Human computer interaction multi-function workstation, a conveyor line workstation with a warehousing efficiency of up to 300 boxes / hour

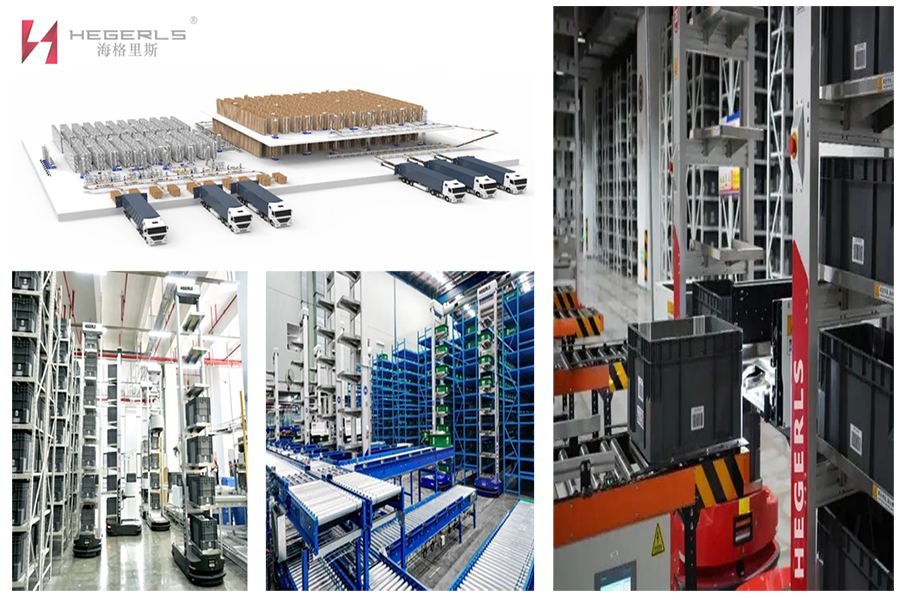

According to the current market, different enterprises in different industries have a sharp increase in interest in high-density warehousing solutions, which is also because society has seen the benefits of automation. In this regard, Hercules’ innovative ACR (box storage robot) solution can meet the needs of major enterprises for high return on investment. At the same time, it is effective in improving the storage density of warehouses, reducing the labor intensity of workers, and improving productivity. At the same time, Hergels storage shelf provider has also officially seen this aspect. After layers of investigation and exploration, our leaders and Hercules innovation have become partners and jointly provide storage solutions for major enterprises such as third-party logistics companies.

About hagerls warehousing service provider

Hegels Hegels is an independent brand established by Hebei Walker metal products Co., Ltd., with headquarters in Shijiazhuang and Xingtai production bases, and sales branches in Bangkok, Thailand, Kunshan, Jiangsu and Shenyang. It has a production and R & D base of 60000 square meters, 48 world advanced production lines, and more than 300 people in R & D, production, sales, installation and after-sales, including nearly 60 people with senior technician and senior engineer titles. Hagris’ products and services cover nearly 30 provinces and autonomous regions in China. Its products are exported to Europe, America, the Middle East, Latin America, Southeast Asia and other countries and regions, and have made remarkable achievements overseas. In recent years, haggis has completed a series of warehousing and logistics projects for well-known enterprises such as Sinopec, PetroChina, Coca Cola, YIHAI KERRY, Alibaba Cainiao logistics, JUNLEBAO, jinmailang, North China pharmaceutical, Lucky Film, Yuantong express, Inner Mongolia Xinhua Publishing and distribution group. He has successively designed, developed, produced and processed warehousing and logistics products and related supporting facilities for Alibaba Cainiao logistics Jiangmen large turnover center project, Shanxi automobile transportation group “smart cloud warehouse” large series warehousing and logistics project, beiren Group Logistics Park project, Guoda Group Logistics Center, YIHAI KERRY (Nanchang, Xi’an) logistics reserve project, Yuantong Express warehouse 9 series warehousing and logistics project.

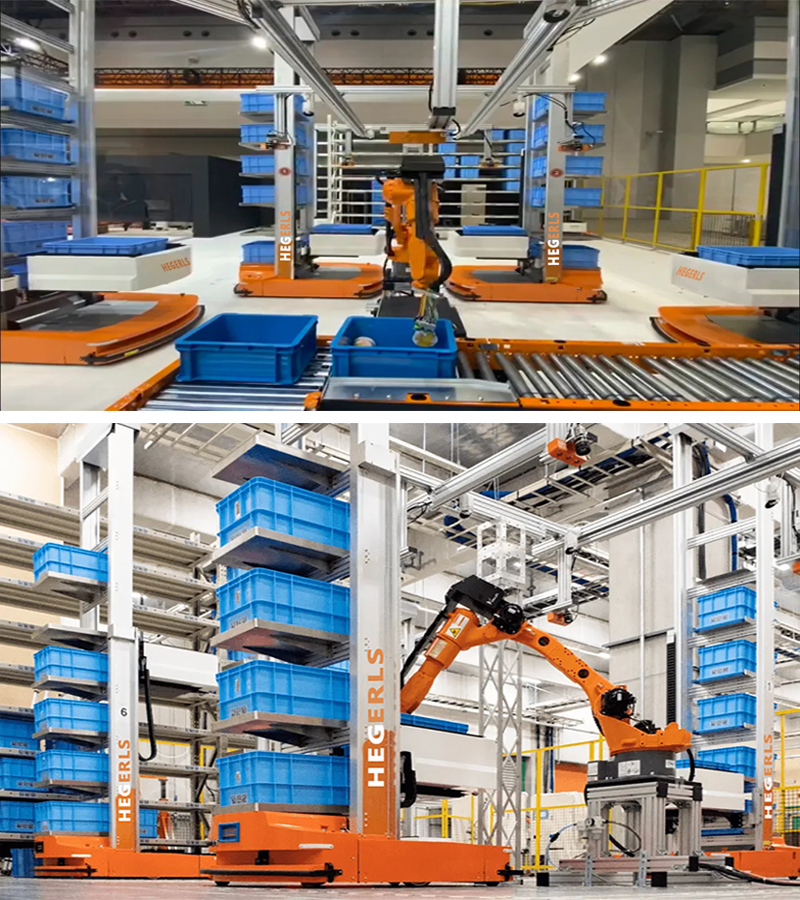

For Hergels warehousing service providers, the primary task to be considered at present is to continue to deepen the field of warehousing automation, increase research and development efforts, constantly Polish higher quality and perfect industrial solutions, and provide driving force for the intelligent transformation of global logistics. Therefore, they have reached an agreement and cooperation with Hergels innovation, and introduced their ACR (box type warehousing robot) and a series of related intelligent software and warehousing equipment and facilities. With the advantages of intelligence, flexibility and efficiency, ACR system can adapt to the storage and logistics needs of different enterprises. At the same time, ACR can connect with the attribute of the transmission line and expand more accessible business scenarios. Now, we will explore the conveyor line workstation in the multi-function workstation that can be matched with ACR together with Hergels storage service provider.

Hagerls – conveyor line workstation

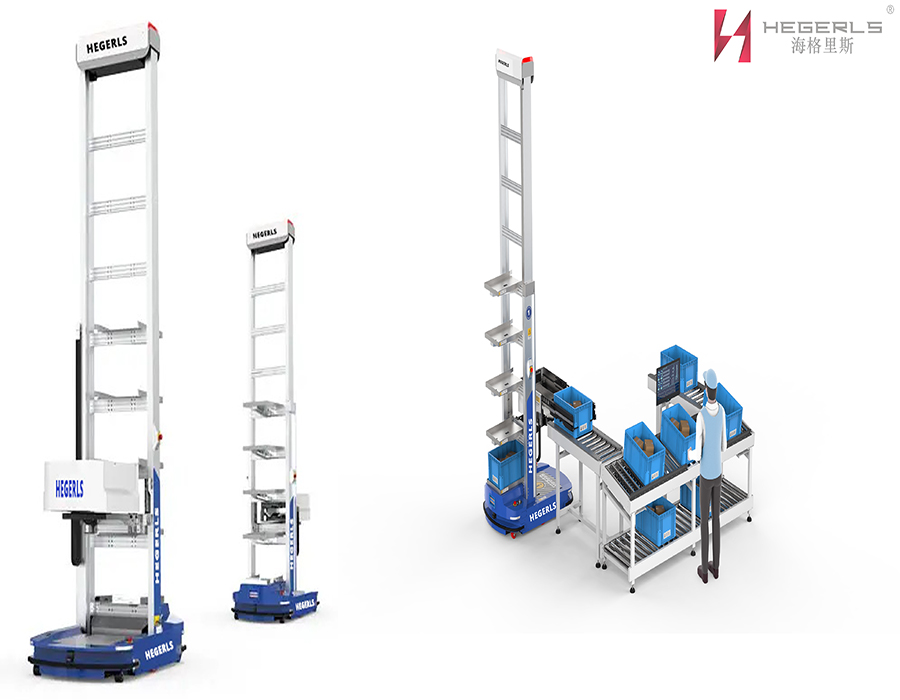

The conveying line workstation is composed of conveying line, visual Kanban, shelf and light sorting system. It is connected with kubao series robots to automatically convey the material boxes unloaded by the robots or the material boxes that need to be loaded, so as to realize a more automatic warehousing and warehousing function. The workstation conforms to the ergonomic design, and the workers are indirectly connected with the robot. It can complete the goods picking on the conveying line without too much movement. It has the advantages of humanization, convenient operation, efficient warehousing, etc. Applicable scenarios: applicable to all scenarios, as well as the temporary expansion of equipment in the peak period of e-commerce and footwear industry.

Hagerls – functions of transmission line workstation:

Intelligent sorting – configure visual Kanban to guide workers to sort goods;

Convenient operation – workers can complete goods picking on the conveying line without walking and moving;

Safety and comfort – Ergonomic design, workers choose safety and comfort;

Reduce waiting – there is a buffer between manual picking and robot operation to reduce robot waiting time;

Efficient warehousing and egress – the efficiency of each robot can reach 25-30 boxes / hour + 25-30 boxes / hour, and the warehousing and egress efficiency of a single workstation can reach up to 300 boxes / hour.

Hagerls – the role of conveyor line workstation

Research and development of logistics warehousing robot, focusing on the research and development design and scheme planning of box warehousing robot system. Its container to person system includes kubao robot, software system haiq and workstation, which can realize material picking, handling and sorting, serve logistics warehouses and factories with flexible automation transformation needs, meet customization needs, and apply to a variety of application scenarios. The combined application of the conveying line workstation and kubao robot can enable customers to realize the automatic transformation of the warehouse within a week, improve the storage density by 80%, and improve the work efficiency of workers by 3-4 times.

Hagerls – solution for transmission line workstation

The material box is shared through the serial workstation of the circular conveyor line, so as to realize the minimum handling times; The man-machine friendly conveyor line sorting is combined with the light seeding wall to achieve the fastest sorting speed. Robots and loaders support flexible docking with the conveyor line, with high integration. With such a solution, we can achieve a robot box moving efficiency of 40 + boxes / hour, an automatic loading and unloading machine loading and unloading speed of 600 + boxes / hour, and a manual picking efficiency of 300-400 lines / hour, and successfully achieve the customer’s 5W lines / day production capacity goal. The system supports automatic identification of bin posture, improves picking accuracy and efficiency through the picking display interface and electronic labels, and designs different picking schemes for different orders to maximize operation efficiency.

Robotics and warehousing automation not only mean the progress of the logistics industry, but also indicate that warehousing and logistics will be closer and closer to the life of ordinary people. In the future, hagerls warehousing service providers will work with more enterprises in need to explore more efficient intelligent logistics innovative solutions, help major enterprises in major industries to realize the transformation and upgrading of warehousing automation, and contribute more to the warehousing industry.

Post time: Jul-13-2022