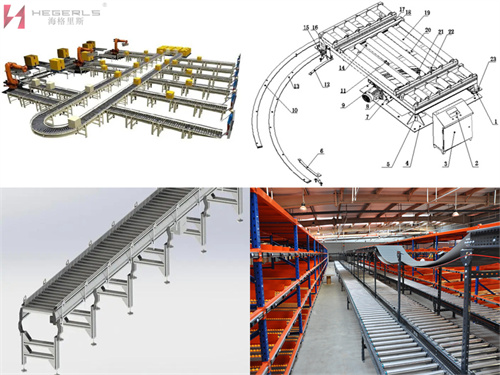

The diversion and confluence roller conveyor provides a new type of vertical diversion conveyor diversion roller, including: the diversion roller body, sleeve, shaft and belt, the sleeve is matched with the belt, the shaft equipment plays a rotating role between the sleeve and the shaft, the diversion roller body is provided with a positioning groove at a certain angle with the diversion roller body, the positioning groove is closely matched with the belt, and the angle of the positioning groove is generally 35 ° -45 °, Moreover, the positioning groove can make the belt cooperate with the positioning groove to avoid the drooping of the belt during the operation of the machine. Moreover, the positioning groove has a certain angle and the bearings of the transmission parts are positioned by using the inter axle and lock nut to facilitate the daily maintenance of the reversing roller and the belt by the maintenance personnel. Therefore, the reversing roller can ensure the long-term operation of the vertical shunting machine and improve the speed of shunting and sorting, At the same time, it is convenient for the staff to carry out daily maintenance of the reversing roll. Structural form of diversion and confluence roller conveyor: according to the driving mode, it can be divided into power roller conveyor and unpowered roller conveyor. According to the layout form, it can be divided into horizontal conveying roller conveyor, inclined conveying roller conveyor, turning roller conveyor, telescopic roller conveyor, etc. it can also be specially designed to meet the requirements of various customers. Now, we will introduce the hegris hegerls split sorting roller conveyor.

Hagerls split sorting roller conveyor

Heigris hegerls split sorting roller conveyor adopts multiple roller conveyors and other conveying equipment or special machines to form a complex logistics conveying system, which can meet various process requirements; The stacking roller can be used to realize the stacking and conveying of materials. Among them, the combined roller machine is suitable for the transportation of goods with a flat bottom, and can realize the characteristics of multi variety collinear shunt transportation; In order to ensure the smooth transportation of goods, at least three rollers must be in contact with the transported goods at any time point, and the soft bag packaging should be transported with pallets if necessary. Hercules Hegels split sorting roller conveyor has the characteristics of large conveying capacity, light transportation and convenient maintenance. It is widely used in conveyor types.

Structure of hegerls split sorting roller conveyor

The split sorting roller conveyor is composed of a frame, rollers, legs, etc., which is very suitable for heavy-duty conveying equipment. The split sorting roller conveyor can transport materials with a large single weight or bear a large impact load. It can also be made into assembly lines and storage and logistics transmission lines of various products. The driving forms include single chain wheel, double sprocket, o-belt, plane friction drive belt and so on. According to its structural form, it can also be divided into powered roller conveyor and unpowered roller conveyor. At the same time, it can also be specially designed according to customer requirements to meet the requirements of all kinds of customers. The split sorting roller conveyor is suitable for the transportation of various boxes, bags, pallets and other pieces of goods, bulk materials, small items or irregular items, but it needs to be placed on pallets or turnover boxes for transportation.

Heigris hegerls split sorting roller conveyor frame material

The split roller conveyor adopts carbon steel plastic spraying, and the general material is stainless steel or aluminum; Its driving forms are divided into two types: gear motor driving and electric roller driving; There are many kinds of drives, namely: single wheel, double wheel, o-belt, flat belt friction drive, belt drive, etc; Its high-speed mode is frequency control, stepless transmission, etc.

Specifications of hegerls split sorting roller conveyor

For the width conveyors within the range required by customers, they can be manufactured according to customers’ needs. The standard lines within the turning radius of rolling in turn are mostly 300, 600, 900, 1200mm, etc., or according to other special specifications of customers; The diameter of the straight roll is mostly 38, 50, 60, 76, 89mm, etc., and the roller is generally used. Hagerls will be designed according to the transportation object, size, speed, weight, etc.

Working principle of hegerls split sorting roller conveyor

The shunting roller conveyor realizes the function of shunting and merging goods through electric rollers. Each stacking section has an electric roller, and the electric cone roller is connected to a certain number of unpowered rollers through belts. With the help of the controller, the goods on the linear conveyor change direction under the state of zero pressure.

Characteristics of hegerls split sorting roller conveyor

1. Modular design, simple structure, easy assembly, convenient maintenance, only need to disassemble a few rollers can be completed.

2. The height of the outrigger is adjustable and has a wide range of application.

3. Electrostatic spraying on the surface, beautiful appearance.

4. Roller conveyors are easy to connect and transition, and can be used alone, or multiple roller lines and other conveying equipment or special machines can be used to form a complex logistics conveying system.

5. The stacking roller can be used to realize the stacking and conveying of materials.

6. Only suitable for conveying objects with flat bottom, not suitable for conveying objects with uneven bottom.

Application scope and application of hegerls split sorting roller conveyor

The split sorting roller conveyor is suitable for the transportation of various boxes, bags, pallets and other pieces of goods, such as bulk materials, small items or irregular items. Not only that, it can also transport materials with large single weight or bear large impact loads. It is generally used for the transportation of box type and flat bottom unit goods. It can also meet the separation and merging of transported goods when combined with single chain machine.

Hagerls is a domestic technology enterprise dedicated to the R & D, manufacturing, sales and service of intelligent robots, automatic logistics equipment and integrated logistics system solutions. From industrial robots, service robots and robot automation solutions to intelligent logistics and automated three-dimensional warehouses, the company has formed a leading technology at home and abroad A complete industrial chain integrating high-end equipment products and complete personalized industry solutions.

In the field of logistics, the company has strong R & D and design strength, and is committed to the integrated development of automatic warehouse, sorting system, conveying system, logistics equipment, etc., to provide customers with the most personalized services. At present, the company has reached cooperation with many high-end customers, and its business scope extends to industry, e-commerce, transportation, energy and many other industrial sectors. The company makes every effort to build a smart logistics business layout with scheme consulting and planning as the leader, high-quality logistics equipment development as the breakthrough, logistics information system as the soul, and the overall integration of logistics system as the leading.

With its rising brand image, increasing technical force and advanced service concept, the company has been involved in many industries, such as tires, medicine, express delivery, e-commerce, machinery, clothing, parks, education, military, industrial electrical appliances, food and beverage, etc. Hergels has provided customers with reliable, flexible and cost-effective solutions at home and abroad. Its services have helped customers save a lot of time and greatly improved the operation rate and structural upgrading of the industry. In the future, the company will continue to focus on innovation and lead change, and gradually develop into a “new business card” of the national automation industry, helping customers realize the informatization, intelligence and automation of manufacturing and logistics.

Post time: Jul-21-2022