As the customer demand in chemical fiber industry further tends to be personalized and customized, there are more and more SKU, and the logistics operation scenarios are constantly changing, which have high operation efficiency, make full use of space, can travel in multiple directions across the roadway, and are configured with flexible four-way shuttle cars and stackers and other automatic intensive warehouses, which are favored by more and more enterprises.

About HEGERLS

Hebei Walker Metal Products Co., Ltd., formerly known as Guangyuan Shelf Factory, was an earlier company engaged in the shelf industry in North China. In 1998, it began to participate in the sales and installation of warehousing and logistics equipment. After more than 20 years of development, it has become a one-stop integrated service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

It also established its own brand "HEGERLS", established production bases in Shijiazhuang and Xingtai, and sales branches in Bangkok, Thailand, Kunshan, Jiangsu and Shenyang. It has a production and research and development base of 60000 m2, 48 world advanced production lines, more than 300 people in R&D, production, sales, installation and after-sales service, including nearly 60 people with senior technicians and senior engineers. The products and services of HGRIS cover nearly 30 provinces, cities and autonomous regions in China. The products are exported to Europe, America, the Middle East, Latin America, Southeast Asia and other countries and regions, and have made remarkable achievements overseas.

HEGERLS is a professional automated warehouse design and equipment manufacturer, as well as a professional shuttle car, stacker and other manufacturers. It is committed to providing customers with cost-effective automated warehouse planning and overall equipment solutions. As a well-known manufacturer with technical patents for equipment related to automated warehouse, HEGERLS has provided more competitive prices and excellent services for most warehouses, as well as cost-effective intelligent logistics equipment and management systems. Customers served by automated warehouse come from many fields such as chemical, food, medical, machinery, cold storage, etc. The products of HEGERLS:

Storage shelf: shuttle shelf, cross beam shelf, four-way shuttle car shelf, pallet four-way shuttle car shelf, medium shelf, light shelf, pallet shelf, rotary shelf, through shelf, stereoscopic warehouse shelf, attic shelf, floor shelf, cantilever shelf, mobile shelf, fluent shelf, drive in shelf, gravity shelf, high storage shelf, press in shelf, pick out shelf Narrow aisle type shelf, heavy pallet shelf, shelf type shelf, drawer type shelf, bracket type shelf, multi-layer attic type shelf, stacking type shelf, three-dimensional high level shelf, universal angle steel shelf, corridor type shelf, mold shelf, dense cabinet, steel platform, anti-corrosion shelf, etc.

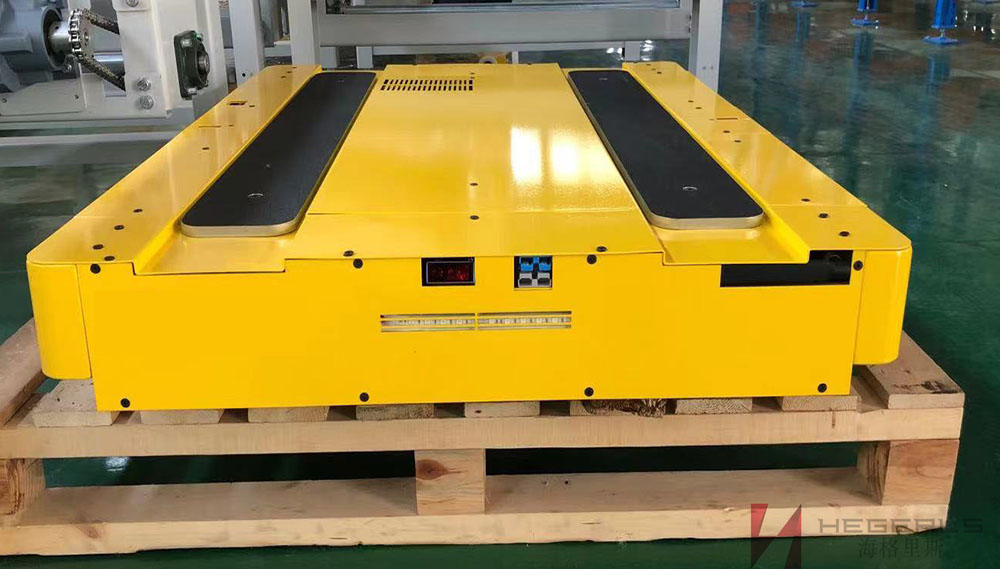

Storage equipment: steel structure platform, steel pallet, steel material box, smart fixed frame, storage cage, isolation net, elevator, hydraulic pressure, shuttle car, two-way shuttle car, parent shuttle car, four-way shuttle car, stacker, screen partition, climbing car, intelligent transportation and sorting equipment, pallet, electric forklift, container, turnover box, AGV, etc.

New intelligent robot series: Kubao robot series, which includes: carton picking robot HEGERLS A42N, lifting picking robot HEGERLS A3, double depth bin robot HEGERLS A42D, telescopic lifting bin robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42 SLAM, multi-layer bin robot HEGERLS A42, dynamic width adjusting bin robot HEGERLS A42-FW, intelligent management platform, workstation Smart Charge Point.

Automated stereoscopic warehouse: shuttle stereoscopic warehouse, beam stereoscopic warehouse, pallet stereoscopic warehouse, heavy shelf stereoscopic warehouse, automated warehouse stereoscopic warehouse, attic stereoscopic warehouse, layer stereoscopic warehouse, four-way shuttle car stereoscopic warehouse, mobile stereoscopic warehouse, narrow roadway stereoscopic warehouse, unit stereoscopic warehouse, through stereoscopic warehouse, cargo format stereoscopic warehouse, automated cabinet stereoscopic warehouse, strip shelf stereoscopic warehouse, picking stereoscopic warehouse, semi-automatic stereoscopic warehouse Linear guideway stereo warehouse, U-guideway stereo warehouse, traverse guideway stereo warehouse, low floor stereo warehouse, middle floor stereo warehouse, high floor stereo warehouse, integrated stereo warehouse, layered stereo warehouse, stacker stereo warehouse, circulating shelf stereo warehouse, etc.

Warehouse management system: order management system (OMS), warehouse management system (WMS), warehouse control system (WCS) and transportation management system (TMS). The warehouse management system provided by HEGERLS can promote the efficiency improvement and cost reduction of the whole chain, and realize the real "intelligent warehouse configuration integration".

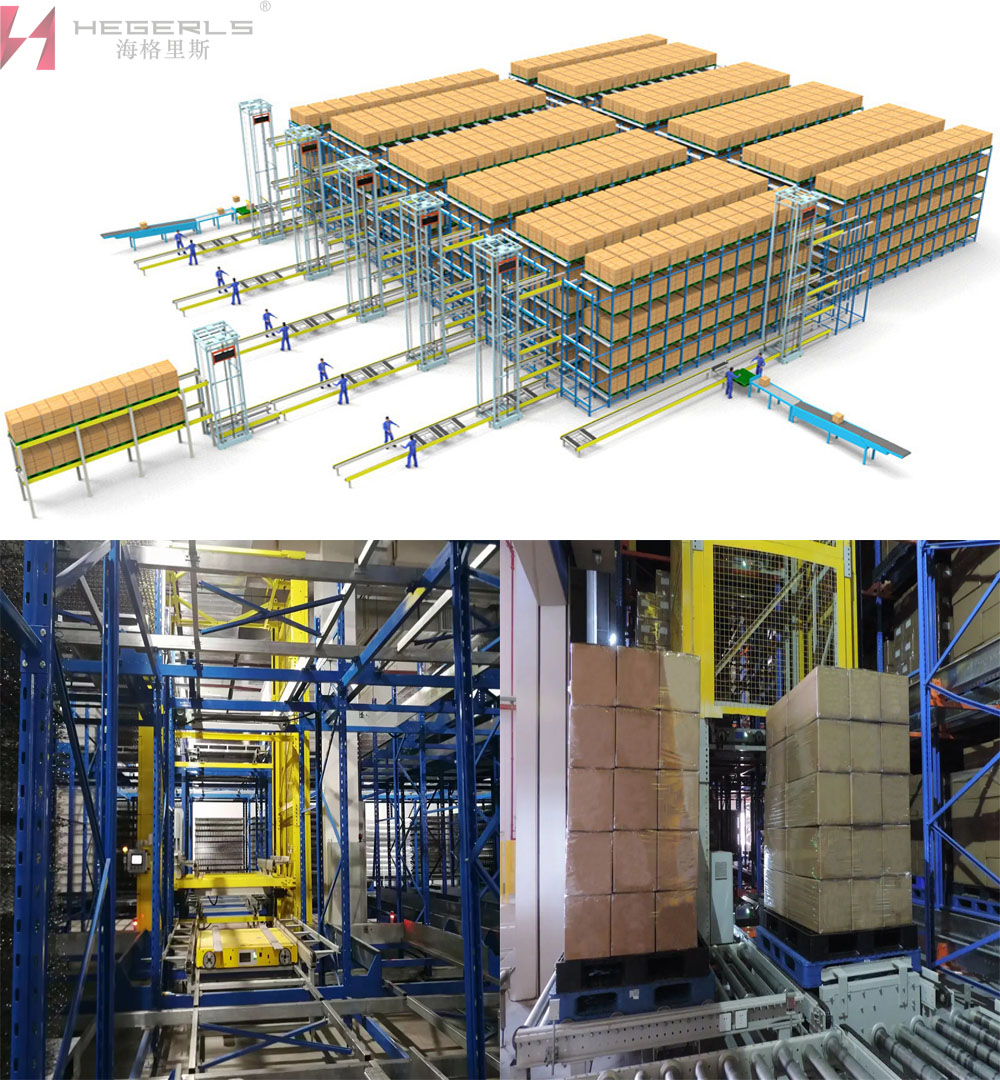

Structural Layout of Four way Shuttle Car of Haggis Roadway Stacker

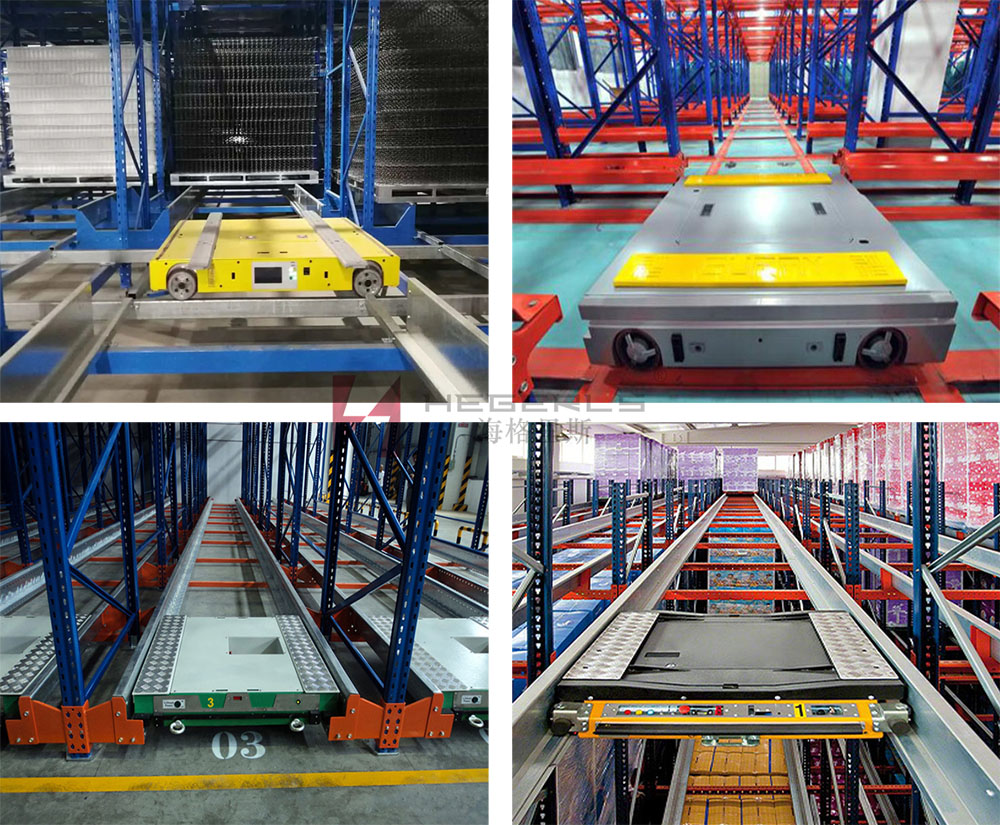

The combined intelligent storage system and control method of the stacker and four-way shuttle can maximize the space utilization, and the equipment operation path is independent and does not interfere with each other. The optimization of the transportation path is achieved through the planning of the warehouse area. A combined intelligent storage system of stacker and four-way shuttle car. The storage system is equipped with a shelf area and a sorting area. A horizontal stacker track and a stacker are set between the shelf area and the sorting area. There are several multi-layer track type shelves arranged in the shelf area. A zero disk storage area and a warehousing and outbound buffer area are set near the stacker track in the shelf area, A shuttle car cycle track and a four-way shuttle car running on the shuttle car cycle track are installed between the multi-layer track type shelves, and a whole plate warehousing area is set at one end of the warehousing buffer area; One side of the sorting area close to the track of the stacker is equipped with a zero removal buffer area, and the zero removal buffer area is horizontally separated with a loose disk buffer area and an outbound conveying area. Several conveyors are longitudinally installed in the outbound conveying area and the loose disk buffer area, respectively. The end of the outbound conveying area is transversely installed with a jack transfer machine, and the other side of the zero removal buffer area is equipped with a zero removal robot and a longitudinal zero removal and loading conveyor belt, The zeroing buffer area is also connected with an empty tray recycling conveyor belt and a longitudinal warehousing conveyor belt.

At the same time, the stock in/stock out buffer area includes the stock in buffer area and stock out buffer area set at horizontal intervals. The stock in buffer area corresponds to the bulk disk buffer area, and the stock out buffer area corresponds to the stock out transport area. In the four way shuttle car of the Haggis roadway type stacker, most of the stackers are lifting double extension stackers. (Of course, there are also single extension stackers, which can be selected according to customer needs.) A barcode recognition scanner is also installed in the position of the zero removal robot. The four-way shuttle car system of the Haggis tunnel type stacker also includes the warehouse management system, which is connected with the four-way shuttle car, the stacker and the disassembly robot.

How does the four-way shuttle car of the Hagrid Roadway Stacker work?

When the goods are stored in the warehouse, the whole pallet of goods is transported to the whole pallet storage area of the shelf area through the warehousing conveyor belt and the stacker, and then the whole pallet of goods is transported to the corresponding multi-layer rail rack for inventory by the four-way shuttle car; When picking up goods, the four-way shuttle car will transport the whole pallet of goods from the multi-layer rail rack to the inbound and outbound buffer area, and the stacker will transfer the goods to the outbound transport area of the zeroing buffer area, and then transfer them to the parts removal robot through the conveyor and the jacking transfer machine, and the parts will be removed in whole by the parts removal robot, and the remaining parts will continue to be transported to the parts removal buffer area until they are removed repeatedly when waiting for the next delivery order, At the end of each shipment, the remaining loose trays will be transferred to the inbound and outbound buffer area through the stacker, and then the loose tray goods will be transferred and stored in the zero tray storage area of the shelf area by the four-way shuttle. Before the whole plate is disassembled by the disassembly robot, the information of the whole pallet of goods is confirmed after scanning by the barcode scanner, and the quantity of the goods is confirmed according to the order information. Furthermore, the order goods after the disassembly of the disassembly robot are transferred to the loading position through the disassembly and loading conveyor belt. When the empty pallet is disassembled by the disassembly robot, it will be transferred and recovered from the empty pallet recycling conveyor belt, stacked by the pallet stacker and then stored in the warehouse again via the warehousing conveyor belt.

The biggest advantage of the four-way shuttle car of the Haggis roadway stacker is that it adopts a modular design with strong robustness, that is, the problem of a single point will not cause the problem of the entire warehouse; Strong scalability, easy to change the deployment at any time, and easy to iterate the work process according to business changes. The buffer in the shipping area, the robot disassembles the remaining spare disks, and the buffer between the spare disks and the empty trays are collected and stacked, and the management also forms a circular channel; A cycle flow structure is also formed between the batch warehousing buffer areas and the stacker.

The 4-way shuttle car of the Haggis lane type stacker can realize the whole process outbound operations such as stacking and warehousing by industrial robots, buffered batch outbound, buffered batch destacking, temporary storage of the remaining bulk trays, collection and management of empty trays, and realize the functions of anthropomorphic sorting, distribution of goods, zeroing and returning to the warehouse. Using the detection and analysis technology of wms, wcs, and plc, the 4-way shuttle car and the stacker can change layers up and down, Realize the flexible and fast process control system of goods in and out of the warehouse. The shelves are assembled in modules, which can realize multi-layer warehouse.

Post time: Dec-06-2022