With the diversification and complexity of logistics center business types, the pallet type four-way shuttle vehicle three-dimensional warehouse, as a new automated storage technology, has gradually entered the field of vision of major enterprises. The professional configuration of the tray type four-way shuttle system, as an upgrade of the tray type two way shuttle technology, can carry out multi-directional driving, efficient and flexible operation across tunnels, without being limited by space and fully utilizing space. And more and more tray type four-way shuttle vehicle three-dimensional storage projects have been successfully put into use in various industries.

About Hebei Woke HEGERLS

In recent years, Hebei Woke Metal Products Co., Ltd. has gradually emerged in the warehousing industry. Hebei Woke Metal Products Co., Ltd. was founded in 1996, formerly known as Guangyuan Shelf Factory. It was one of the earliest companies in the shelf industry in North China, and began to intervene in the sales and installation of warehousing and logistics equipment in 1998. With years of experience in intelligent storage solutions, we have become an advanced enterprise in intelligent storage shelves and equipment both domestically and internationally. The development strategy of Hebei Woke Metal Products Co., Ltd. is: high-precision shelf business (core business)+integration business (strategic business)+service business (emerging business). As the core business of our company, the high-precision shelf business will continue to maximize customer benefits through strict material selection, excellent craftsmanship, and advanced cost control methods. As a strategic business of our company, the integration business includes advanced technologies such as parent vehicle system, four-way shuttle technology, multi-layer shuttle technology, ground light AGV technology, ground heavy AGV technology, cargo to person picking system, WMS (warehouse management system software), WCS (equipment control software) system, as well as rotary shelf system and light four-way shuttle developed and manufactured in recent years Heavy four way shuttle cars, elevators, stackers, and Kubao robots (such as cardboard picking robot HEGERLS A42N, lift picking robot HEGERLS A3, double deep bin robot HEGERLS A42D, telescopic lifting bin robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42M SLAM, multi-layer bin robot HEGERLS A42, etc.) have continuously enriched the variety of automated single machine products, In order to further improve the "shelf+robot=storage system solution", Hebei Woke's independent brand is HEGERLS, with a series of products and services covering nearly 30 provinces, cities, and autonomous regions in China. The products are exported to countries and regions such as Europe, America, the Middle East, Latin America, and Southeast Asia, and have achieved remarkable results overseas. They are also sold domestically, and provide customers with more intelligent and efficient storage solutions. As an emerging business, service business focuses on efficiency, informatization, traceability, and automation to meet the future market demand of logistics warehousing centers. It also provides customers with better added value from the perspective of improving equipment system performance and optimizing customer investment costs.

Storage Equipment - Main Structure of the Hagrid HEGERLS Tray Four Way Shuttle Dense Storage System

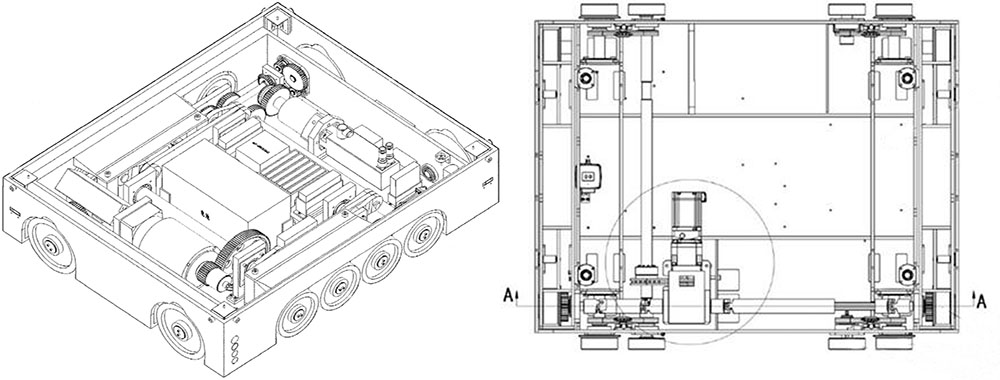

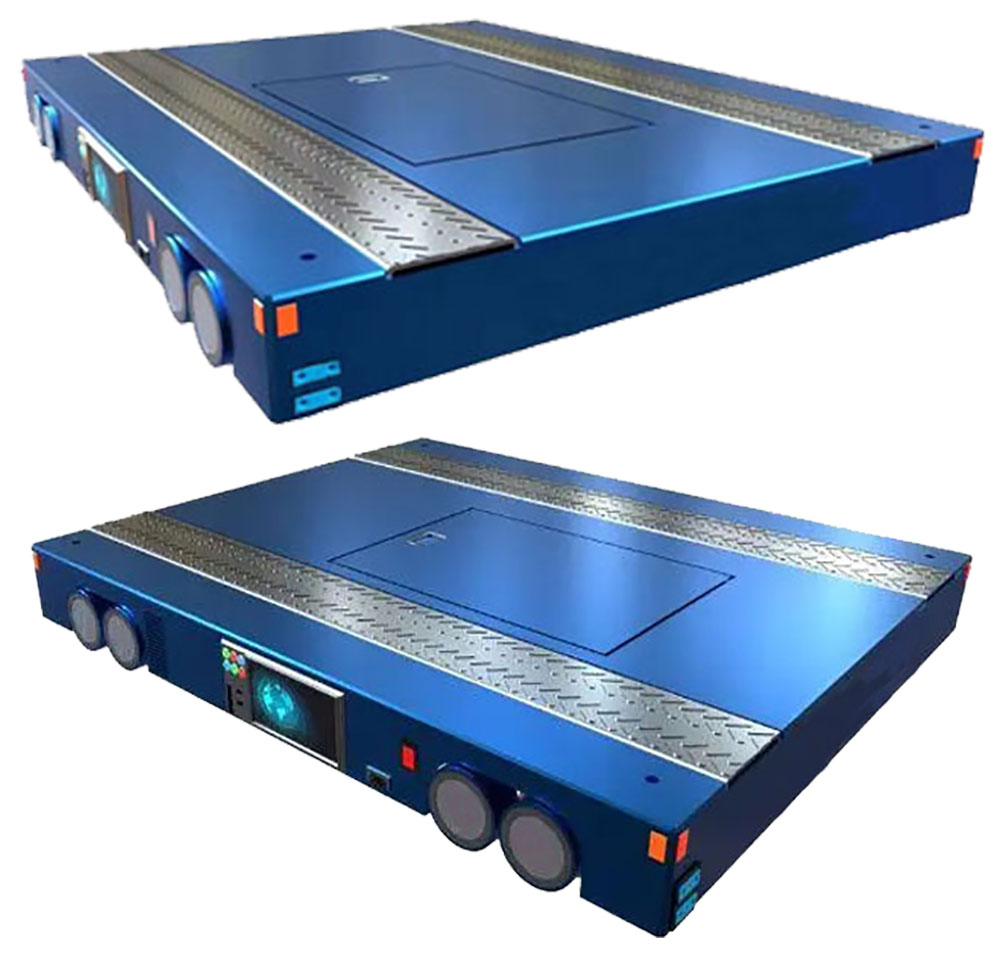

The biggest feature of the HEGERLS pallet four-way shuttle car is that it achieves the thinnest hydraulic drive structure in the entire industry, with a height of only 126mm, even thinner than the entire machine of the two way shuttle car. It can effectively compress the space occupied by equipment in the shuttle car layer, providing customers with better solutions for efficient utilization of three-dimensional storage space, and successfully implementing case libraries in multiple industries. The core equipment of the tray four-way shuttle type automated dense storage system includes a tray four-way shuttle car, a dedicated vertical elevator, and supporting shelves. The tray four-way shuttle car has a compact structure, fast running speed, and adopts wireless communication. Multiple tray four-way shuttle cars work in a group form and can cooperate to meet the application needs of different places. The pallet four-way shuttle car can not only travel in four directions on the supporting shelf tracks, but also use vertical elevators to achieve layer changing operations inside the shelves, improving the flexibility of shelf layout and warehouse operations.

HEGERLS New Energy Case - Zhejiang New Energy Equipment Co., Ltd. Pallet Type Four Way Shuttle Project

For this new energy project case, the warehousing solution provided by Hebei Woke is to use the Hagrid HEGERLS tray type four-way shuttle vehicle dense warehousing system to store goods, with 4 shelves and a total of 304 storage spaces. Four main lanes, one tray type four-way shuttle vehicle, and one four-way vehicle vertical conveyor are planned.

Project difficulties and solutions:

Difficulty 1: The height of the goods is 2750mm, and high cargo is prone to overturning during transportation in the warehouse area;

Warehouse solution: In response to the difficulties raised by the enterprise, Hebei Woke proposed through monitoring various data in the on-site warehouse, which can be avoided through high-performance single machine equipment and high-precision shelves. The handling equipment such as the Hagrid HEGERLS pallet type four-way shuttle and the Hagrid HEGERLS elevator operate smoothly, have stable performance, and high shelf production and installation accuracy.

Difficulty 2: Insufficient concentrated load on the warehouse floor

Due to the fact that the warehouse of the enterprise is a building and there is a parking garage underneath, there may be a problem of insufficient concentrated load on the ground of the warehouse. The solution adopted by Hebei Woke is to lay H-beams on the ground, connect them into a steel mesh, and place the HEGERLS shelf column feet on the steel mesh, effectively reducing the concentrated load on the ground and solving the problem of insufficient ground load.

Overall, the tray four-way shuttle system has applications in industries such as manufacturing and cold chain. In addition, for old industrial parks and warehouses with limited variety and large cargo volume, a tray four-way shuttle system can also be considered to fully utilize the height space of the warehouse, release more economic production capacity, and create value for customers.

Post time: Sep-13-2023