As the leader of intelligent van type warehousing and logistics robots, hegerls is committed to providing efficient, intelligent, flexible and customized warehousing automation solutions through robotics and artificial intelligence algorithms, creating value for each factory and logistics warehouse. Hagerls focuses on the R & D and design of box storage robot system, and realizes the independent R & D coverage of core elements such as robot ontology, bottom positioning algorithm, control system, robot scheduling, intelligent storage management system, etc., which are sold at home and abroad. At the same time, its kubao system is the first box storage robot system developed and put into commercial use, which has been applied to 3PL, shoes and clothing, e-commerce, electronics, electricity, manufacturing, medical and other industries. Using kubao system, customers can realize the automatic transformation of the warehouse within a week, increase the storage density by 80%, and improve the working efficiency of workers by 3-4 times.

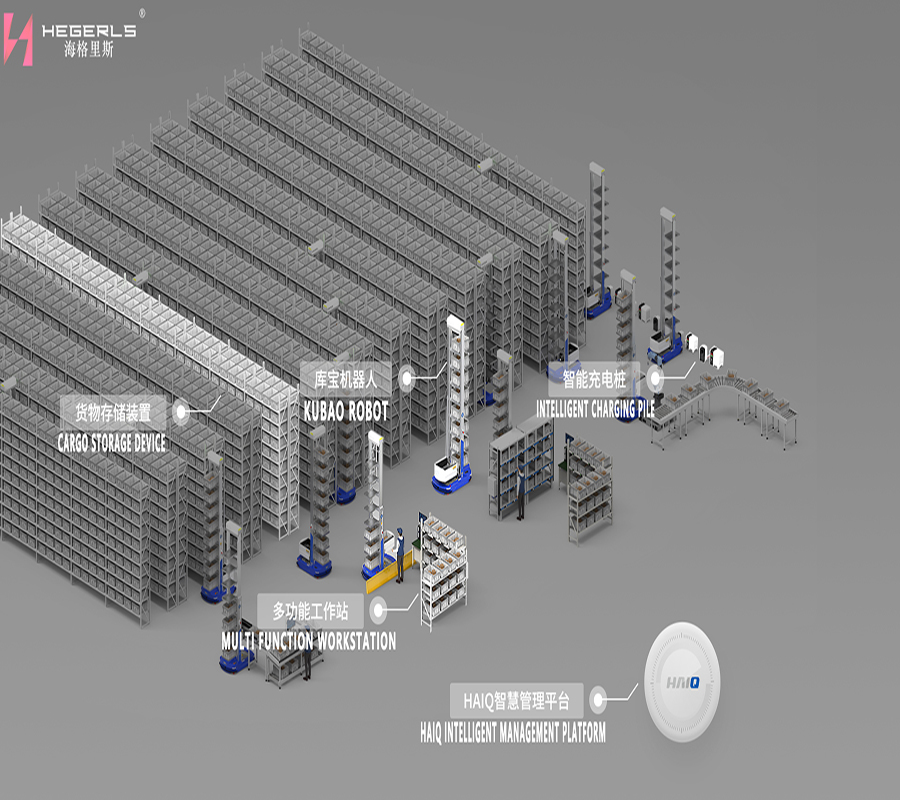

Hagerls intelligent warehousing logistics solution

Kubao system includes kubao robot, multi-function workstation, cargo storage device, intelligent charging station and haiq intelligent management platform. Intelligent scheduling based on haiq can realize external system access, scheduling of various logistics equipment, optimization of operation mode, visual management view and other functions, and provide customized intelligent solutions for customers according to the use scenarios and needs of the industry, covering a variety of business scenarios such as warehousing, logistics and manufacturing plants. It is suitable for e-commerce, 3PL, manufacturing, retail, footwear and clothing, electronics, medical and other industries.

Hegels box storage robot series

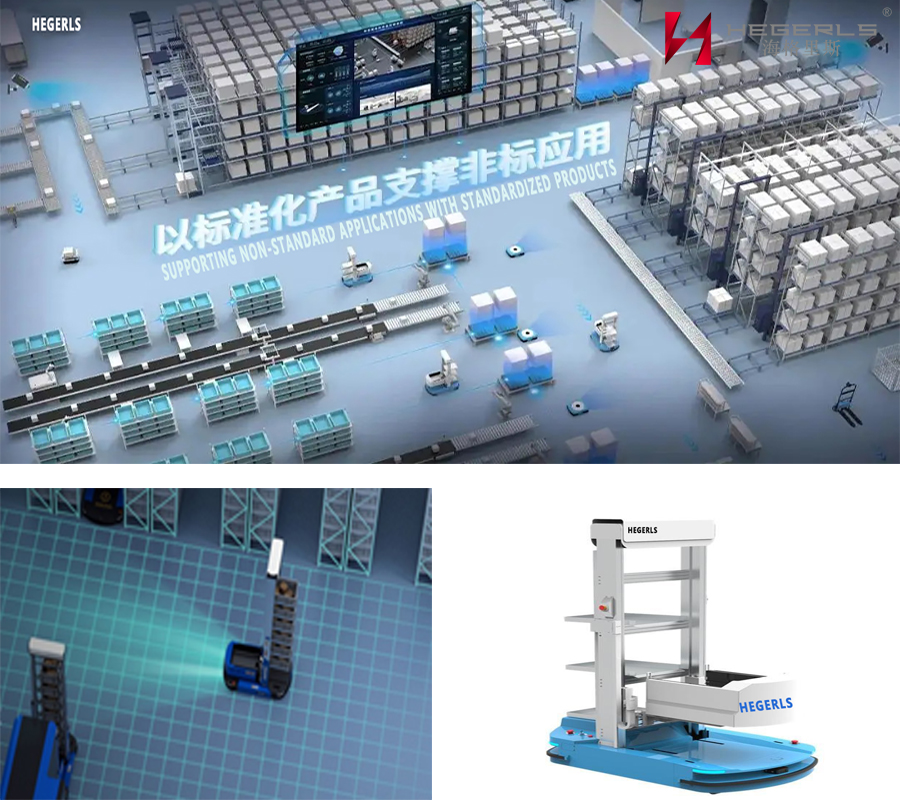

Kubao robot independently developed by hegerls is the first box type storage robot developed and realized commercial landing, which has opened up the subdivision fields of “container robot” and “container robot”. After continuous iteration and technological innovation, kubao’s product line has become increasingly rich. At present, the ACR system covers multiple product matrices such as herls A42 (multi-layer bin robot), herls a42d (double deep bin robot), herls a42n (carton sorting robot), herls a42t (telescopic lifting bin robot), herls A42 Slam (laser slam bin robot), which is suitable for multi scenario applications, solves different storage pain points, helps enterprises improve storage operation rate and reduce operating costs, Realize the upgrading of warehousing automation. This time we are going to introduce the laser slam multi-layer bin robot hegerls a42m slam.

Laser slam multi-layer bin robot hegerls a42m slam

Hergels’ independent innovation itself is that all commodities adopt the two-dimensional code navigation bar mode, mainly promoting the line side warehouse scene. Relying on the accumulation of Xiangong intelligence in slam technology navigation and operation, the laser double-layer material box intelligent robot launched by this company can realize laser slam navigation. It has built-in SRC core controller, has four functional highlights, integrates navigation, safety and multi-function, completes soft connection, accurate material taking and efficient transportation, and becomes the best partner of the line side warehouse of the processing workshop, enabling the intelligent manufacturing system.

Kubao hegerls a42m slam laser slam multi-layer bin robot is a box storage robot jointly developed by hegerls and seer. Hegerls a42m slam can realize laser slam autonomous navigation, and freely switch to QR code navigation, with higher security, practicality, maintainability and high environmental adaptability. As a new intelligent logistics handling equipment, hegerls a42m slam can realize intelligent walking in the storage space without the help of any track equipment. It has the functions of autonomous navigation, active obstacle avoidance, automatic charging, 3D recognition and so on, and realizes the mixed identification, picking, access, point-to-point handling of multi-size cartons / bins. Intelligent algorithm optimizes the efficiency of high and low cold and hot storage locations and cross region access and picking. Compared with the traditional AGV “shelf to person” solution, kubao robot picking granularity is smaller. According to the order requirements issued by the system, it really realizes the transformation from the traditional “people looking for goods” to an efficient and simple “goods to person” intelligent picking mode. Compared with the solutions of stacker and automatic three-dimensional warehouse, kubao robot system can realize efficient deployment, with low overall deployment cost and stronger flexibility; At the same time, hegerls a42m slam supports the docking of a variety of logistics equipment, including shelves, latent AGVs, robotic arms, multi-function workstations, etc. Flexible product design brings more operating space for customized solutions, comprehensively improves the efficiency of warehousing operations, optimizes the density of warehousing, and realizes the automation and intelligent transformation of the warehousing industry. Applicable scenario: it is suitable for warehousing applications in 3PL, shoes and clothing, e-commerce, electronics, electric power, manufacturing, medicine, retail and other industries, especially in the application environment of on-site equipment mobility and large traffic. Support customization of various sizes and depths.

Laser slam multi-layer bin robot hegerls a42m slam core advantages

Ultra precise pick and place

This laser slam multi-layer bin robot support system is connected, and it adopts visual AI and 2d/3d visual recognition to realize accurate material picking and placing, intelligent picking and efficient handling, one-time access and handling of multiple bins, support mixed picking of multi-size cartons / bins, and help ultra efficient operation.

Super flexible docking

Factory business is complex and diverse, and the demand for logistics equipment is also different. The laser slam multi-layer bin robot can flexibly connect a variety of equipment, including roller, shelf, latent AGV, artificial workstation and other operation platforms. It can get through the warehouse, line edge and production line, and can be taken and placed freely. As you want, it can be connected infinitely, with a wider range of application scenarios.

Superhuman design

This laser slam multi-layer material box robot adopts superhuman design, realizes free lifting of 0.4m ~ 1.86M, adapts to manual operation mode, flexibly matches various operation heights, seamlessly accesses scheduling and storage systems, deeply optimizes business with intelligent algorithm, creates comfortable operation experience, and human-computer interaction is more friendly.

Ultra flexible deployment

Cope with the changing working environment? Slam navigation helps the robot to adapt to the flexible change of work location, without two-dimensional code navigation, autonomous navigation, free switching two-dimensional code navigation, simple deployment, breaking through the limitations of traditional assembly lines, realizing discrete manufacturing, flexible enabling intelligent manufacturing.

Super safe navigation

The SRC controller developed by Xiangong intelligent is built into the laser slam multi-layer bin robot, which provides the robot with basic functions such as map construction, positioning, navigation, multi machine scheduling, automatic charging, 3D obstacle avoidance and other functions, so as to achieve ultra safe navigation and protect the safety of staff. It is suitable for complex man-machine mixed field environment, and is more intelligent and efficient.

Focus on core technology and enrich the product service market

Hagerls focuses on the solution of bin storage robot. As a core part of the supply chain, warehousing needs to be upgraded iteratively from traditional manual warehousing to mechanized warehousing, automated warehousing and flexible warehousing in order to meet the efficiency and flexibility of the supply chain. Hegris Hegels uses artificial intelligence technology and robot technology to help customers provide flexible, efficient, intelligent and customized solutions, and finally help customers create value in warehouses and factories. Hagerls takes kubao robot as its core product to help customers provide flexible and efficient solutions.

Post time: Jul-05-2022