In today’s society, land is becoming more and more precious and scarce. How to place as many goods as possible in a limited space is a problem that many businesses consider. With the development of the times, the use of steel has been very common. The structure mainly made of steel is one of the most important types of building structures. Of course, with the development of economy and the urgent need of major enterprises, steel platform shelves have been put into use in large quantities. Then, there will be problems, such as whether the enterprise warehouse uses steel platform shelves or other storage shelves? What are the differences between this steel platform shelf and other shelves? What kind of maintenance is needed for daily use of steel platform shelves? Now, let the Hergels storage shelf manufacturer tell you the differences and safety maintenance between steel platform shelves and other shelves!

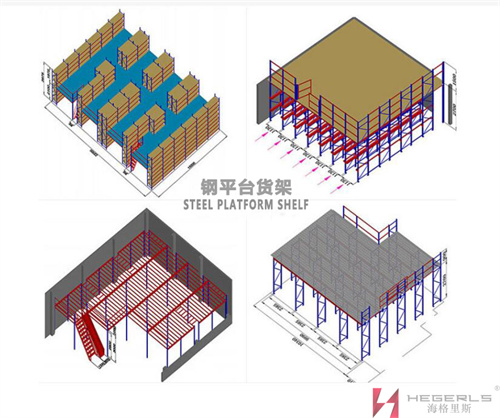

Steel platform shelves, also known as working platforms, are engineering structures made of steel, usually composed of beams, columns, plates and other components made of section steel and steel plates; All parts are connected with welds, screws or rivets. Modern steel platform shelves have various structures and functions. Its structural feature is a fully assembled structure with flexible design, which is widely used in modern storage. Steel structure platform usually builds a two-story or three-story fully assembled steel structure platform on the existing workshop (warehouse) site, changing the use space from one floor to two or three floors, so as to make full use of the space. The goods are transported to the second floor and the third floor by forklift or the goods elevator of the lifting platform, and then transported to the designated location by trolley or hydraulic pallet truck. Compared with the reinforced concrete platform, this platform has the advantages of fast construction, moderate cost, easy installation and disassembly, easy to use, and novel and beautiful structure. The distance between columns of this platform is usually within 4-6m, the height of the first floor is about 3M, and the height of the second and third floors is about 2.5m. The columns are usually made of square tubes or circular tubes, the main and auxiliary beams are usually made of H-shaped steel, the floor slab is usually made of cold-rolled rigid floor slab, patterned rigid floor slab, steel grating, and the floor load is usually less than 1000kg per square meter. This kind of platform can combine warehousing and management at the nearest distance. Upstairs or downstairs can be used as warehouse offices. Such systems are mostly used in third-party logistics, machinery manufacturing and other industries.

For this kind of shelf system, we must first carry out containerization and unitization, that is, package the goods and their weight and other characteristics, determine the type, specification and size of the pallet, as well as the single weight and stacking height (the single weight is generally within 2000kg), and then determine the span depth and layer spacing of the unit shelf according to the effective height and fork of the lower edge of the warehouse roof truss. The height of truck forks determines the height of shelves. The span of unit shelves is generally less than 4m, the depth is less than 5m, the height of shelves in high-rise warehouses is generally less than 12M, and the height of shelves in higher-rise warehouses is generally less than 30m (such warehouses are basically automated warehouses, and the total shelf height is composed of 12 columns). This kind of shelf system has high space utilization, flexible access, convenient computer management or control, and can basically meet the requirements of modern logistics system.

Steel platform shelves – details ensure safe use of shelves

Column – select round pipe or square pipe with strong bearing capacity;

Primary and secondary beams – select the most commonly used H-shaped steel in steel structures according to the bearing needs;

Floor – the floor has checkered steel plate, wood board, hollow steel plate or steel grating floor to choose from, which can meet the different needs of fire prevention, ventilation, lighting and so on.

Steel platform rack – auxiliary equipment

Ladders, slides – stairs are used for operators to walk to the second and third floors. The slide is used to slide goods from upstairs to downstairs, which greatly saves labor costs;

Lifting platform – used for the up and down transportation of goods between floors, economical and practical, with large bearing capacity and stable lifting;

Guardrail – guardrail is equipped at the place without wall to ensure that there will be no safety accidents for personnel and goods;

Wood plywood – the floor is paved with wood plywood, which is pressure resistant, durable, impact resistant, stable load, and saves space;

Steel gusset plate – the surface of steel gusset plate material is relatively bright, with good load, impact resistance and safety performance;

Galvanized steel plate – special galvanized checkered steel gusset plate for attic, which is scratch resistant, wear-resistant, slip proof and safety guarantee.

Influence of shelf thickness of steel platform on load bearing

The primary and secondary beams required for the fabrication of steel structure platform need to be strong, and the structural support of the whole platform depends on the primary and secondary beams, so it must be strong and strong in bearing capacity. There are many factors affecting the load-bearing of steel structure platform. It is mainly affected by the layout of members, such as: layout spacing and section size, service conditions, i.e. whether the use is accessible, indoor and outdoor, etc., regional load, i.e. providing the use area, affecting live load, seismic load, wind load, etc.

What are the differences between steel platform shelves and other shelves?

1) Integrated structure improves work efficiency

The storage and office can be designed as an integrated structure, so as to improve work efficiency. It can also be equipped with lighting equipment, fire-fighting equipment, walking stairs, cargo slides, elevators and other equipment.

2) Fully assembled structure has low cost and fast construction

The attic shelf fully considers humanized logistics, and has a fully assembled structure, which is convenient for installation and disassembly, and can be flexibly designed according to the actual site and cargo needs.

3) High load and large span

The main structure is made of I-steel and fixed with screws, with strong firmness. The span of the steel platform design is relatively large, which can place large pieces such as pallets, and can also be used for office use, as well as free shelves. It is very flexible and practical, and is widely used in all kinds of factory warehouses.

4) Realize centralized warehouse management and save positions

While saving positions, it improves the turnover rate of materials, facilitates the inventory of materials, doubles the labor cost of warehouse management, and comprehensively improves the efficiency and management level of enterprise asset management.

Safety maintenance of steel platform shelf

1) The steel platform shall be provided with a load limit plate.

2) The laydown point and upper tie point of the steel platform must be located on the building, and shall not be set on the scaffold and other construction facilities, and the support system shall not be connected with the scaffold.

3) The concrete beam and slab at the shelving point of the steel platform shall be embedded and connected with the bolts of the platform.

4) The horizontal included angle between the steel wire rope and the platform should be 45 ℃ to 60 ℃.

5) The tensile strength of the beams and columns of the tension joints on the upper part of the steel platform shall be checked to ensure the safety of the building and the platform.

6) The snap ring shall be used for the steel platform, and the hook shall not directly hook the platform ring.

7) When the steel platform is installed, the steel wire rope should be hung firmly with special hooks. When other methods are adopted, there should be no less than 3 buckles. The steel wire rope around the acute corner of the building should be lined with soft cushions, and the outer opening of the steel platform should be slightly higher than the inner side.

8) Fixed handrails must be set on the left and right sides of the steel platform, and dense safety nets must be hung.

Hagerls storage shelf manufacturer

Hagerls is a manufacturer engaged in the production of dense storage shelves, intelligent storage equipment and heavy storage shelves. It has more than 20 years of experience in customized storage production, various intelligent storage planning, and provides integrated services for shelves. Our main products are: Shuttle shelf, beam shelf, four-way shuttle shelf, attic shelf, steel platform shelf, drive in shelf, steel platform structure shelf, fluent shelf, gravity shelf, shelf shelf, narrow lane shelf, double depth shelf, etc. if you are interested in our storage shelves and storage equipment, please feel free to consult our company, We look forward to providing storage planning services to customers from all over the world!

Post time: Jul-27-2022