With the rapid development of the logistics industry, the pallet four-way shuttle rack three-dimensional warehouse has developed into one of the mainstream forms of warehousing logistics due to its advantages of efficient and intensive storage function, operation cost and systematic and intelligent management in the circulation and storage system. In recent years, the hegerls intelligent pallet four-way shuttle shelf has won the favor of many enterprises, and has accumulated certain application experience in new energy, intelligent manufacturing, medical, footwear and other industries. So, enterprise customers who have not yet put into use the four-way pallet shuttle shelf of haigris should ask how haigris can ensure that the four-way pallet shuttle shelf system can operate efficiently? Now, from the characteristics and functional design of the pallet four-way shuttle shelf, haigris specifically analyzes and answers how haigris can ensure the efficient operation of the pallet four-way shuttle shelf system?

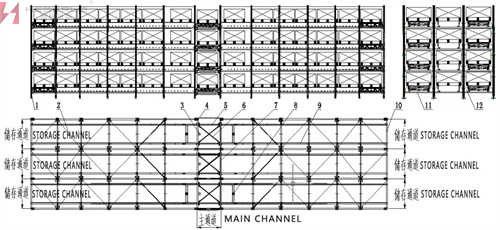

The pallet four-way vehicle rack is a pallet four-way shuttle rack, which is mainly composed of upright pieces, supporting beams, sub rails, parent rails, pull rods, end supports, reversing rails, etc.

1 – column piece 2 – horizontal tie rod of sub track beam 3 – photoelectric positioning support 4 – protective rail at the end of main channel 5 – reversing rail 6 – cross tie rod of reversing rail 7 – main track (ramp) 8 – charging pile 9 – sub track (tunnel) 10 – protective rail at the end of sub channel 11 – supporting beam 12 – end support

The pallet four-way shuttle automatic dense storage system is a new automatic storage system solution. It can realize a variety of automatic storage functions through flexible configuration. It can be configured as a dense storage shuttle rack, a laneway automatic three-dimensional warehouse rack, and a variety of transportation systems. The system is suitable for the automatic transformation of low warehouse, warehouse with too many columns and warehouse with irregular shape. According to the actual operation efficiency requirements, the number of equipment can be reasonably configured according to the needs, so as to solve the disadvantages of high maintenance cost and complex mechanical structure of the existing automatic three-dimensional warehouse.

Q: as an intelligent logistics equipment provider, what are the characteristics of the pallet type four-way intelligent shuttle rack designed and produced by hegerls?

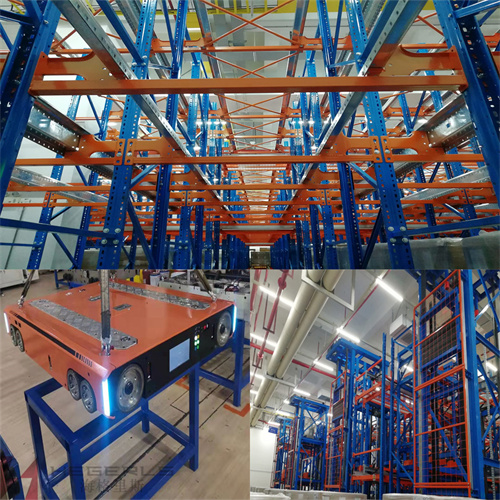

1) The pallet four-way shuttle has a compact structure: small height and size, saving more storage space; It can not only travel in four directions on the supporting rack track, but also use the vertical elevator to realize the layer changing operation, which further increases the flexibility and scalability of the warehouse rack layout and the operation in the four-way shuttle garage.

2) Four way travel: it can travel along the vertical or horizontal tracks on the three-dimensional rack crossing track to realize one-stop point-to-point transportation, and can reach any location on the warehouse floor;

3) Intelligent layer replacement: with the help of higris elevator, the shuttle car can realize the efficient working mode of automatic and accurate layer replacement; Realize three-dimensional movement in space and accurately control the warehousing and outbound of each cargo location in the steel shelf area;

4) Intelligent control: it has automatic and semi-automatic working modes. It greatly improves the efficiency of goods entering and the space utilization of the warehouse. The docking of WMS and WCs system software with enterprise ERP / SAP / MES and other management system software can also maintain the first in first out method of goods storage, and eliminate the disorder or low efficiency of human factors;

5) High utilization rate of storage space: the density of traditional warehouse storage is low, resulting in low utilization rate of total warehouse area and low utilization rate of warehouse volume; The pallet four-way shuttle car runs in four directions on the main track in the rack, and can complete the operation independently without the coordination of forklift and other equipment. Since the volume of the main track of the rack is smaller than the volume of the forklift operation channel, the pallet four-way shuttle automatic dense storage system can further improve the utilization rate of storage space compared with the ordinary shuttle car rack system, which can generally increase by 20% ~ 30%, which is 2 ~ 5 times that of the ordinary flat warehouse;

6) Dynamic management of cargo location: the traditional warehouse is only the place where goods are stored, and the storage of goods is its only function. It is a kind of “static storage”. The pallet four-way shuttle car is an advanced automatic material handling equipment, which can not only make the goods automatically stored in the warehouse according to the needs, but also organically connect with the production links outside the warehouse, so as to form an advanced logistics system and improve the management level of the enterprise;

7) Unmanned automatic warehouse model: it greatly reduces the workload of warehouse staff and provides the possibility of unmanned work in the warehouse. The three-dimensional warehouse for product delivery is directly connected through the pallet four-way round-trip machine, the vertical lift for goods and the automatic conveyor. The warehouse staff only need to monitor the operation of the system at all times to realize access automation, and there is no need to enter the warehouse for operation. It is especially suitable for storage of warehouses that are not suitable for long-term detention of personnel, It is the development direction of high-density storage and automatic warehouse in the future.

8) Temperature environment: the pallet four-way shuttle shelf manufactured by hegerls can also achieve two environmental modes: normal operation under high-temperature storage and low-temperature storage.

9) Safety performance: adopt multi-level hardware and software combined monitoring measures, set safe operation distance and judgment principles, and ensure the safe operation of the whole vehicle through specific operation limit blocker or anti overturning mechanism.

Q: in addition to the above features, what are the features of the shelf of the four-way pallet shuttle in the specific functional design to ensure the efficient operation of the shelf system of the four-way pallet shuttle?

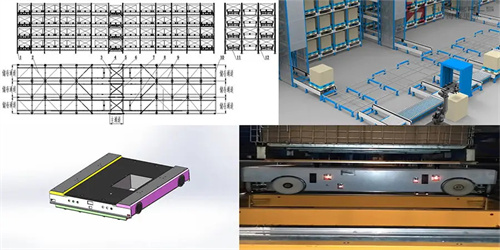

The rack of the four-way shuttle truck of haigris pallet has a unique dual motor start and deceleration mode, which can realize stable operation under high acceleration and deceleration. At the same time, it also has a special dual charging mode of direct charging and wireless charging. The direct charging mode is suitable for common production environments; Wireless charging mode is suitable for dust-proof and explosion-proof environment.

The functional design features of the rack of the four-way shuttle truck of haigris pallet are as follows:

Breakpoint continuation: when the vehicle is performing the loading and unloading task, due to short-time non hardware failure such as obstacle avoidance and network disconnection, the vehicle will automatically continue to perform the unfinished task without human intervention after waiting in the original position until the abnormality is eliminated.

Automatic charging & return to work: when the vehicle is lower than the set low battery value, the relevant battery information will be automatically uploaded to WCs, and WCs will dispatch the vehicle to perform the charging task. After the vehicle is charged to the set power value, the relevant power information will be automatically uploaded to WCs, and WCs will dispatch the vehicle to resume the task.

Pallet perception: the vehicle has the functions of pallet centering calibration and pallet detection

Obstacle perception: the vehicle has obstacle perception function in four directions, and it can avoid obstacles at a long distance and stop at a short distance.

Battery temperature sensing: it detects the battery temperature in the vehicle body in real time. When the battery temperature exceeds the set high limit, it feeds back the abnormal battery temperature information to WCS in real time. WCS dispatches vehicles to the special station outside the warehouse to avoid fire.

In situ reversing function: realize in-situ reversing of the vehicle body by replacing the corresponding wheels on both sides.

Four way travel: it can travel in four directions of the dedicated track of the three-dimensional warehouse and reach any designated location of the warehouse under the WCS dispatching.

Position calibration: Multi-sensor Detection, supplemented by two-dimensional code of the tunnel, to achieve accurate positioning.

Intelligent dispatching control mode: WCS online automatic dispatching mode, manual remote control operation mode and maintenance mode.

Sleep & wake up mode: after long-time standby, enter sleep mode to save power. When it needs to run again, it will wake up automatically.

Emergency power supply rescue: under abnormal conditions, when the battery power is zero, use the emergency power supply, turn on the motor brake, and move the vehicle to the corresponding maintenance position.

Status display & Alarm: status display lamps are installed at many places of the vehicle to clearly indicate various operating states of the vehicle. A buzzer is installed to give an alarm in case of vehicle failure.

Charging detection: when the vehicle reaches the charging position, charging abnormality occurs during charging, and the abnormal information is fed back to the WCS in real time.

Vehicle shock absorption: special polyurethane wheels are used for pressure resistance, wear resistance, pressure resistance and shock absorption.

Post time: Aug-25-2022