Storage robot refers to the robot used for goods handling, sorting, picking and other operations, mainly including automatic guided vehicle (AGV), autonomous mobile robot (AMR) and manipulator. Among them, AGV and AMR mobile robots are mainly responsible for the task of automatically transporting items from the starting point to the destination, while the manipulator is mainly used in the links such as destacking and sorting. From the perspective of application scenarios, storage robots are mainly used in industrial manufacturing and commercial circulation. At the same time, the storage robot is mainly used to improve the handling efficiency, replace manpower for heavy and dangerous work, and better connect with the production line, so as to realize intelligent warehouse management and timely respond to production needs. The storage robot can realize the automatic handling and sorting of goods by means of “automatic picking” and “information management”.

[application scenario of storage robot]

In practical application, AGV, AMR and other mobile robots in warehousing and logistics robots have become the main force in the work. However, the manipulator is restricted by high cost and low mobility, and its application degree is relatively low. However, in the long run, the manipulator can realize accurate identification and flexible sorting in combination with 3D smart camera, AI vision algorithm and other technologies, and can be widely used in the construction of “unmanned warehouse” in the future, so it has greater development potential. In addition to “arming” the manipulator, the cutting-edge technology represented by artificial intelligence is reshaping the warehousing and logistics robot industry chain. The traditional storage robot industry chain is relatively long, including multiple participants such as core parts, body manufacturing, system integration, end customers, etc., with high technical barriers and complex production processes. However, with the progress of artificial intelligence technology, the traditional industrial chain is becoming more flexible.

[Hegels Hegels heavy release]

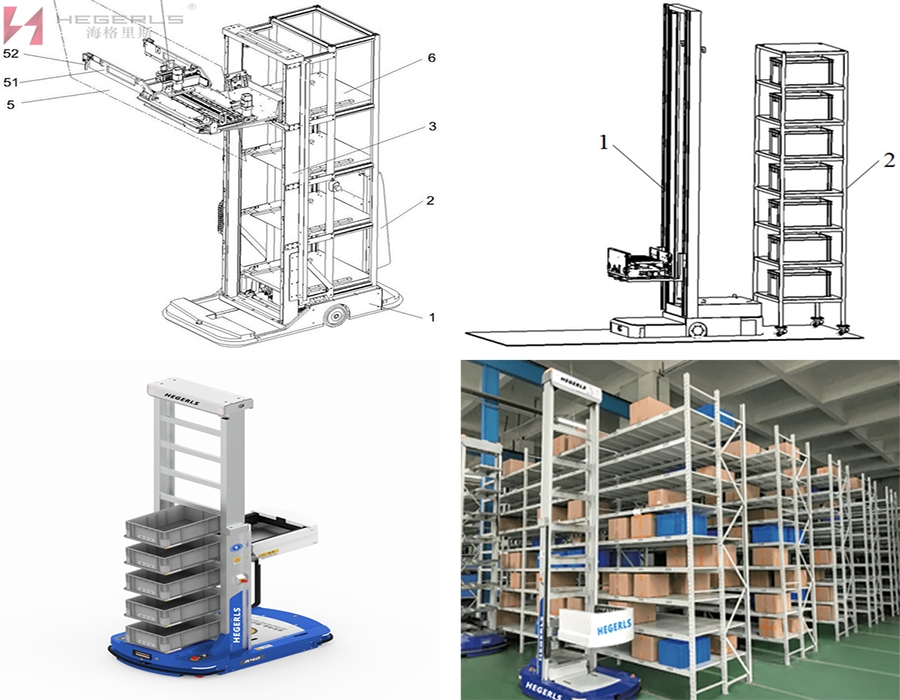

Hagerls, the pioneer and leader of the autonomous case handling robot system (ACR), has renewed its industry recognition and launched the multi-layer case handling robot hagerls A42.

Hegerls is the pioneer and navigator of the box storage robot (ACR) system. It is committed to providing efficient, intelligent, flexible and customized storage automation solutions through robotics and artificial intelligence algorithms, creating cost value for each factory and logistics warehouse. Kubao system under the company is the first box storage robot (ACR) system developed and put into commercial use at home and abroad. Recently, as a leading enterprise in the field of intelligent logistics, Hegels storage shelf supplier has independently designed and developed the second generation Hegels A42 series box storage robots, which marks a new height in the commercial safety standards of Hegels and is a milestone for the company to expand its business at home and abroad.

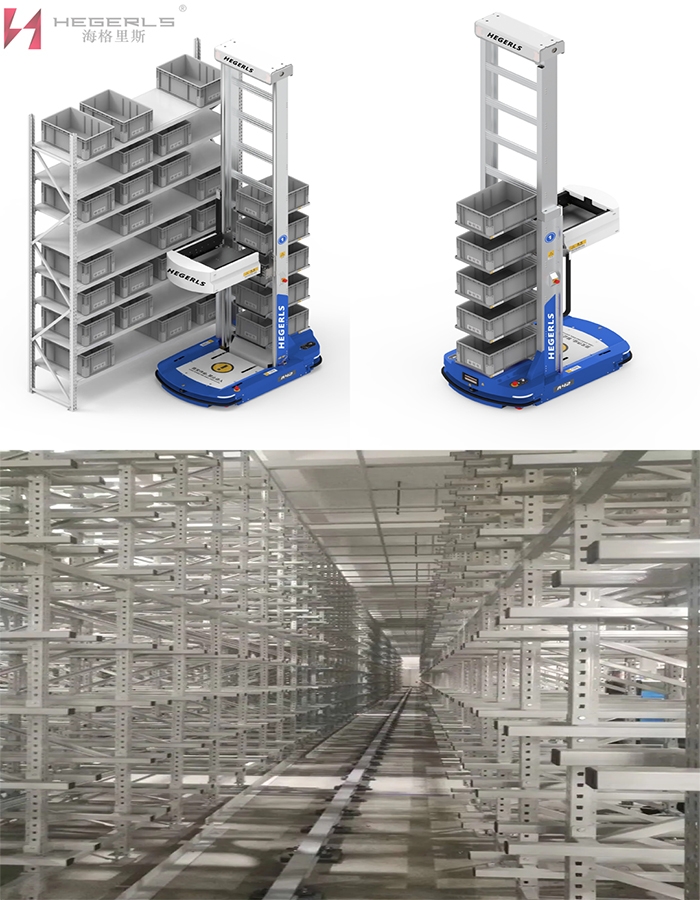

Hegerls A42 multi-layer material box robot is the second generation of multi-layer material box robot independently developed by haggis, which can realize intelligent picking and storage of material boxes and simultaneous handling of multiple material boxes (the maximum load of a single trip can reach 300kg). As a new intelligent logistics handling equipment, hegerls A42 can realize intelligent walking in the storage space without the help of any track equipment. It has the functions of autonomous navigation, active obstacle avoidance and automatic charging. Compared with the traditional AGV “shelf to person” solution, the hegerls A42 multi-layer bin robot has smaller picking granularity. According to the order requirements issued by the system, it truly realizes the transformation from the traditional “people looking for goods” to the efficient and simple “goods to person” intelligent picking mode. Compared with the solutions of stacker and automatic three-dimensional warehouse, the hegerls A42 multi-layer bin robot system can be deployed efficiently, with low overall deployment cost and stronger flexibility; At the same time, hegerls A42 supports docking with a variety of logistics equipment, including shelves, latent AGVs, robotic arms, multi-function workstations, etc. The flexible and flexible product design brings more operating space for the customized scheme, comprehensively improves the storage operation efficiency, optimizes the storage density, and realizes the automation and intelligent transformation of the storage industry.

Applicable scenario: applicable to warehousing applications in 3PL, shoes and clothing, e-commerce, electronics, electric power, manufacturing, medical, retail and other industries.

Working principle of multi-layer bin robot hegerls A42:

The multi-layer bin robot hegerls A42 directly carries the containers hit by the order to the workers’ hands. The workers can easily complete the outbound operation according to the visual operation instructions, which greatly reduces the operation difficulty of the workers and greatly improves the efficiency of picking operation.

Functional characteristics of multi-layer bin robot hegerls A42:

1) Standard height: 4.33M, 1m-5.5m, flexible customization;

2) Multi container handling, single machine access handling up to 8 containers;

3) Full load / no-load moving speed up to 1.8m/s;

4) The goods shall be accurately taken and placed, and the control accuracy of taking and placing shall be ± 3mm.

5) The picking accuracy rate is up to 99.99%, which solves the picking problem that it is difficult to find goods manually and is easy to find mistakes.

Advantages of multi-layer bin robot hegerls A42:

1) The efficiency of man-machine cooperation has been greatly improved

The hit rate is 99.99%; Increase work efficiency by 3-4 times

2) Efficient deployment and rapid ROI

Create an automated and intelligent storage space with high cost performance;

3) Flexible extended multi equipment unified scheduling

Flexible customization, expansion and handling according to actual business scenarios;

4) Scientific and technological innovation and efficient utilization of storage space

The vertical utilization rate of 6m warehouse is as high as 85%, which is 150% higher than that of traditional manual warehouse.

At present, the application of intelligent logistics technology is more and more in-depth, making the logistics operation more agile and efficient. Hagerls storage providers are constantly cooperating with industry changes to upgrade their products, and are committed to providing better intelligent logistics solutions for customers at home and abroad.

Relevant news recommendations:

Hegerls Robotics For Warehouse Automatic Solution

Post time: Jun-28-2022