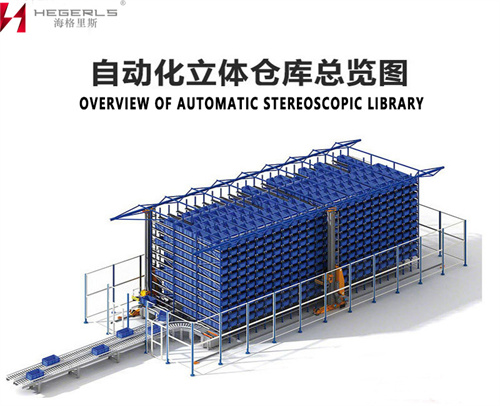

With the rapid development and integration of science and technology and logistics, automated three-dimensional warehouse has become the main storage choice of many enterprises. The automatic three-dimensional warehouse is a multi-layer elevated warehouse system used for storing goods. It is composed of three-dimensional shelves, stackers, conveyors, handling equipment, pallets, management information systems and other peripheral equipment. It can automatically complete the storage of goods according to instructions, and can automatically manage the inventory location. It has played a major role in modern enterprises. The automatic three-dimensional warehouse is widely used in the production logistics and distribution logistics of electronics, machinery, medicine, cosmetics, tobacco, automobile and other industries. It can improve the logistics management level, improve the operation efficiency, reduce the damage and difference of goods, save land, and save human, material and financial resources.

Structure composition of automatic three-dimensional library

*Shelf: steel structure used to store goods, mainly including welded shelf and combined shelf.

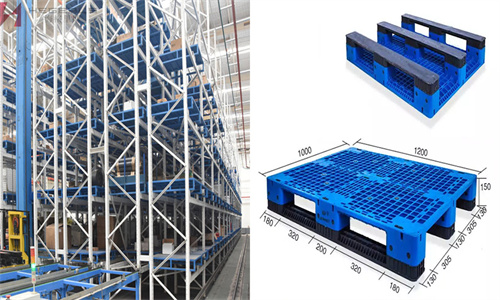

*Pallet (container): an appliance used to carry goods, also known as a station appliance.

*Laneway stacker: equipment used for automatic access to goods. It can be divided into two basic forms of single column and double column according to its structural form; According to the service mode, it can be divided into three basic forms: straight, curve and transfer vehicle.

*Conveyor system: the main external equipment of the three-dimensional warehouse, which is responsible for transporting goods to or from the stacker. There are many kinds of conveyors, such as roller conveyor, chain conveyor, lifting table, distribution car, elevator, belt conveyor, etc.

*AGV system: i.e. automatic guided trolley, which is divided into induction guided trolley and laser guided trolley according to its guiding mode.

*Automatic control system: the automatic control system that drives the equipment of the automatic three-dimensional library system is mainly based on the field bus mode.

*Storage information management system: also known as computer management system, is the core of the fully automated three-dimensional library system. Typical automatic three-dimensional library systems use large-scale database systems (such as Oracle, Sybase, etc.) to build a typical client / server system, which can be networked or integrated with other systems (such as ERP system, etc.).

Wherein, the tray belongs to a small logistics appliance. Most people think that the pallet is just a simple instrument without technical content, and they do not know its important role in logistics and even the whole supply chain. In fact, in the logistics industry, pallets can not only ensure the normal flow, effective connection, smooth and complete process of products of upstream and downstream enterprises in the supply chain, but also greatly improve the efficiency of logistics operations and reduce logistics costs. The innovation of pallet production is of great significance to resource conservation and environmental protection.

In the automatic three-dimensional warehouse, the materials are placed in the standard pallet, and the pallet is sent to the specific position of the warehouse body through the intermediate lifting device. The standard pallet can be customized into different forms according to the actual size and nature of the materials to meet the needs of different industries. Scattered spare parts, documents, electronic products, drugs, or high-quality parts can be placed in the tray, and the temperature, humidity, light, etc. in the warehouse can also be controlled to form a library for different purposes, such as spare parts library, document library, library, drug library, constant temperature and humidity Library, cache library, etc.

Speed and efficiency are essential if you want to achieve maximum cargo turnover. When a large number of items are operated in a multi shift system or stored and processed in a limited space, the automatic pallet warehouse always gives play to its advantages. The pallets used with the automated three-dimensional warehouse can reasonably and fully utilize the three-dimensional area of the warehouse, connect with the intelligent system, realize the full automation process, reduce manpower, improve efficiency, make the storage environment more clean and safe, and meet the characteristics of goods such as light protection, low temperature, moisture-proof and anti-corrosion. At the same time, the shelf system, software and all equipment used in the automated pallet warehouse must be perfectly coordinated. Therefore, the planning and implementation of automatic pallet storage should be completed by experienced experts such as hegerls warehousing. The automatic pallet warehouse can be used as a built-in storage device or an independent silo warehouse, with a height of 45m, so the space utilization rate is extremely high. The storage space of the tray, grille box and personalized bearing system can withstand a load of 7.5t. These warehouses are divided into single-layer, double-layer and multi-layer specifications and are applicable to almost all types of products. Used as normal temperature warehouse, temperature controlled warehouse or low-temperature freezing warehouse as low as – 35 ° C.

What are the requirements for automatic three-dimensional library trays?

*Pallet specification is required to be determined in advance

Many customers will take this into account when building the three-dimensional library, so as not to increase the cost later. Only after the pallet size is determined in advance can the specifications of the rear three-dimensional warehouse shelves be prepared, the equipment such as stacker, assembly line and shuttle car be built, and the specifications and sizes of forklift and hydraulic truck be selected. If the specification and size of the three-dimensional library tray do not match the later equipment, the light will waste space, and the heavy will increase the purchase cost.

*Standard size pallet is required

In the industry, the three-dimensional warehouse pallets are mainly Chuan type pallets and Tian type pallets. The Chuan shaped tray also has high feet, chips and planes. At present, the commonly used three-dimensional warehouse pallets include 1200 * 1000 * 150mm, 1200 * 1000 * 160mm, 1200 * 1200 * 15mm, 1200 * 1200 * 160mm and other standard sizes. The standard size pallets have better adaptability, and are more smooth and less prone to collision in the process of storage, turnover and transportation. At the same time, the standard size pallet can reduce the purchase cost. If it is a special size tray, it needs to be customized. Its supporting shelves, stackers, shuttles, assembly lines and forklifts need to be matched with it. The maintenance cost and replacement cost in the later period will undoubtedly increase.

*It is required to reasonably plan the number of pallets

The automatic three-dimensional warehouse has the advantages of high efficiency, high density, high efficiency and high flexibility. It can be built in buildings of various sizes, suitable for standard plastic pallet models, and can be integrated into other systems to optimize the warehouse process. According to the throughput requirements of the three-dimensional warehouse and the storage density of the warehouse, we can consider the selection of cost and performance when selecting pallets. If the number of pallets is reasonably planned, the average utilization rate of the three-dimensional warehouse pallets can reach more than 90%.

*It is required that the load-bearing capacity of the pallet is up to the standard

Many people may not know the load-bearing capacity of the pallet when purchasing the pallet of the three-dimensional warehouse. We should know that the dynamic load, static load and shelf load of the pallet are different. When we select the pallet of the three-dimensional warehouse, we need to consider the cargo load.

*It is required that the bending degree of the tray meets the standard

When the rack on the pallet of the three-dimensional warehouse is used, it needs to be tested for the flexibility. When a certain weight of goods are stacked on the surface of the pallet, the bending degree shall be less than 5%, so that the pallet will not be deformed during actual use.

*It is required that the tray has strong resistance

The three-dimensional warehouse tray shall have strong resistance. Generally, it is required to select the tray produced and processed with food materials, which is resistant to violent impact, chemical corrosion and temperature and humidity change. If it is a three-dimensional storage tray used in the cold storage, it is also necessary to select a special tray for the cold storage, so that the service life of the tray will be longer.

What are the storage environment and use conditions of the automated three-dimensional library tray?

In order to ensure the long-term and safe use of the three-dimensional library tray, it is required to correctly store and use the three-dimensional library tray according to the following requirements:

*The pallet of the three-dimensional warehouse shall be protected from the sun, so as not to cause the aging of the pallet material and shorten the service life.

*It is strictly prohibited to throw the goods on the pallet of the three-dimensional warehouse from a high place. It is necessary to reasonably determine the stacking mode of the goods on the pallet, and the goods shall be placed evenly. Do not stack them in a centralized manner or eccentrically.

*It is strictly prohibited to throw the pallet of the three-dimensional warehouse from a high place or from a low place to a high place to avoid the breakage and crack of the pallet caused by violent impact.

*When the hydraulic truck and forklift use the pallet, the distance between the fork teeth shall be as wide as possible to the outer edge of the fork inlet of the pallet, and the fork depth shall be more than 2 / 3 of the depth of the entire pallet. In the actual operation, keep moving forward and backward and up and down at a uniform speed to avoid damage to the pallet and collapse of goods caused by sudden braking and sudden rotation. The fork teeth shall not impact the side of the tray to avoid breaking and cracking of the tray.

*When pallets are stacked, the goods shall be stacked flatly to make the bottom surface of the pallet under uniform stress, so as to avoid the rupture of the pallet caused by excessive deformation of the pallet.

*When the pallet is placed on the shelf, the pallet shall be placed stably on the shelf beam. The length of the pallet shall be greater than the outer diameter of the shelf beam by more than 50mm. At the same time, the rack type pallet shall be used. The bearing capacity shall be determined according to the shelf structure. Overload is prohibited.

*The built-in steel pipe tray shall be used in a dry environment.

Hegerls is not only a storage service enterprise integrating R & D, production, sales and service, but also a tray supplier integrating the development, production, sales, leasing and service of plastic trays. Its main products include: three-dimensional warehouse trays, three-dimensional warehouse plastic trays, automatic three-dimensional warehouse plastic trays, blow molding trays, RFID chip trays, and loading and unloading free trays. Its products are widely used in food and beverage, medical Chemical fertilizer, logistics, electronics, clothing, glass manufacturing and other industries are widely used. At the same time, haigris storage shelf provides customers with a comprehensive solution for the construction of storage projects: planning and design of automated three-dimensional warehouse and logistics system; Equipment selection and system integration; Investment estimate and cost analysis; Operation efficiency and management level.

Post time: Aug-15-2022