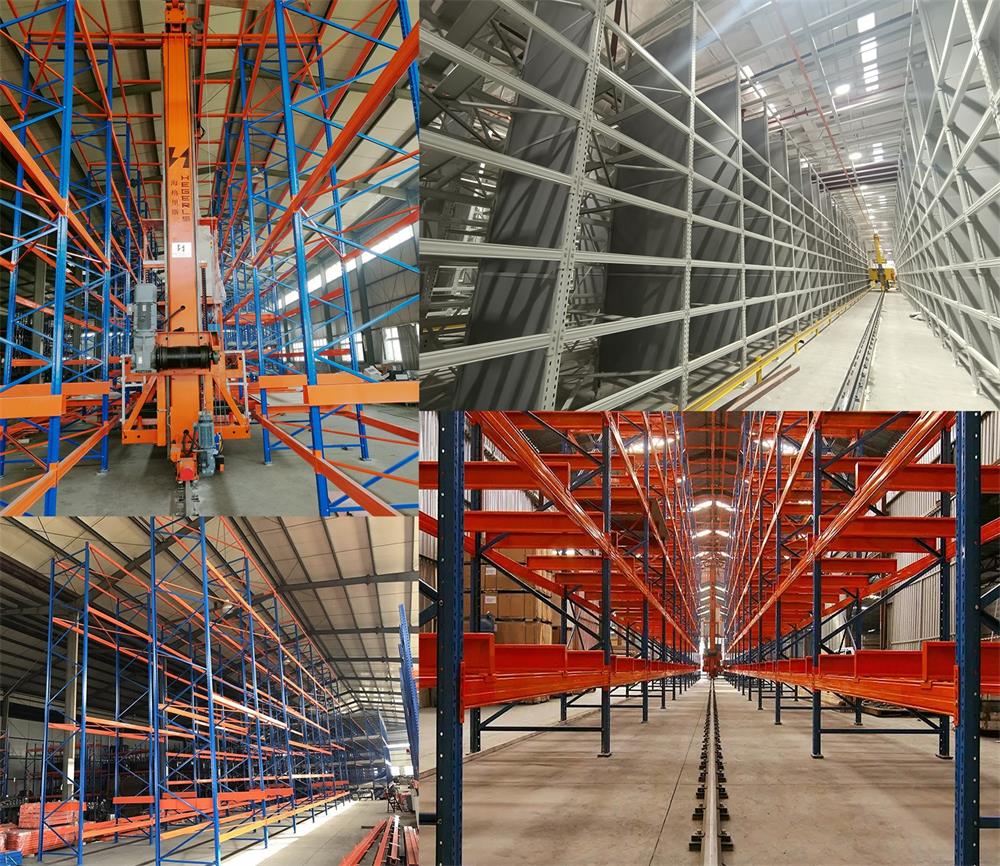

With the emergence and use of automated three-dimensional warehouse, its storage providers also appear. Among many storage industry fields in Hebei, hegerls storage shelf manufacturer is one of them, and has served in the storage industry for more than 20 years. It not only produces three-dimensional storage shelves, but also produces and manufactures pallet racks, drive in racks, flow racks, flow racks, mobile racks The cantilever rack, attic shelves, laminated shelf, steel platform and other storage shelves with high management and efficiency; Hercules Hergels storage shelf manufacturer also produces storage equipment for storage shelves, such as forklift, tray, elevator, stacker, storage cage, container, RGV, four-way vehicle, child and mother car Intelligent conveying and sorting equipment, kubao robot and other high-tech storage equipment. At the same time, these storage shelves and storage equipment have been sold at home and abroad, and have been put into use in major enterprises for a long time, which has also been well evaluated and favored by major enterprises.

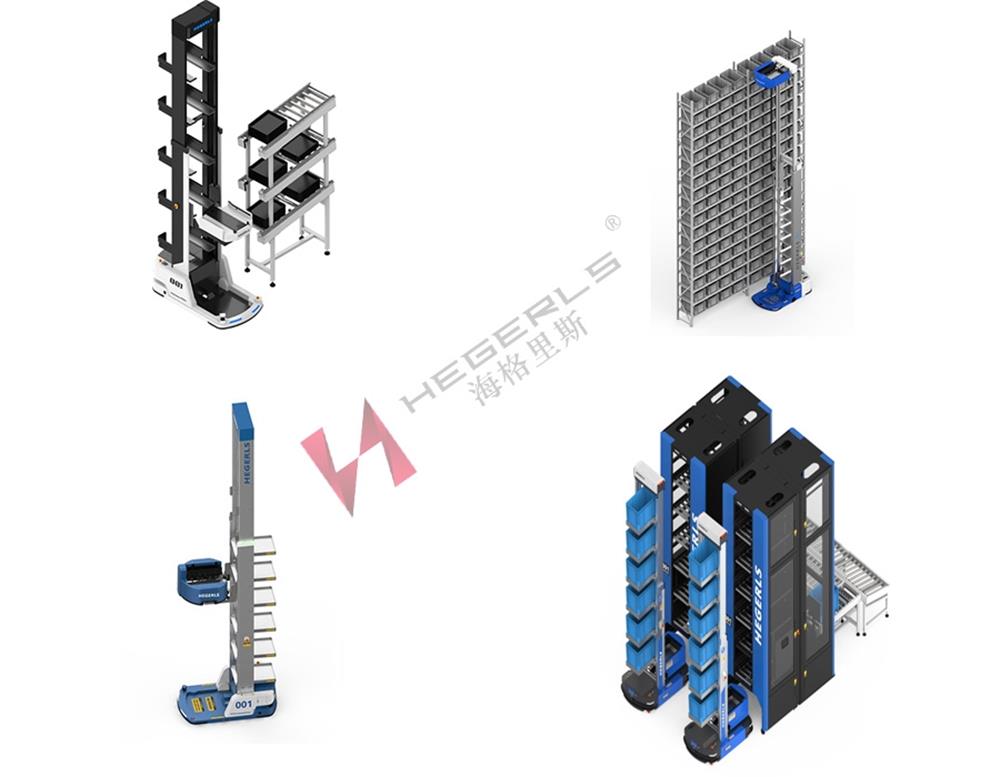

Here, one more thing to say is the new product of hegerls – kubao robot

Kubao robot is a new high-tech storage product with the functions of intelligent picking and handling, autonomous navigation, active obstacle avoidance and automatic charging. It has the characteristics of high stability and high-precision operation. It can replace the repeated, time-consuming and heavy manual access and handling work, achieve efficient and intelligent “goods to people” picking, and greatly improve the storage density and manual efficiency of the warehouse.

Features and advantages of hegerls kubao robot

• intelligent picking and handling

Autonomous picking, intelligent handling, autonomous navigation, autonomous charging, high positioning accuracy

• wide storage coverage

The storage range covers 0.25m to 8m solid space

• high speed stable movement

Full load and no-load speed up to 1.8m/s

• multi container handling

Each robot can access up to 8 containers at one time

• wireless network communication

Support 5GHz band Wi Fi roaming to ensure barrier free operation

• multiple safety protection

It has many safety functions, such as obstacle detection, active obstacle avoidance, anti-collision, alarm and emergency stop

• multiple model choices

Some models are compatible with cartons / bins and multi size containers

• flexible product customization

Support customized requirements such as fuselage height and color

• optimal solution

Tailor the best solution according to different application scenarios

Post time: Jun-20-2022