The four-way shuttle technology is a revolutionary technology in logistics warehousing systems. Due to its strong adaptability to the site, the four-way shuttle can operate in six dimensions: front, back, left, right, up, and down. Combined with the layout of the elevator and conveyor system, the spatial layout of the four-way shuttle can be flexibly adjusted, allowing for the utilization of certain irregular and idle spaces, and even connecting different warehouse channels in the park to achieve warehouse sharing, This has obvious advantages in the renovation of old warehouses. Therefore, the four-way shuttle has developed rapidly in recent years due to its advantages of smaller size, more flexible storage, more flexible deployment, and higher adaptability to the site. Especially the box type four-way shuttle, its main purpose is to provide fast access services for “goods to machine” picking. Although its application history is not long, it has attracted widespread attention in the industry and is considered an important component of future intelligent logistics systems.

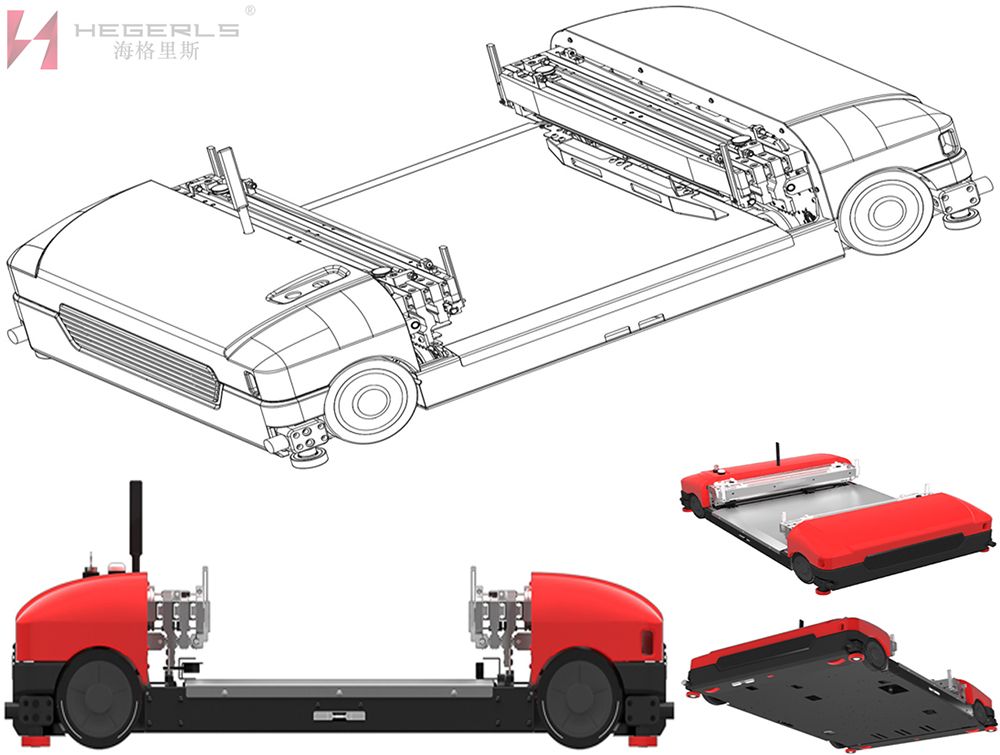

In recent years, Hebei Woke has successively developed ultra-low level four-way shuttle cars and clamp type shuttle cars to meet the demand for unmanned, intelligent, flexible, efficient, and high volume ratio in the market, in order to adapt to the domestic and international demand for ultra-low level, multi specification container warehousing. After the Hebei Woke HEGERLS four-way shuttle system products are stored by users, compared to traditional ground warehouses and forklifts (shelves+forklifts) warehouses, the storage capacity can be increased several times, greatly enhancing the storage space capacity; At the same time, the Hebei Woke HEGERLS four-way shuttle can also achieve 90 ° reversing and self lifting loading and unloading, replacing humans with machines, thereby reducing production and operating costs for the enterprise. Equipped with intelligent equipment such as elevators, silos, and conveyor lines, the efficiency of the four-way shuttle has been greatly expanded.

The Four Way Shuttle (HEGERLS) is a 3D intelligent shuttle developed by Hebei Woke to alleviate the pressure of enterprise warehousing and distribution. By programming, tasks such as accessing and transporting goods can be achieved, which can be perfectly coordinated with the logistics information system (WCS/WMS) to achieve automated identification, access, and other functions. The maximum cargo weight can reach 50KG, and it uses advanced supercapacitor power supply. Charging for 10S can meet the needs of the shuttle car’s 3MIN usage, greatly improving the equipment’s energy utilization efficiency. The intelligent system scheduling and kinetic energy recovery system enable the product to achieve intelligent collision avoidance function, and the path planning of multiple vehicles on the same floor also makes the user’s warehouse more flexible and intelligent. The maximum efficiency of entry and exit for a single roadway can reach over 1000 boxes per hour.

Since Hebei Woke HEGERLS entered the domestic and international markets, its core product intelligent four-way shuttle business has successfully partnered with major logistics integrators. Hebei Woke has collaborated with well-known domestic and foreign brands such as cross-border e-commerce, shoe and clothing e-commerce, and 3C Electronics to provide one-stop intelligent logistics services such as products, technology, and after-sales services. The cases are widely used in more than 20 sub industries such as medicine, automobile, retail, e-commerce, library, rail transit, sports, manufacturing and third-party logistics.

Innovative Application of HEGERLS Box Type Four Way Shuttle System in Clothing Manufacturing Warehouse

The Hebei Woke HEGERLS box type four way shuttle car system manages semi-finished fabric pieces. The four way car supplies empty material boxes in the cutting workshop and stores the cut fabric pieces. According to the empty box demand of the cutting workshop, empty boxes are taken out of the warehouse, and full boxes of fabric pieces are stored in the four way shuttle car warehouse. In the warehouse, the warehouse management system is used to match the demand of materials. According to the material demand plan of the clothing workshop, the material integrity analysis is carried out to determine the location of the bin where all kinds of cloth pieces are located. When the clothing workshop’s demand plan is released, the warehouse issues goods in order according to the demand. The clothing workshop pulls the task of semi-finished fabric sheets leaving the warehouse based on the operation situation on the clothing production line, and at the same time, returns empty material boxes to the warehouse in a timely manner. Through the launch of the four-way shuttle system on site, the timely and accurate entry and exit of materials can be achieved while meeting the high warehousing rate and information management requirements of the warehouse.

Customer pain points and expectations

1) The warehouse is low, irregularly shaped, and has low floor capacity;

2) High efficiency requirements for inbound and outbound operations, with significant changes;

3) The pressure on one-time investment funds is high, and I hope to go online in installments.

Project effectiveness

The Hebei Woke HEGERLS box type four-way shuttle system can well adapt to special application environments such as low warehouses, irregular shapes, and low floor load, and can meet the high efficiency requirements of inbound and outbound operations with significant changes in efficiency. Due to the flexible project expansion and equipment addition of the four-way vehicle system, it can meet the needs of customers to go online in stages and batches, reducing investment pressure on customers.

Highlights of the project plan

Application scenario of the material box four-way shuttle system: It can be widely used in warehousing centers in industries such as e-commerce, clothing, and medicine.

Dispatching system: Hebei Woke HEGERLS box four-way shuttle scheduling system can conduct global optimization of tasks according to the task status and the current running status of four-way shuttle, maximize the overall efficiency of the four-way shuttle system, and meet the use needs of the storage system with the most economical input.

Multi choice warehouse layout: A fast shuttle system can be placed anywhere in the upper and lower spaces of the factory building, with low requirements for the height of the factory floor and suitable for irregularly shaped warehouse areas;

Energy saving: Compared with traditional handling equipment, the material box type four-way vehicle consumes less energy in a single handling operation due to its lightweight body. At the same time, through the energy recovery technology of the four-way vehicle, the energy during the deceleration process can be recovered, further reducing system energy consumption;

Space saving: Under the same processing capacity, fewer tunnels are required, reducing the use of space and reducing the floor area;

Flexible, modular, and highly expandable: it can meet the handling requirements of single vehicles at any position on the same floor through flexible lane changing functions; It can work together with multiple machines on the same layer, meeting the peak inbound and outbound operation requirements during the actual use of the project. The system can also perform lean configuration of equipment according to the actual business development needs of users;

Hebei Woke provides integrated services such as logistics center process layout plan, logistics key equipment planning and selection, equipment control platform and control system, project landing plan, project management, and supporting after-sales support, providing full process intelligent logistics transformation and upgrading services, empowering enterprises with supply chain value effectiveness, meeting the daily and major business needs of 2B and 2C businesses, and providing soft power support for marketing growth of major enterprises.

Post time: Apr-24-2023