Intelligent warehouses/warehousing run through all aspects of logistics, not limited to the automation of single operational processes such as storage, transportation, sorting, and handling. More importantly, they utilize technological means to achieve the automation and intelligence of the entire logistics supply chain process, effectively integrating various aspects of traditional automated warehousing logistics from multiple dimensions.

For example, in the construction of digital logistics warehousing, enterprises will extensively apply intelligent equipment and software such as automated three-dimensional warehouses, robots, laser scanners, RFID, MES, WMS, WCS, RCS, etc., integrating Internet of Things technology, computer technology, information technology, artificial intelligence technology, etc., to achieve the intelligent construction of factories.

Due to the fragmentation, personalization, diversification, and cyclical improvement of production orders in various enterprises in the current market, the technical level of intelligent warehouses (warehousing) is gradually improving, which is used to handle more complex storage, transportation, sorting, picking and other links. In response to this, Hebei Woke Metal Products Co., Ltd. (hereinafter referred to as “Hebei Woke”) has developed and formed a complete robot and intelligent production line based on the characteristics and needs of the current market and customer industry, and combined with the implementation experience of more than 100 projects at home and abroad, covering three major scenarios of access, transportation, and sorting, fully reflecting the comprehensive strength of technology, engineering, and industry experience. At the same time, it can cooperate with the intelligent logistics AI brain and the R&D capabilities of the entire line of software and hardware equipment to provide customers with end-to-end services that integrate consulting planning, software development, equipment manufacturing, project implementation, operation guidance, and after-sales service.

Saving the Black Technology of Intelligent Dense Storage

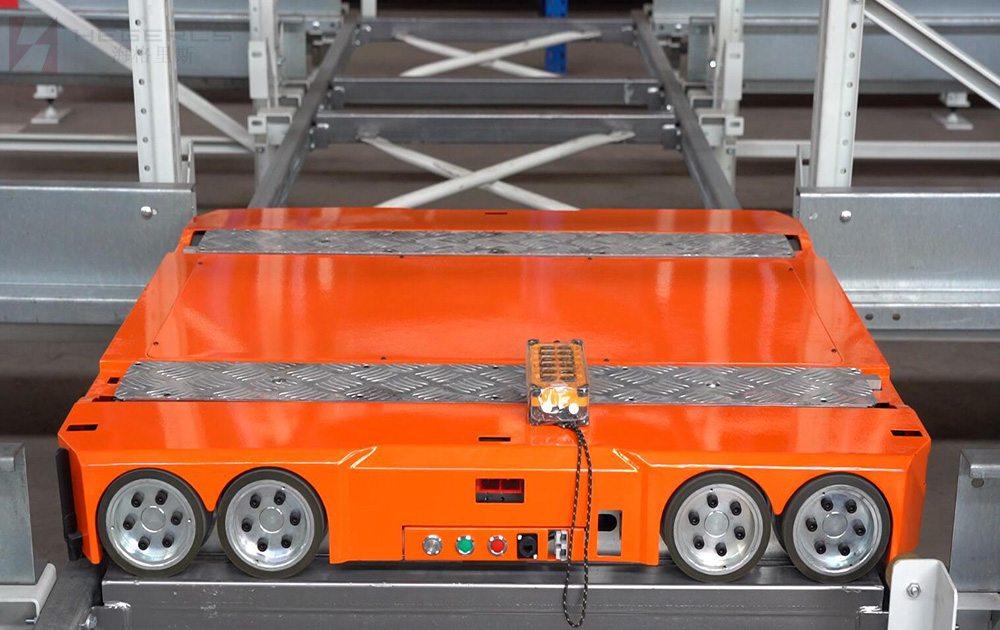

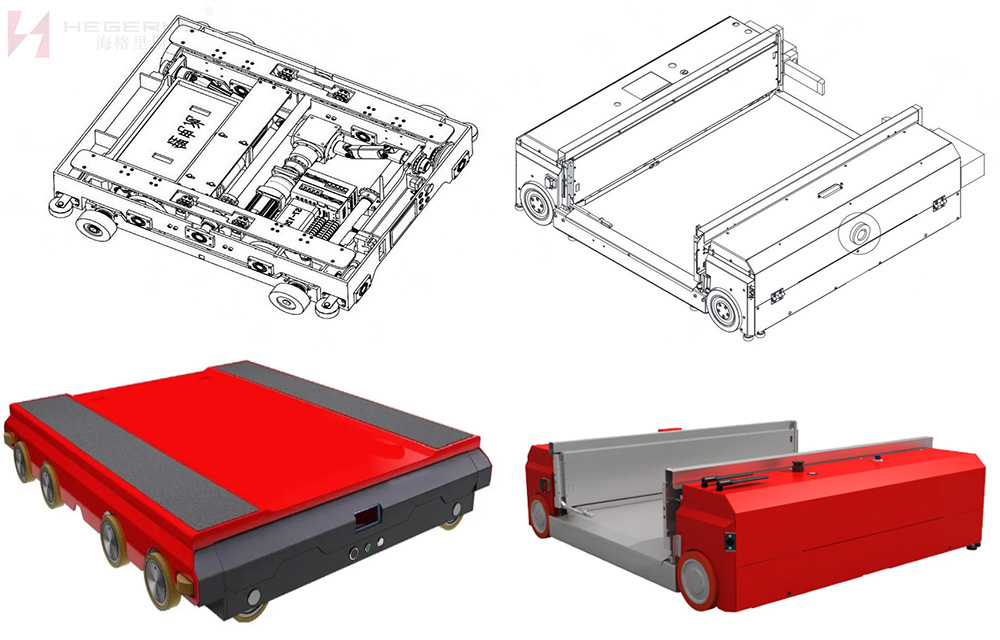

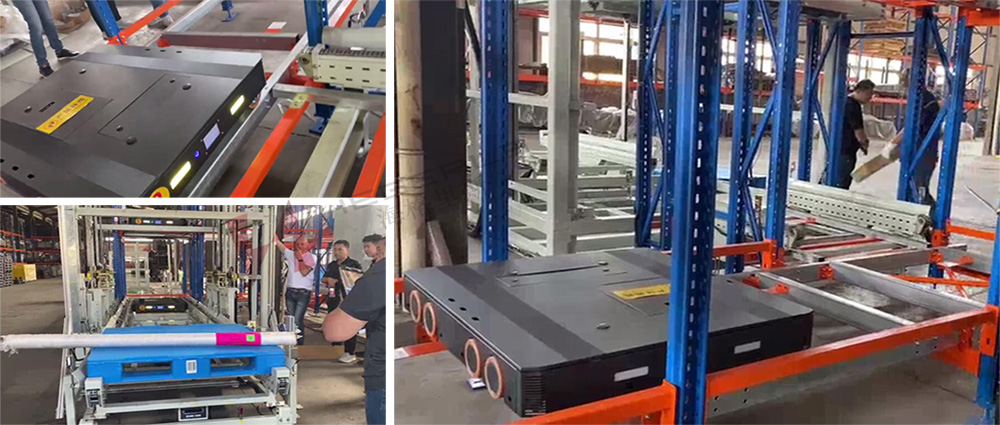

Hebei Woke’s independent brand Hegerls logistics robot matrix can meet various scenario applications such as access, handling, sorting, etc. As one of the earliest core products developed by Hebei Woke, the HEGERLS four-way shuttle car coincides with the trend of flexible and intelligent development in the logistics and warehousing industry. The access solution centered on shuttle cars perfectly solves the problems of dense storage and fast access of goods. A unique four-way shuttle robot solution based on the HEGERLS “shuttle car, elevator, shelf, etc.” module configuration. In a warehouse with ultra-high space utilization, the four-way shuttle car can access goods at high speed, and cooperate with the elevator system to be responsible for the inbound and outbound operations of goods. Moreover, by flexibly adjusting the operating tunnels of the shuttle car, the tunnels can be unbound from the hoist, breaking through the technical bottleneck of traditional multi-layer shuttle car systems. In other words, the four-way shuttle car system can configure equipment completely according to the operating flow, without wasting equipment capacity, and the coordination between the shuttle car and the hoist is also more flexible and flexible.

At the same time, the self-developed WMS and WCS systems can help enterprises establish a deep perception intelligent warehousing and logistics system, which can not only achieve the application of constant temperature warehouses, but also realize the smooth operation of four-way shuttle vehicles in cold storage/refrigerated areas (such as Hegerls access robots (material boxes/pallets) in ambient temperatures of -18 ℃ -+40 ℃. After perfect integration with WCS/WMS, multi vehicle collaborative operation can be achieved, meeting the needs of high-density and high flow warehousing, making inbound and outbound and picking operations more efficient.) The normal operation of storage, retrieval, and handling, intelligent management throughout the entire process, improves the efficiency of warehousing operations and the level of lean warehousing management, realizes automated storage and intelligent handling, reduces manual operation errors, saves labor costs, and enables efficient turnover of cold storage goods.

Intelligent warehousing and logistics is a long-distance race track. In the future, Hebei Woke will continue to invest in product research and development, providing customers with one-stop professional solutions from consulting, planning, design, product software to later operation guidance. In terms of after-sales service, we will also promise to respond promptly to customer needs within 24 hours. Secondly, we will also pay long-term attention to the usage of customer products to ensure the efficient operation of customer business. We will also upgrade the system according to customer business needs to better match user needs.

Post time: Feb-02-2024