In recent years, with the rapid development of the cold chain logistics industry, more and more logistics enterprises pay attention to the cold storage. The energy consumption, investment cost and efficiency of the warehouse have always been the pain points in the cold storage. Therefore, it has become a new direction for the development of the cold storage to select the storage system with compact access space and timely service time. As a new compact storage system, the mobile shelf storage system only needs to set aside a picking lane for the access trolley to operate, and then the access trolley moves out of the lane, and then the access trolley enters the lane to complete the goods in and out of the warehouse. The storage system is simple in structure, high in space utilization and low in cost, and has been widely used in various cold storages at home and abroad.

Hegerls

Hagerls is one of the large-scale manufacturers specializing in the planning, design, manufacturing, installation and consulting services of storage rack systems and automated three-dimensional storage racks in China. It has production equipment for various high-end storage rack products, including high-precision rolling equipment for various profiles, continuous precision CNC punching, standard sections and supporting walls, welding units, and automatic electrostatic powder spraying production lines, It has a domestic leading production system for high-end shelf products.

In strict compliance with the requirements of ISO9001 international quality management system, the company has developed, designed and produced automatic three-dimensional warehouse shelves, beam type shelves, shelf type shelves, cantilever type shelves, fluent type shelves, through type shelves, tray type shelves, shuttle type shelves, attic type shelves, drive in type shelves, electric mobile shelves, steel structure platforms, pallets, labels, boxes, storage cages The workbench is specialized in the production and processing of hydraulic lifting and other high-end shelf and storage equipment products. Our products are widely used in tobacco, medical, e-commerce, books, machinery manufacturing, automobile, clothing, beverage, food, cold chain, logistics, daily necessities, third-party logistics and other industries for logistics storage and distribution needs, with a wide range of applications. The integrity, strength and product quality of haigris have been recognized by the industry after years of development.

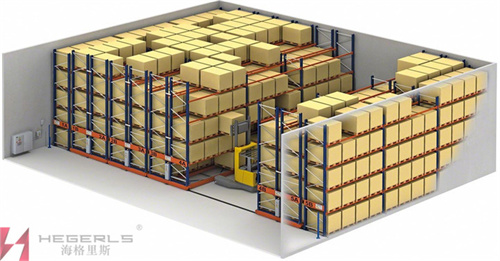

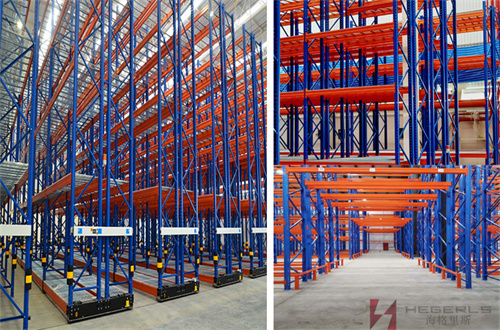

About haigris electric mobile shelf

The electric mobile shelf is one of the high-density storage shelves. It evolved from the pallet type shelf and has an open shelf structure. Only 1-2 channels need to be opened. This kind of shelf has a high space utilization rate and goods are transported by forklift trucks. Generally, there are two types, i.e. trackless and trackless (magnetic guidance). The rack can be controlled by a single unit, or the computer can be used for centralized control. The electric mobile shelf is driven by the motor to carry the trolley. The trolley is placed with beam type shelves, cantilever shelves and other variable-frequency speed regulation. The shelves are very stable from starting to braking, and the safety is greatly guaranteed. This kind of rack has frequency conversion control function, which can control the speed when driving and stopping to prevent the goods on the rack from shaking, tilting or dumping. A photoelectric sensor for positioning and a brakable gear motor are also installed at the appropriate position, which improves the positioning performance. The device is installed on the guide base that slides horizontally, and it does not need to fix the aisle for many times. As shelves and shelves of shelves are moved, aisles are only opened when the operator requests access. Electric mobile shelves are mainly used for the storage of raw materials, industrial products, food or beverage, molds and other items in the factory, and can also be used in logistics warehouses or frozen warehouses. According to the use environment, it can be divided into normal temperature type, freezing type and explosion-proof type. Among them, the freezing type can be used in the cold storage at minus 30 degrees.

Haigris cold storage mobile shelf

Because the cost and operation cost of the cold storage are higher than that of the normal temperature storage, the shelves of the cold storage are usually dense shelves, that is, the so-called three-dimensional shelves. The storage shelves commonly used in cold storage are mainly through type shelves, shuttle type shelves and automatic three-dimensional warehouses. Because of the low cost of mobile shelves, simple structure, strong, beautiful and durable, they can be used for both mobile storage and goods turnover, and are welcomed by the owners. The temperature of the cold storage is generally below – 16 ° C, so the thermal insulation performance of the cold storage and the rationality of the storage rack design are also very critical. The former can reduce the power cost, while the latter can reduce the cost in terms of increasing the storage capacity of the cold storage and improving the efficiency of goods in and out of the warehouse. In terms of material selection of the mobile shelf used in the cold storage, although the performance of Q235 can be met, it is better to select the material with low stress and good toughness, which is as close to the theoretical performance of Q235 as possible.

On the allocation of moving shelves in cold storage

The location allocation problem is the key problem of the mobile shelf storage system for the cold storage, which is directly related to whether the warehouse can operate efficiently and stably. How to optimize the operation efficiency of the mobile shelf storage system for the cold storage and improve the stability of the shelf through a reasonable location strategy is also the research goal of hegerls in recent years.

The location allocation method of the mobile shelf storage system for cold storage is to allocate the items with strong correlation to the same picking lane, reduce the possibility of opening the picking Lane many times, take the similarity coefficient of the order items as the basis of the correlation, and comprehensively consider the frequency of item picking and the center of gravity of the shelf, establish a multi-objective location allocation optimization model, and then use the improved invasive weed algorithm to solve the problem to obtain the optimal storage location of the goods, The greedy algorithm is used to generate part of the initial population, and then a reasonable spatial diffusion operator is set. Finally, the evolutionary reversal operation of genetic algorithm is introduced.

Common location allocation strategies include location storage, random storage, near location storage, full turnover rate storage and classified storage. Cold storage logistics has many logistics characteristics, such as a variety of storage, high timeliness requirements, high cost and complex technical requirements. Adopting a reasonable location allocation strategy can improve the response speed of cold storage orders, reduce the cost of cold storage and improve the shelf stability.

Post time: Aug-24-2022