In recent years, with the increasing demand in the market, the warehousing and logistics industry has entered the era of automated system integration. The core equipment has also shifted from traditional shelves to intelligent warehousing equipment+three-dimensional shelves for storage, forming a more automated and intelligent system integrated logistics system. Among them, the material box type four-way shuttle vehicle three-dimensional warehouse storage solution is favored by various industries due to its fast speed and high flexibility.

The material box type four-way shuttle truck three-dimensional warehouse storage solution is an efficient and intelligent new intensive storage mode. It breaks the design concept of the stacker mode in three-dimensional warehouses, greatly improving space utilization and access efficiency. It not only facilitates the expansion of management systems, but also conforms to the widespread application of market demand.

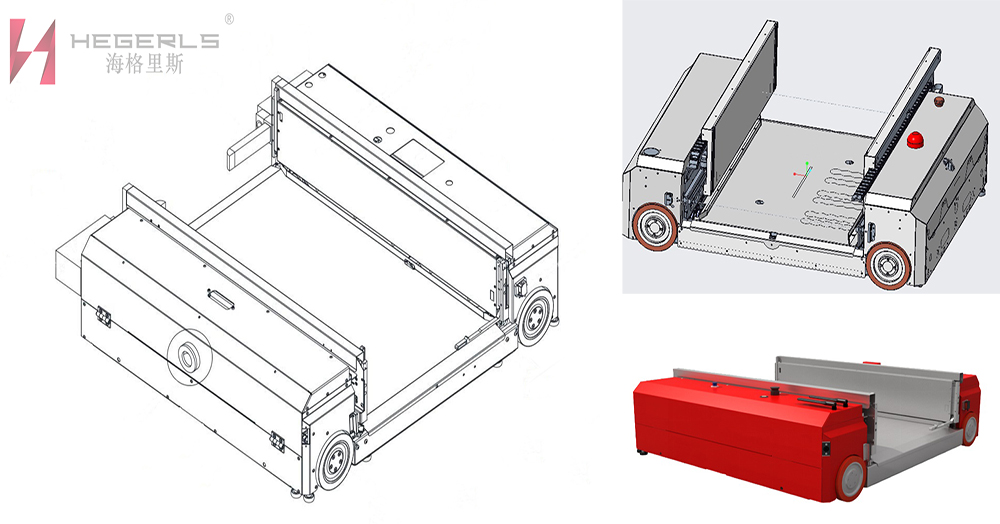

Since 1996, Hebei Woke Metal Products Co., Ltd. has launched its independently developed Hagrid HEGERLS shuttle car product. As of now, Hagrid HEGERLS shuttle cars have covered different series such as tray type shuttle mother cars, box type two way shuttle cars, box type four way shuttle cars, tray type two way shuttle cars, tray type four way shuttle cars, and attic type shuttle cars.

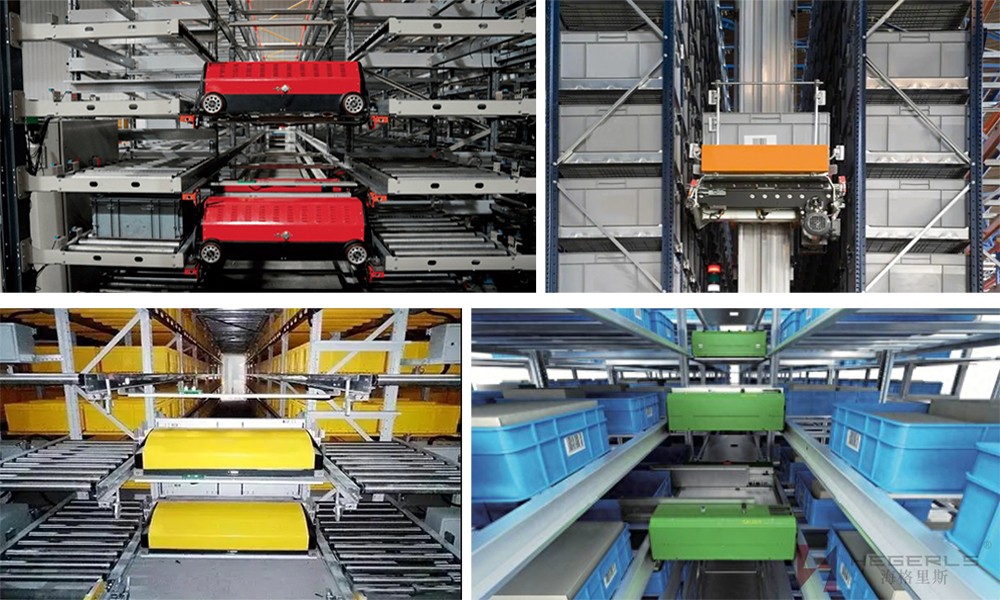

Hebei Woke Metal Products Co., Ltd.'s new generation multi scenario HEGERLS material box type four-way shuttle three-dimensional warehouse storage solution is mainly composed of components such as dense storage shelves, elevators, high-speed cargo elevators, box type four-way shuttle vehicles, drum conveyor lines, and central dispatch systems, suitable for fast access operations of various containers. The HEGERLS material box type four-way shuttle vehicle three-dimensional warehouse solution is widely used in e-commerce, cross-border e-commerce, medical, footwear, fresh food, component production, 3C electronics industry's line side warehouse/raw material warehouse/semi-finished product warehouse/finished product warehouse, as well as some special scenarios such as multi floor warehouses, irregular warehouses, and cross district operations. There are no special restrictions on the venue, and the recommended number of floors is 12-15.

In the Hagrid HEGERLS material box type four-way shuttle car three-dimensional warehouse, the development of the Hagrid HEGERLS material box type four-way shuttle car system was initially mainly aimed at the development of a "cargo to person" sorting system, suitable for application scenarios with multiple changes and sorting varieties. However, with the increasing demand for logistics automation and the increase in the number of automated material boxes, the demand for the four way shuttle vehicle system for material boxes in the current market is gradually increasing. This also makes the advantages of the material box type four way shuttle vehicle in terms of storage efficiency and storage space utilization more prominent, and its application scenarios are constantly expanding.

The HEGERLS material box type four-way shuttle vehicle three-dimensional warehouse solution leads the trend of medical logistics automation

Taking the cooperation project between Hebei Woke and a medical enterprise in Shanxi as an example. A medical enterprise in Shanxi is a third-party logistics storage enterprise in the medical industry, committed to becoming an integrated solution provider for the big health supply chain. The enterprise not only needs to meet the annual circulation scale of medical products; Simultaneously meeting the requirements of providing professional medical supplies, medical devices, cold chain products and other medical third-party logistics services to the outside world. To improve the warehouse capacity, automation, informatization, and intelligence level of customer enterprises, Hebei Woke has combined actual site resources and industry development trends, adopted a cargo to person solution, and created two intelligent four-way shuttle truck box type three-dimensional warehouses. Among them, a total of 13095 storage locations are planned for the room temperature warehouse, equipped with multiple Hagrid HEGERLS box type four-way shuttle cars, box elevators, layer changing elevators, box conveyor lines, WMS, WCS, and other systems to achieve automatic entry and exit of goods, automatic storage, automatic information collection, and safety monitoring functions; And it has achieved rapid sorting of medical supplies dismantling business, greatly increasing the efficiency of personnel sorting operations, reducing the labor intensity of operators, further improving the accuracy of operations, and reducing management costs. The system has strong flexibility features and reserves redundancy. It can achieve a daily picking efficiency of 20000 to 30000 rows by expanding the four-way shuttle.

In the cold storage (2-8 ℃), two Hagrid HEGERLS box type four-way shuttle cars are equipped, as well as box elevators, layer changing elevators, box conveyor lines, WMS, WCS, and other systems. After the system was successfully launched, it effectively reduced personnel's working time in low-temperature environments, improved efficiency, and reduced labor intensity.

In short, the intelligent upgrade of the logistics center project has not only improved the rapid response level of orders, but also improved the service level of customers. Through this project case, Hebei Woke not only fully utilized the characteristics of intelligent logistics equipment, helping the entire logistics supply chain service level of cooperative enterprises to be effectively improved, but also demonstrated the trend of medical logistics automation, providing strong strategic support for future rapid development.

Post time: Sep-07-2023