With the increase of the demand for logistics automation and the increase of the number of automated bins, the market demand for the bin four-way shuttle system is gradually increasing, which also makes the advantages of the four-way shuttle in terms of storage efficiency and storage space utilization more prominent, and its application field is also expanding. The bin four-way shuttle storage scheme has become an efficient and intelligent new intensive storage mode. It breaks the design concept of the original stacker mode in the three-dimensional warehouse, which greatly improves the utilization rate of the warehouse space and the efficiency of access operations, and better facilitates the system expansion and market application.

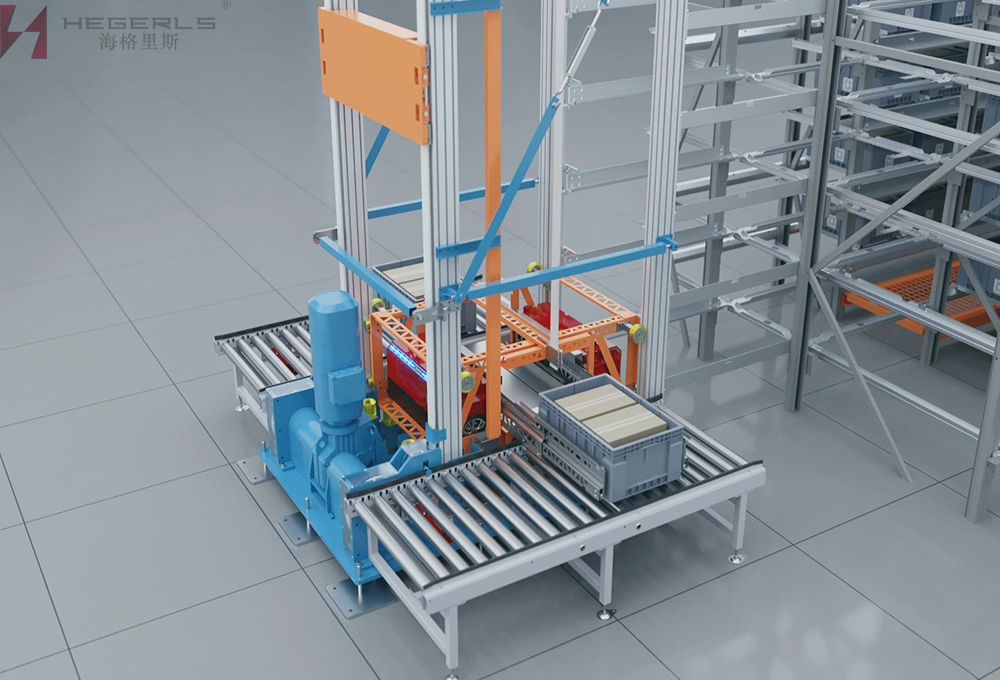

The bin four-way shuttle car is an intelligent transport equipment with the bin as the transport unit. It can complete the access task through cross-roadway and cross-layer operations to any storage location, and flexibly adjust the number of shuttle cars configured by the system to meet the access requirements. The bin four-way shuttle has high application value in industries such as 2C e-commerce, clothing, retail and other industries with multiple categories, high storage capacity and high requirements for disassembly and sorting. The application of box-type four-way shuttle has brought revolutionary innovation to the storage and sorting of a box of goods. The bin four-way shuttle truck storage rack three-dimensional warehouse storage scheme is mainly composed of dense storage rack, elevator, high-speed cargo elevator, box-type four-way shuttle truck, roller conveyor line and central dispatching system. The bin four-way shuttle truck storage scheme is applicable to the rapid access of various containers.

About HEGERLS of Hebei Woke – Haigris

The bin four-way shuttle under the HEGERLS brand of Haigris adopts the deep learning heuristic search algorithm to build a simplified path planning, high-order S-curve planning control technology and 5G communication technology, which ensure the efficiency and safety of the operating equipment; Its core equipment adopts modular and standardized design, which can easily cope with the business expansion of enterprises with high cost performance. At the same time, it can reduce the investment cost of enterprise customers and better optimize resources. The material box four-way shuttle car of HEGERLS brand can be used for all kinds of turnover boxes, cartons and other goods with flat bottom, certain supporting force and not easy to deform.

The HEGERLS box-type four-way shuttle has a wide range of application scenarios and deep industry integration. It is applicable to the small and medium-sized parts split and full box picking scenarios in the warehouses of many industries such as third-party logistics, clothing, medical circulation, 3C, automobile manufacturing, etc. At the same time, HEGERLS also provides the following warehouse storage solutions for major enterprises, as follows:

The first type: cargo to person warehousing solution

The cargo to person storage solution is mainly to realize the access of goods in the pallet mode. This access mode mainly reflects the characteristics of high-density storage to realize the cargo to person.

The second type: container to person storage solution

The container to person storage solution is mainly used for the storage of goods in the automatic three-dimensional warehouse mode, with strong storage capacity; The goods picking mainly refers to small pieces of box-type picking.

Third: order-to-person warehousing solution

Based on the former two, this order-based storage solution is more flexible and adds robot-based storage equipment for operation. This storage solution is more applicable. At the same time, it can carry out new warehouse planning, design, layout, etc. without changing the existing warehouse layout.

Not only that, with the use of the Hagrid HEGERLS brand in major enterprises, it has gradually filled the gaps of major industries in terms of warehousing demand, especially in the manufacturing and circulation industries.

Manufacturing industry – medical industry

Medical logistics has higher requirements on the timeliness of orders and needs to meet the changing strict regulatory requirements. Such higher requirements have brought greater challenges to logistics efficiency. With the accumulated practical experience of various major projects undertaken by Hebei Woke Metal Products Co., Ltd. (brand: HEGERLS) over the years, Hebei Woke has developed a professional logistics research and development, planning, implementation and delivery team. Hebei Woke (brand: HEGERLS) will provide efficient and flexible storage solutions, equipped with low-temperature environment and cross-temperature operation robots, as well as operation systems that meet the mandatory requirements of GSP, GMP, etc., to help the intelligent management of medical logistics, to meet the increasing requirements of circulation efficiency, and will also strictly guarantee its safety and compliance.

Manufacturing – 3C Electronics

3C electronic products generally have the characteristics of small size, multiple varieties, large batches, fast product update and iteration. At the same time, in order to meet the customer’s experience, it also has higher requirements for the accuracy and delivery rate of the logistics system.

Manufacturing – food and dairy products

For the retail industry, there are many kinds of goods, and the traditional logistics management has been difficult to deal with. The problems brought by this management mode are: out-of-stock or out-of-stock situation, order feedback lag, insufficient delivery efficiency, and impact on the user’s shopping experience.

Manufacturing – Manufacturing

The problems faced by the traditional manufacturing industry are: the loss of product line change is high, the production capacity is difficult to adjust, and the market demand cannot be responded quickly and quickly. At the same time, it will also lead to the low efficiency of logistics warehouse operation and the shortage of space resources.

Circulation industry – shoes and clothing

The clothing industry has a large order volume and obvious business fluctuations, and has high requirements on the timeliness and accuracy of picking.

Circulation industry – cold chain

Logistics enterprises often face the problems of low space utilization, low sorting efficiency and high labor costs. In addition, the large number of packages and various destinations have brought great challenges to the accuracy of distribution.

Hebei Woke aims to help manufacturers manage specific needs in the production environment, including effective use of building area, real-time strategy, material flow balance/sequencing, labor ergonomics and high system running time. Through the application of the independent brand HEGERLSAGV and the introduction of the automatic warehouse of the box-type shuttle car, combined with the customer production management system, it effectively solves the burden of the supply of materials on the production line of the production-oriented enterprises, significantly reduces the demand for human resources, effectively reduces the supply inventory, helps customers reduce costs and increase efficiency, and helps to improve the competitiveness of customers in the industry.

For the circulation industry, mature and reliable evaluation measures will be adopted to respond to the pain points and direct needs through systematic research, comprehensively analyze the project characteristics, and put forward a high-matching response plan in combination with the project case model; Based on the results of the project consultation, design the overall logistics plan of the project, and conduct continuous optimization design through process simulation to avoid possible process conflicts and process loopholes; According to the data, process, characteristics and consulting scheme input in the early stage, carry out systematic planning for the whole, output the scheme layout and corresponding node efficiency, and simulate and continuously optimize the process design; And then make insightful judgment on the current situation based on the known information and real-time analysis, and make the best decision and follow-up project implementation based on the analyzed and processed data.

Overall advantages of HEGERLS four-way shuttle

⏵ Stronger modularization

The box-type four-way shuttle can work together with multiple machines on the same floor, and can also meet the peak inbound and outbound operation requirements of enterprises in the actual use process;

⏵ More expansibility

The box-type four-way shuttle system can also carry out lean configuration of equipment according to the actual business development needs of users;

⏵ More flexibility

The box-type four-way shuttle car can meet the handling operation at any position on the same floor of a single car through flexible roadway functions;

⏵ With stronger scheduling

The box-type four-way shuttle vehicle has an intelligent four-way vehicle scheduling system, which can perform global optimization of task operations according to the current task instructions and the current operation status of the four-way vehicle, that is, independently dispatch the idle shuttle vehicle to carry out cross operations and touch each cargo location in the warehouse, thus realizing the overall efficiency of the four-way vehicle system to meet the demand of the storage system;

⏵ Energy saving

Compared with the traditional handling equipment, the body of the box-type four-way shuttle is more lightweight, and its single handling operation consumes less energy. At the same time, it can also use the energy recovery technology of the box-type four-way shuttle to carry out the energy recovery operation during the deceleration process, which reflects the performance advantage of the box-type four-way shuttle with low voltage power supply and less energy consumption;

⏵ Increase the processing capacity

Compared with automated warehouse, the handling of box four-way shuttle vehicles in and out of warehouse has been improved by 3 to 4 times;

⏵ Warehouse layout with more choices

The shuttle car system can be used for rapid layout anywhere in the upper and lower space of the warehouse building, and the requirements for building height are not high;

⏵ Floor area of warehouse

When the box-type four-way shuttle operates, under the same processing capacity, it requires relatively less laneways, which can reduce the use space and reduce the floor area.

Post time: Mar-10-2023