The material box type four way shuttle robot is a type of robot used for material box storage and retrieval. It can complete storage and retrieval tasks at any storage location through cross roadway and cross layer operations, and flexibly adjust the number of shuttle cars configured in the system to meet storage and retrieval needs. It breaks the design concept of stacking machine mode in three-dimensional warehouses, greatly improves space utilization and access efficiency, facilitates system expansion, and is widely used in the market.

The material box type four-way shuttle car is similar to the pallet type four-way car in that it has a wide range of adaptability, which can be applied to various warehouse types, and can also flexibly increase or decrease the number of cars to match actual needs. As an extension of the usage scenario of the box type two way shuttle system, the material box type four way shuttle system has the characteristics of high-density storage, high flexibility sorting, good scalability and adaptability, rapid deployment, safety and reliability. During the overall system operation, the box type four-way shuttle can reduce the reliability of a single product on the system, allowing multiple processes to operate in parallel. When the order demand changes, the system can flexibly mobilize vehicles from adjacent layers and alleys to concentrate work.

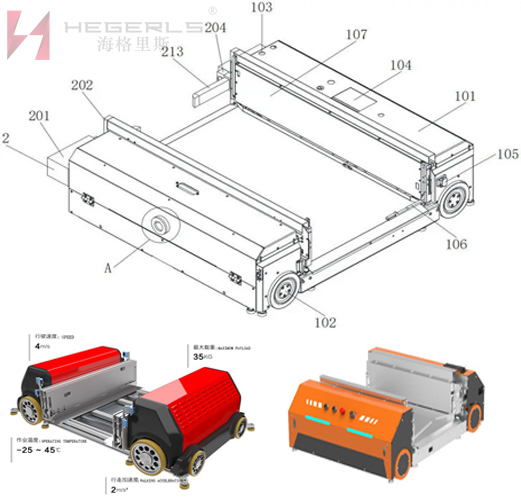

Hebei Woke HEGERLS, as a smart warehousing and logistics system and equipment integrator, has been deeply involved in the field of smart warehousing and logistics for over 20 years. The intelligent equipment independently developed and produced has been deeply applied in warehouse management work with convenient, diversified, and intelligent services. It has rich implementation and application experience in many industries such as cold chain, chemical fiber, food, medical, manufacturing, and new energy. Taking the box type four-way shuttle car as an example, Hebei Woke has conducted comprehensive iterative updates on the product performance, scheduling algorithm, and efficient operation rate of the shuttle robot. The Hebei Woke HEGERLS material box type four-way shuttle is widely used in the “goods to people” picking solution due to its advantages of being more intelligent, flexible, and integrated.

The characteristics of the HEGERLS material box type four-way shuttle car are as follows:

*Modularization and flexibility

We provide various models of HEGERLS material box type four-way shuttle cars, including static, telescopic, and belt type shuttle cars, for supplementing plastic boxes and cardboard box flow shelves. This system is suitable for building configurations, including existing low top box buildings. Additional shuttle cars can be easily added to provide higher throughput.

*Efficient, accurate, and reliable

The HEGERLS bin type four-way shuttle system operates in an efficient “no light” environment, designed specifically for mission critical applications, is easy to maintain, and can achieve high normal operating times.

*Extremely high throughput rate

The dual cycle, straight through, and series elevator configurations (combined with high-speed shuttle cars and intelligent control systems) provide quick access to inventory and can handle up to 1000 items per hour of material.

*High density storage

Multi depth intelligent storage of plastic boxes and cardboard boxes of different sizes can ensure space utilization in refrigerated or frozen environments.

Highlights of the HEGERLS Bin Type Four Way Shuttle Solution

1) Bin type four-way shuttle robot+layer changing elevator

The material box type four-way shuttle robot uses the material box layer changing elevator to achieve layer changing and tunnel changing, completing flexible operations of four-way driving and flexible reciprocating. The material box layer changing elevator, with its advantages of fast speed, stable driving, and strong bearing capacity, helps the warehouse to meet high flow in and out of storage needs.

2) Box type four-way shuttle robot+high-precision three-dimensional shelves

Compared to traditional flat warehouses, automated three-dimensional warehouses can increase the storage capacity by 4-5 times, maximize space utilization, and meet dense storage needs, even in irregular or irregular warehouses.

3) Bin type four-way shuttle robot+warehouse management system

The material box shuttle robot can communicate with the upper computer or WMS system to achieve flexible control of storage space and inventory. It can also optimize order processing capabilities by deploying multiple robots in each shelf lane to meet the requirements of high throughput operations and achieve intelligent operations under high throughput requirements.

Hebei Woke has also solved many warehouse warehousing problems for major enterprises in recent years due to its unique four-way shuttle intelligent dense storage system and unique solutions. The Hebei Woke HEGERLS material box type four-way shuttle car can automatically switch between longitudinal storage tunnels and transverse transfer channels in a 90 degree direction, making it more suitable for warehouse storage modes in complex terrain environments. Due to the interconnection of various single machines and units in Hebei Woke with wireless network support, it is only under the scheduling of the WMS/WCS upper management and control system that the first in, first out or first in, last out inbound and outbound work of materials can be coordinated and completed. The Hebei Woke HEGERLS material box type four way shuttle vehicle dense storage system is composed of a horizontal conveying system, a shelf system, a four way shuttle vehicle, a fast vertical elevator, and a WMS/WCS management and control system. The biggest advantage of this system is that it has high storage density, stable system operation, and high safety redundancy, which also has strong scalability for the later entry and exit inventory efficiency. The Hebei Woke HEGERLS material box type four-way shuttle has been widely used in industries such as textile shoes and clothing, refrigeration, automotive parts, e-commerce logistics, hardware and building materials, equipment manufacturing, and military supplies.

Post time: May-29-2023