With the rapid development of e-commerce and the trend of warehousing, logistics, and storage in domestic and international markets, the demand for the logistics industry continues to grow, driving the growth of the pallet four-way shuttle market. The pallet four-way shuttle is an intelligent automation equipment used for pallet freight storage and handling. It can travel back and forth on dedicated tracks and perform bidirectional conversion at nodes. It is an indispensable equipment in the logistics and warehousing industry, which can be used to improve logistics efficiency, reduce operating costs, improve the safety and durability of goods, and increase customer satisfaction. Meanwhile, the performance, durability, and reliability of the pallet four-way shuttle are also key factors determining its market competitiveness.

Hebei Woke is a rare enterprise in the industry that can provide comprehensive logistics and warehousing solutions and implement them. It has the ability to independently research and produce a complete set of core software and hardware, as well as rich experience in overall solution planning and implementation. Since the launch of the first Hegelis HEGERLS four-way shuttle, Hebei Woke has completed the integrated layout of research and development, production, and sales of robot products in all warehousing scenarios with years of logistics experience and continuous technological investment and accumulation. After years of accumulation and development, Hebei Woke’s business has expanded to cover nearly 30 industries. Based on its rich experience in medical, retail, and manufacturing industries, it has also focused on emerging fields such as new energy lithium batteries and semiconductor production. Its core business has developed rapidly. In the warehousing scenario, it can usually be divided into two categories: high standard warehouses with a clearance of more than 5m and floor warehouses with a clearance of less than 5m. High standard warehouses are the focus of traditional intelligent access equipment enterprises. Hebei Woke, with its four-way shuttle system for material boxes, has a first mover advantage in material box vertical warehouses weighing less than 50kg, not only establishing a foothold in the domestic market, but also exporting to overseas markets; The simultaneous launch of storage equipment stackers and the rapidly growing demand for pallet type four-way shuttle systems can also be used to solve the dense storage and retrieval of elevated pallets weighing over 100kg.

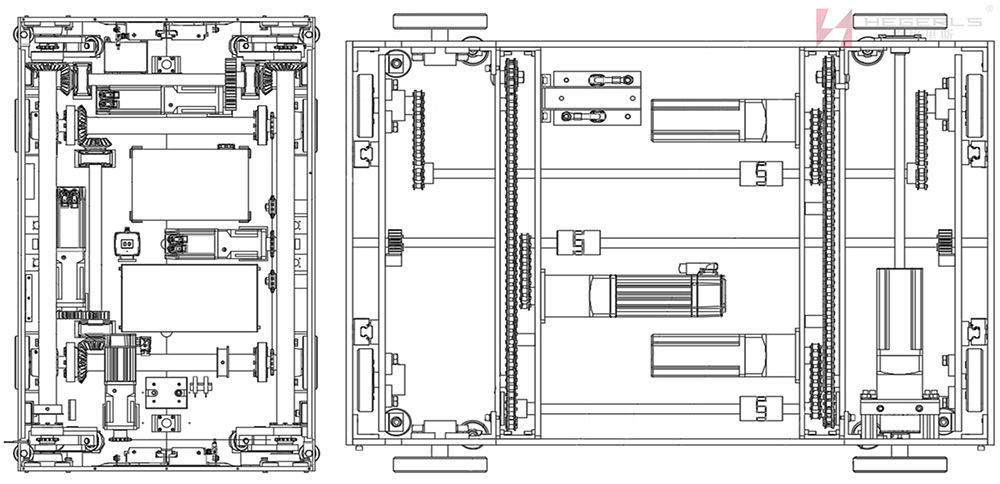

As a new generation flexible logistics solution for pallets, the Hebei Woke Hagrid HEGERLS intelligent pallet four-way vehicle system has advantages such as high-density storage, strong site adaptability, flexible expansion, and short delivery cycles. It can provide physical enterprises with automated and intelligent warehousing solutions with better return on investment (ROI). The HEGERLS tray four-way shuttle car includes two models: a normal temperature tray four-way shuttle robot system and a low-temperature tray four-way shuttle robot system. The normal temperature HEGERLS tray four-way shuttle robot system is suitable for whole piece picking scenarios, such as material finished products, food and beverage, industrial manufacturing and other industries; The HEGERLS low-temperature tray four-way shuttle robot is developed and designed for low-temperature cold storage environments, and can achieve low-temperature unmanned automatic access for operation in cold environments as low as -25 ℃.

The HEGERLS pallet four-way shuttle can achieve automated handling, placement, inbound and outbound operations of goods in a three-dimensional warehouse through system scheduling programs such as WMS, WCS, SAP, MES, etc. It has strong site applicability, flexible layout, high-density storage, and creates a more intelligent storage system.

The dispatch control software is the soul of the four-way garage system. Whether a system is effective or not ultimately depends on the dispatch. How to set the dispatch strategy and whether it is reasonable reflects the manufacturer’s strength. A good scheduling system needs to be able to achieve: real-time calculation of the global optimal path, dynamic allocation of the number of four-way cars on each layer and automatic layer changing of cars as needed, dynamic locking of safety space around four-way cars, and no car deadlock.

Intelligent scheduling algorithm technology for digital twin systems

Software is the soul of intelligent logistics systems, and a warehouse management system with high stability and scalability has become an essential logistics technology in modern logistics centers. The warehouse management system independently developed by Hebei Woke is the “intelligent brain” of the entire logistics center. A powerful software team, after years of research and iteration, has formed a complete set of stand up software product systems, from logistics operations to logistics execution (WMS warehouse management system), intelligent logistics equipment control (WCS warehouse control system), and automated equipment scheduling (RCS robot cluster scheduling system).

The WMS system developed based on the Hebei Woke HEGERLS software development platform allows for rapid secondary development of front-end, back-end, mobile, SQL, reports, and printing. It supports six scheduling strategy configurations at three levels (warehouse, shipper, and material), and most scheduling logic can be solved through configuration. The testing environment supports hot deployment (i.e. change takes effect), enabling fast implementation and adjustment, with strong scalability. In practical projects, the system can automatically analyze the storage situation of goods and command and coordinate various work processes to improve the accuracy and efficiency of operations. It can also collaborate with other subsystems in the warehouse to achieve highly informationized operation of the logistics center. Faced with complex scenarios and customized requirements, the entire process from requirement research to system launch was completed in less than one-third of the time compared to peers, and received full recognition from users.

Based on the business form of each customer, combined with site conditions, material characteristics, storage requirements, inbound and outbound frequency, picking and shipping methods, and enterprise development strategy planning, Hebei Woke provides a full lifecycle service process from pre-sales consulting, planning and design, project implementation to after-sales maintenance, tailoring customized solutions for customers to meet their material storage and circulation needs. Hebei Woke’s warehousing solution covers multiple links such as storage, transportation, handling, and picking, and the system platform can cover the entire process from warehousing to manufacturing. Whether it’s tray, material box storage, or irregular material storage, Hebei Woke can easily handle it and ultimately win the trust of customers with professional and reliable solution design and project implementation.

Post time: Jan-29-2024