At present, the "goods to person" picking system, which has high picking and storage efficiency, can significantly reduce labor and labor intensity simultaneously, is becoming a new industry mainstream and is increasingly applied to split picking operations. Especially with the rapid development of e-commerce and changes in consumption habits and patterns, the workload of dismantling and picking is increasing, and the regulations are also getting higher. The speed and accuracy of picking operations often determine the efficiency of order fulfillment and the quality of customer service. Therefore, how to accelerate picking speed is increasingly receiving attention from enterprises. In order to cope with the challenge of picking massive orders with multiple varieties, small batches, and multiple batches, inventory accuracy is low, delivery error rate is high, logistics efficiency during peak operations is low, and personnel scheduling during peak and trough periods is

difficult. In response to this series of warehousing challenges, Hebei Woke Metal Products Co., Ltd. has gained years of experience and mastered the collaborative collaboration of logistics systems. Through its own excellent technology and feasible solutions tailored to local conditions, it provides customers with different "goods to people" picking and warehousing solutions, which can effectively solve customer logistics difficulties.

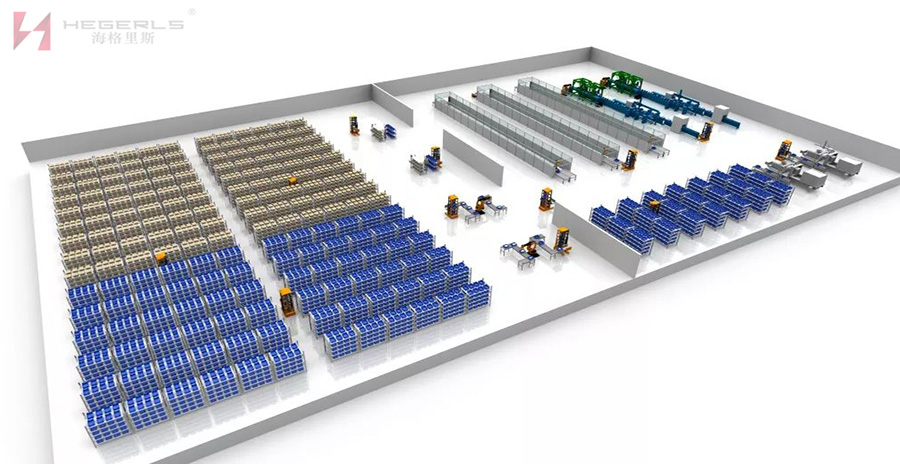

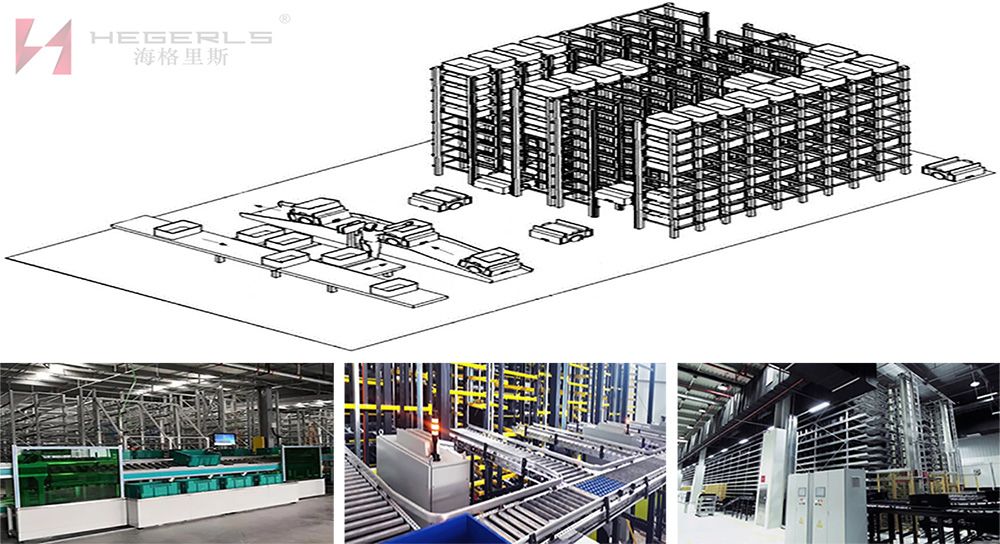

Hebei Woke Metal Products Co., Ltd. mentioned that the "goods to person" picking system is mainly composed of three parts: storage system, conveying system, and picking workstation. The storage system is the foundation, and its automation level determines the access capacity of the entire "goods to people" system. With the increasing number of disassembly and picking operations, material storage units have shifted from pallets to bins; The conveying system is responsible for automatically delivering materials to the picking staff, which needs to be matched with rapid access capabilities to simplify the conveying system and reduce costs; The picking workstation picks goods according to its order, and the picking staff utilizes a series of technologies such as electronic labels, RF, weighing, scanning, etc. to improve the picking speed and accuracy.

Hebei Woke's mainstream "goods to person" picking scheme

1) The "goods to person" picking system for four-way shuttle cars

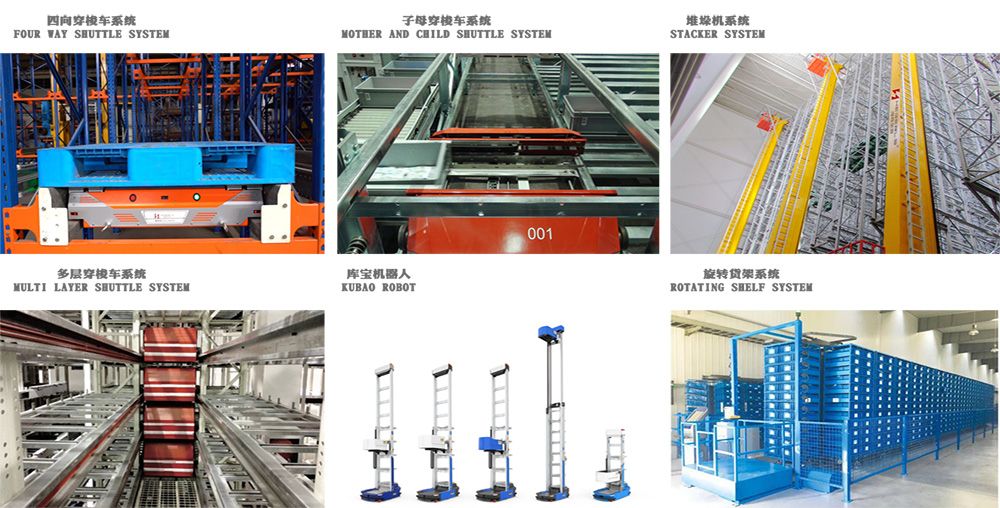

With the diversification and complexity of logistics center business types, four-way shuttle vehicles, as a new type of automated storage technology, have been increasingly used by many enterprises. Strictly speaking, the four-way shuttle system is an upgrade of the multi-layer shuttle system. It can travel in multiple directions, efficiently and flexibly operate across tunnels, and can fully utilize space. At the same time, the HEGERLS four-way shuttle system can also configure the number of cars according to the operating flow to reduce the increase of other equipment, and the combination of the HEGERLS four-way shuttle and the elevator is becoming increasingly flexible and efficient. The HEGERLS picking and selection four-way shuttle system launched by Hebei Woke allows

Hebei Woke's mainstream "goods to person" picking scheme

1) The "goods to person" picking system for four-way shuttle cars

With the diversification and complexity of logistics center business types, four-way shuttle vehicles, as a new type of automated storage technology, have been increasingly used by many enterprises. Strictly speaking, the four-way shuttle system is an upgrade of the multi-layer shuttle system. It can travel in multiple directions, efficiently and flexibly operate across tunnels, and can fully utilize space. At the same time, the HEGERLS four-way shuttle system can also configure the number of cars according to the operating flow to reduce the increase of other equipment, and the combination of the HEGERLS four-way shuttle and the elevator is becoming increasingly flexible and efficient. The HEGERLS picking and selection four-way shuttle system launched by Hebei Woke allows a HEGERLS four-way shuttle to pick multiple order lines for a single order within a work cycle, with a faster running speed of up to 5m/s; At the same time, with the help of precise positioning technology, it can save time in picking cargo locations, making them more convenient and efficient.

The HEGERLS four-way shuttle system can be linearly adjusted, which has a wider range of applications in industries such as e-commerce with high traffic and high storage capacity; Libraries are industries with low traffic and high shipping efficiency regulations; And manufacturing industry line logistics, and so on.

2) HEGERLS Light Stacker "Cargo to Person" Picking System

The HEGERLS lightweight stacker system is similar in structure to the AS/RS pallet type warehouse, but the storage unit for materials is the material box/cardboard box, which is also known as the material box type warehouse. Due to the dozens of different types of forks and pallets used in stackers, the HEGERLS four-way shuttle system has a wide range of adaptability and is also one of the important "goods to people" dismantling and picking solutions. The HEGERLS lightweight stacker system can operate at a maximum speed of 360m/min or above.

3) Multi layer shuttle vehicle "goods to person" picking system

With the immaturity of multi-layer shuttle system technology, the demand for disassembly and sorting operations has increased, and the difficulty of operations has increased. In recent years, the HEGERLS multi-layer shuttle system has been put into use by many domestic and foreign enterprises, making it the most high-speed storage and sorting solution. The HEGERLS multi-layer shuttle system has a very high operating efficiency, with a picking efficiency of 5-8 times that of traditional operation methods, generally reaching over 1000 times per hour. At the same time, it can also help enterprises save a lot of manpower investment costs. We can see that the multi-layer shuttle system is very suitable for industries with high demand for dismantling and picking, such as e-commerce.

4) HEGERLS Parent and Child Shuttle Picking System

The parent-child shuttle car system is mainly composed of shuttle cars, shuttle cars, aisle shelves, vertical elevators, conveying systems, walking tracks, automatic control systems, warehouse control systems, and warehouse management software. The working principle is that the shuttle mother car travels in the main aisle of the shelf. When it travels in the X direction and reaches a specific aisle, the shuttle car is released and continues to run in the X direction. The shuttle car runs in the Y direction, making it more flexible and efficient to use, thereby saving picking time and improving work speed.

The Mother and Child Shuttle System is a fully automated and dense storage system with low requirements for warehouse space, enabling fully automated storage with non continuous floor and multi area layouts. Hebei Woke HEGERLS needs to remind that the "goods to person" picking system of the parent shuttle is mainly used for storage and full box shipment picking.

5) HEGERLS rotating shelf "goods to person" picking system solution

The rotating shelf system is a mature cargo to person picking and warehousing solution launched by Hebei Woke, especially suitable for storing small items. With the technological innovation of HEGERLS rotary shelf system by Hebei Woke, its efficiency has also been greatly improved. The HEGERLS rotating shelf "goods to person" picking system can achieve a picking efficiency of 500 to 600 orders per hour at each picking workstation. At the same time, the HEGERLS rotating shelf "goods to person" picking system also has high-density storage function, which can achieve a series of sorting operations such as automatic inventory, automatic replenishment, automatic sorting cache, automatic storage, and so on.

6) Kubao robot "goods to person" picking system

The HEGERLS Kubao robot, also known as an intelligent warehousing robot, is highly automated and can greatly replace manual handling, picking, and other operations. At the same time, the system project implementation speed is fast and the delivery cycle is short. Not only that, HEGERLS Kubao robots also have a variety of styles to choose from, including the cardboard box picking robot HEGERLS A42N, the lift type picking robot HEGERLS A3, the double deep level feeding robot HEGERLS A42D, the telescopic lifting and lowering feeding robot HEGERLS A42T, the laser SLAM multi-layer feeding machine HEGERLS A42M SLAM, the multi-layer feeding robot HEGERLS A42, and the dynamic width adjustment box robot HEGERLS A42-FW. The Kubao robot "goods to person" picking system has functions such as intelligent picking and handling, autonomous navigation, active obstacle avoidance, and automatic charging. It has the characteristics of high stability and precision operations, and can replace repetitive, time-consuming, and heavy manual access and handling work. It achieves efficient and intelligent "goods to person" picking, greatly improving warehouse storage density and labor efficiency. Moreover, this system is highly flexible and easy to expand, Very suitable for scenarios with large SKU volumes, large product quantities, and multiple variety orders.

Based on the warehousing projects undertaken by Hebei Woke HEGERLS over the years, the "goods to people" system has become increasingly popular in the market due to its outstanding advantages in improving picking efficiency and reducing labor intensity. At the same time, different "goods to people" picking and warehousing solutions are increasingly being used in various industries, and there will be even broader development space in the future, especially in the e-commerce industry, which mainly focuses on dismantling and picking, The medical industry with higher sorting efficiency and accuracy, as well as the cold chain industry with special needs, will be applied on a larger scale. At the technical level, the "goods to people" picking system will have greater development potential in the direction of automation, intelligence, and principle, and will ultimately be replaced by robots to complete the picking work, thus achieving true intelligent and automatic picking.

Post time: Jun-19-2023