Roller conveyor is an important modern bulk material conveying equipment, which is widely used in power, grain, metallurgy, chemical industry, coal, mining, port, building materials and other fields. It is also because of its wide range of conveying materials, wide range of conveying capacity, strong adaptability of conveying route, flexible loading and unloading, strong reliability and low cost. It has gradually replaced automobile and locomotive transportation in some fields, becoming the main equipment of bulk material transportation, and playing an increasingly important role in the social and economic structure. For this reason, Hergels warehousing has gradually entered this field for the different needs of major enterprises. At the same time, after long-term strict control, it produces different types of conveying and sorting equipment to provide more convenient warehousing services for its majority of enterprises. Let’s follow the steps of haggis herls to learn more about the roller conveying equipment produced by haggis herls.

What is heigris hegerls roller conveyor?

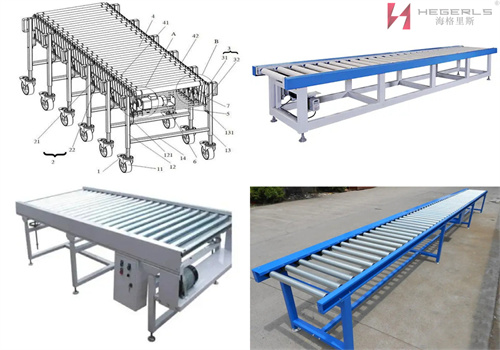

The roller conveyor is a series of rollers supported in the frame, which can manually move objects by gravity or power. At the same time, the roller conveyor is also a friction driven machine that transports materials in a continuous manner. It can form a material conveying process from the initial feeding point to the final unloading point on a certain conveying line, that is, it can convey broken materials and finished goods, In addition to pure material transportation, it can also cooperate with the requirements of the technological process in the production process of various industrial enterprises to form a rhythmic flow line. The roller conveyor system can be configured for use with a range of auxiliary equipment, including elbows, gates, and turntables. Among all kinds of conveying equipment, roller conveyor has a very common scope of application and a solid position that can not be ignored. Roller conveyors are widely used in express delivery, postal services, e-commerce, airports, food and beverage, fashion, automobiles, ports, coal, building materials and other manufacturing industries.

Structure composition of hegerls drum conveying equipment

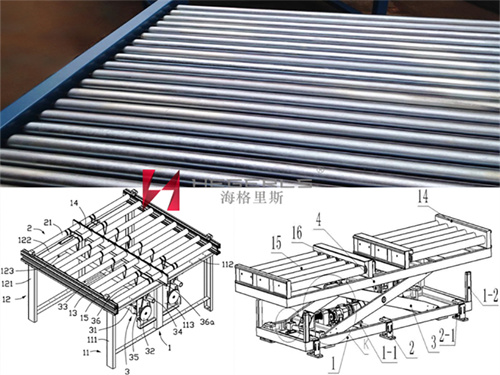

The roller conveyor is mainly composed of rollers, frames, supports, driving parts, etc. the roller conveyor relies on the friction between the rotating rollers and the articles to move the articles forward. According to its driving form, it can be divided into unpowered roller conveyor and powered roller conveyor In the power roller conveyor, the method of driving the roller is generally not to drive alone, but to drive in groups. Usually, the motor and reducer are combined, and then the roller is driven to rotate through chain drive and belt drive.

Features of hegerls drum conveyor of hagris

1) Simple structure, high reliability, easy to use and maintain.

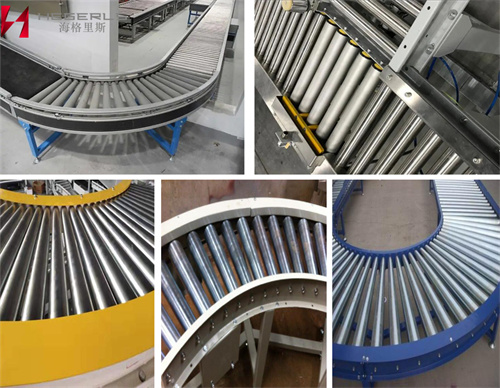

2) There are various structural forms. According to the driving mode, the roller conveyor can be divided into power roller line and unpowered roller line, and according to the layout form, it can be divided into horizontal conveyor roller line, inclined conveyor roller line and turning conveyor roller line. It can also be specially designed according to customer requirements to meet the various requirements of various customers.

3) The roller conveyor is suitable for the transportation of various boxes, bags, pallets and other pieces of goods. Bulk materials, small items or irregular items need to be placed on pallets or turnover boxes for transportation.

4) The roller conveyor can transport materials with large single weight or bear large impact load.

5) It is easy to connect and transition between drum lines. A complex logistics transportation system can be formed by multiple drum lines and other transportation equipment or special machines to complete various process needs.

6) The stacking roller can be used to realize the stacking and conveying of materials.

7) Efficient and stable, ensuring production efficiency;

8) It can realize a variety of complex transportation, supporting a variety of machines;

9) Smooth transportation and reduce the damage of manually handled products;

10) Lower cost creates higher value for the enterprise.

Detailed parameters of Hercules Hegels drum conveying equipment:

Roller specification and diameter: 25mm\38mm\50mm\76mm\89mm\110mm\130mm

Roller length: 100mm-1000mm (customized according to customer requirements)

Roller material: generally divided into galvanized type, nickel plated type, PVC coated type, stainless steel type;

Conveying speed: determine or adopt frequency conversion adjustment or constant speed according to customer needs;

Safe operation of hegerls drum conveying equipment

1) Turn on the main power switch of the roller conveyor, and check whether the power supply of the equipment is sent normally and whether the power indicator light is on. Proceed to the next step after normal operation.

2) Turn on the power switch of each circuit of the roller conveyor and check whether it is normal. Generally, the normal state is: the equipment does not act, the operation indicator light of the roller conveyor is not on, the power indicator light of the frequency converter and other equipment is on, and the display panel of the frequency converter is normal (no fault code is displayed).

3) The roller conveyor starts all electrical equipment in turn according to the process flow. After the start of one electrical equipment on the roller conveyor is normal (the motor or other equipment has reached normal speed and normal state), the next electrical equipment can be started, and the components of the equipment should be lubricated regularly during the work of the power roller conveyor.

Hercules hegerls drum conveyor selection knowledge

1) Selection of roller length: for goods with different widths, rollers with suitable width should be selected. Generally, “conveyor +50mm” should be used;

2) Selection of the wall thickness and shaft diameter of the drum: the weight of the conveyor is evenly distributed to the contact drum, and the required load of each drum is calculated to determine the wall thickness and shaft diameter of the drum;

3) Roller material and surface treatment: determine the material and surface treatment used by the roller according to the different transportation environment (carbon steel galvanization, stainless steel, blackening or rubber coating);

4) Choose the installation mode of the drum: according to the specific requirements of the overall conveyor, choose the installation mode of the drum: spring press in type, internal tooth shaft type, full flat tenon type, through shaft pin hole type, etc; For the conical drum of the bending machine, the rolling surface width and taper depend on the cargo size and turning radius.

Generally speaking, the roller conveyor is suitable for the conveying of various regular objects. The complex conveying system composed of roller conveyors with different shapes can also be matched with the screw conveyor independently developed by our factory to meet some special conveying requirements, which can be designed and manufactured according to customer requirements.

During the production and operation of the drum conveyor line, there are many reasons for the slippage. The following haggis herls will talk about the common problems and treatment methods in the operation:

1) The load of the conveyor belt of the roller conveyor line is too large, which exceeds the load capacity of the motor, so it will slip: at this time, the transportation volume of the transported materials should be reduced or the bearing capacity of the conveyor itself should be increased.

2) The starting speed of the roller conveyor line is too fast to cause slippage: at this time, it should be started slowly or restarted after jogging twice again, which can also overcome the phenomenon of slippage.

3) The initial tension is too small: the reason is that the tension of the conveyor belt when leaving the drum is not enough, resulting in the slippage of the conveyor belt. At this time, the treatment method is to adjust the tensioning device and increase the initial tension.

4) The bearing of the drum is damaged and does not rotate: the reason may be that there is too much dust accumulation or there is no timely maintenance and replacement of the parts that have been seriously worn and do not rotate flexibly, resulting in increased resistance and slipping.

5) The slipping phenomenon caused by insufficient friction between the pulley of the conveyor drive and the conveyor belt: the reason is mostly that there is moisture on the conveyor belt or the working environment is wet. At this time, a little rosin powder should be added to the drum.

Post time: Jul-22-2022