With the rapid development of enterprise scale, many enterprises have increased their variety of materials and complex business operations. The traditional warehouse management model is more extensive and difficult to achieve precise management. With the continuous increase in labor and land costs, the transformation of warehouse automation and intelligence has become an inevitable trend. With the rapid development of modern manufacturing and the transformation of production models, automated three-dimensional warehouses have become important facilities for enterprises due to their low floor area, high operational efficiency, and intelligence. At present, according to the needs of enterprises and the equipment used, multiple robots and solutions have been launched in the market. Among them, the four-way shuttle truck and stacker crane three-dimensional warehouses, as the mainstream storage modes of pallet type automated three-dimensional warehouses, have received widespread attention.

The manufacturing accuracy and installation accuracy of three-dimensional warehouse shelves are relatively high, with strict requirements for equipment and manufacturing processes. Hebei Woke Metal Products Co., Ltd. has a well-known manufacturer specializing in related equipment technology, and has invested a large amount of funds and technical support in the research and development and upgrading of related intelligent equipment every year. The company has excellent equipment, multiple high-precision profile automatic cold bending production lines, various types of processing equipment, fully automatic suspension spraying lines, and pre-treatment cleaning and shot blasting systems, which can provide epoxy resin, polyester resin, or metal powder Anti static spraying, automatic welding, Hebei Woke Xingtai Factory has an automated production line, intelligent management, finite element simulation analysis, combined with our company's (Hebei Woke Metal Products Co., Ltd., self owned brand: HEGERLS) nearly 20 years of experience in automated vertical warehouse shelf construction, dedicated to creating an unparalleled automated three-dimensional warehouse shelf system for customers. At present, Hebei Woke HEGERLS has occupied a certain position

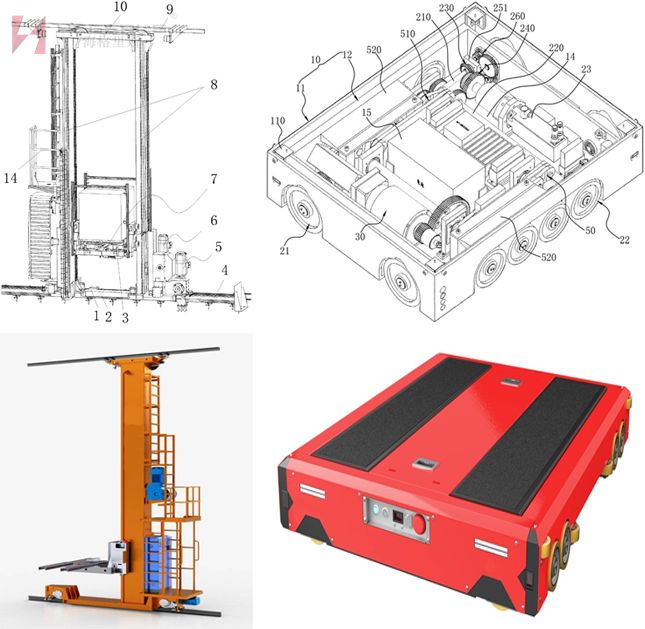

both domestically and internationally, and has been trusted by corporate customers from dozens of countries such as the United States, Italy, the United Arab Emirates, and Thailand. Its independently designed, developed, and produced intelligent shuttle cars, multi-layer shuttle cars, parent-child shuttle cars, four-way shuttle cars, and tunnel stackers have become the designated brand of automated three-dimensional warehouse equipment for many enterprises.

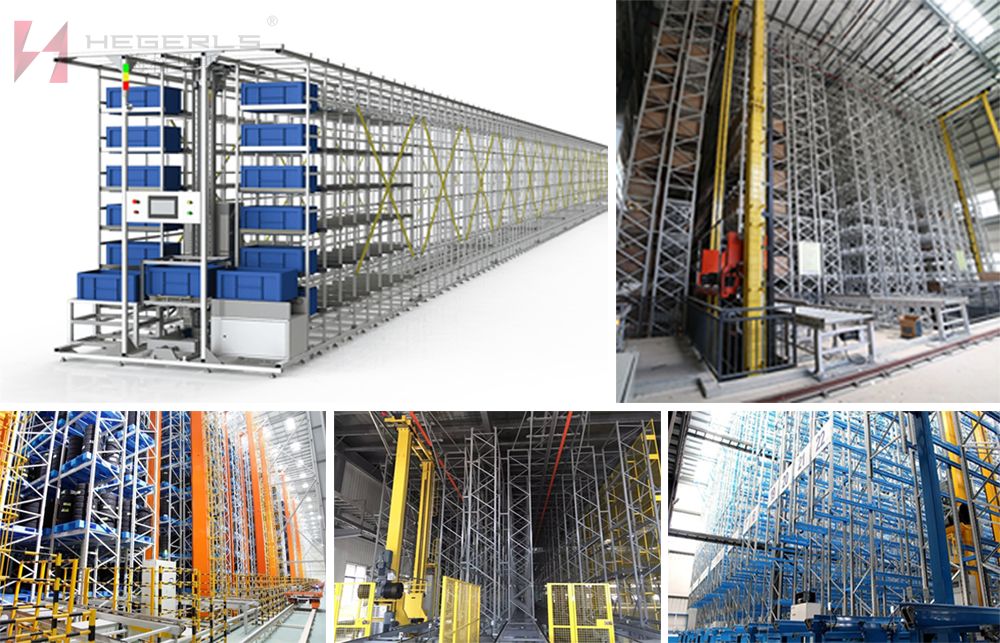

Hagrid HEGERLS Stacking Machine Stereo Warehouse (AS/RS)

Stacker is the most important operating machinery in automated three-dimensional warehouses. It is a specialized robotic arm developed with the emergence of three-dimensional warehouses. It is composed of narrow channel high-rise shelves, stacker cranes, conveyor line platforms, and computer control systems. Through the stacker crane, it shuttles back and forth in the alleys of the high-rise shelf three-dimensional warehouse, storing goods located at the entrance of the alleyway into the shelves or taking out goods from the shelves to transport them to the roadway entrance, Complete

the inbound and outbound operations of goods. At the same time, under the scheduling of warehouse management software (WMS/WCS), automated entry and exit operations can be achieved through tunnel stackers. Depending on the type of storage and efficiency requirements, different models such as single extension stacker, double extension stacker, dual station stacker, and turning stacker can be selected. Stacker cranes generally operate on fixed tracks and cannot change their route. One stacker crane is responsible for a single lane, where single machine operations are carried out. In order to achieve the three-dimensional storage and retrieval of goods, it is necessary to coordinate the work of walking, lifting, and forking. The system operates stably and is easy to maintain. Stacker three-dimensional warehouses are widely used in industries such as tobacco, medical, and e-commerce due to their advantages of high-speed, accurate, stable, and traceable data.

Hebei Woke recommends three different solutions for stacker three-dimensional warehouses

In fact, three different storage solutions can be divided based on the number of shelves on both sides of the roadway for enterprise users to choose from when putting into use the Hagrid HEGERLS stacker three-dimensional warehouse.

1) When there is only one row of shelves (single depth shelves) on both sides of the HEGERLS stacker warehouse roadway, such warehouse shelves are the most common. And this warehousing solution is more fully utilized in terms of shelf height, and goods can be directly picked up without moving to the warehouse, which is also the highest efficiency.

2) When there are two rows of shelves (double deep shelves) on both sides of the HEGERLS stacker three-dimensional warehouse roadway. Under this warehousing solution, when the current cargo in the back row is inconsistent, there should be no

cargo obstruction in the front row when the stacker picks up the cargo in the back row; When there are currently goods in the queue, the stacker needs to move the goods in the front row to the appropriate position before forking the goods in the back row. Moving the warehouse will affect the stacker system's inbound and outbound capacity to a certain extent, but the number of storage spaces can significantly increase compared to single deep shelves. The use of a dual deep shelf solution is suitable for scenarios where there is a low requirement for inbound and outbound efficiency and a high number of storage locations, or where there are fewer SKUs and more storage locations. Under the same storage location requirements, it can effectively save the number of stackers and save costs.

3) One side of the three-dimensional warehouse lane of the stacker is a single depth rack, and the other side is a double depth rack. Under this layout, there is a combination of single depth shelves and double depth shelves. The single depth shelf side can avoid storage relocation, while the double depth shelf side can fully increase storage capacity.

Of course, the final form of warehousing solution to be adopted still needs to be reasonably planned based on the efficiency of inbound and outbound storage, storage rate, SKU number, etc.

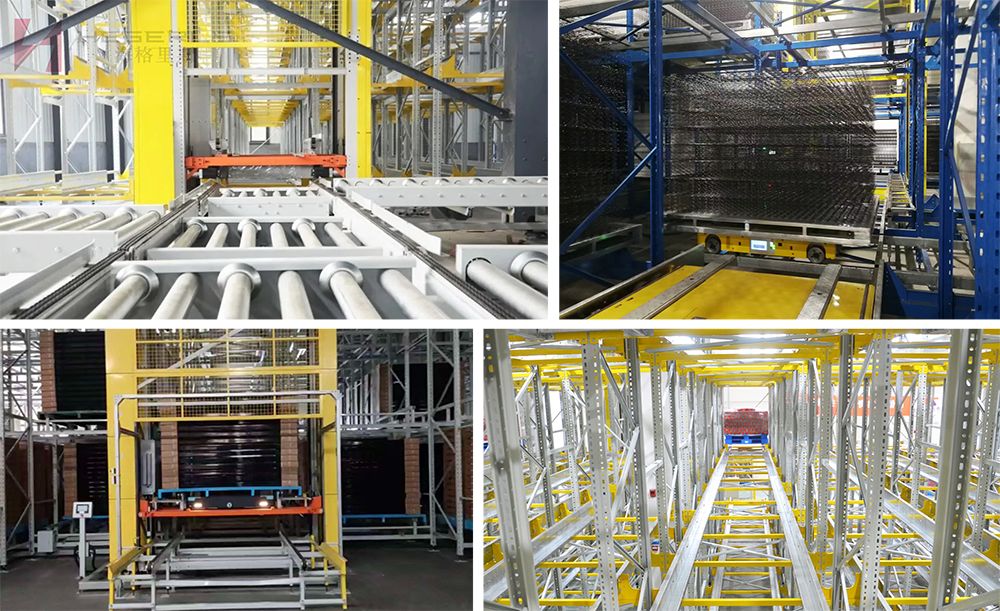

HEGERLS four-way shuttle car three-dimensional library

As is well known, the four-way shuttle three-dimensional warehouse is a new intelligent warehousing system that integrates multiple functions such as automatic stacking, automatic handling, and unmanned guidance. With the rapid development of warehousing logistics and e-commerce industries, it has been widely applied. The four-way shuttle vehicle three-dimensional warehouse has the characteristics of large storage capacity improvement, high operational efficiency, rich application scenarios, and high scalability. It can help enterprises achieve process automation, process visualization, and integration of online and offline. The use of three-dimensional warehouses can effectively reduce enterprise logistics costs, improve logistics efficiency, and greatly improve production efficiency.

The automated three-dimensional warehouse with four-way shuttle cars is currently a high-tech intelligent warehousing system solution, mainly composed of dense shelves, four-way shuttle cars, elevators, conveyor lines, WMS, WCS, and RCS. The three-dimensional warehouse shelves have standard cargo space and are responsible for storing goods. The height of the three-dimensional shelves can reach several tens of meters, and most of them use a crossbeam type shelf structure. By flexibly driving the shuttle car in front, back, left, and right of the shelves, goods can be picked and transported. It has two working modes: fully automatic and semi-automatic. Maximize storage space. By integrating WMS and WCS system software with enterprise ERP, SAP, MES and other management system software, the principle of first in, first out of goods can be maintained, eliminating the chaos and low efficiency of human operations. The four-way vehicle three-dimensional warehouse has the advantages of flexibility, flexibility, and intelligent scheduling. It can reach any position in the warehouse and continue to complete work through the WCS system, without being limited by space.

The four-way shuttle car three-dimensional warehouse has more advantages in terms of safety and stability, suitable for both low flow and high-density storage, as well as high flow and high-density storage and sorting. Compared to traditional stacker crane three-dimensional warehouses, each cargo needs to be reserved for storage and operation space. The four-way shuttle car three-dimensional warehouse can minimize such non storage space, achieve the highest density of storage, and increase the storage capacity by more than 20% to meet the diverse needs of customers. The product is highly intelligent in design, capable of automatic handling and transportation, automatic storage and retrieval of goods, and automatic lane changing and layer changing. For large three-dimensional warehouse systems, the four-way shuttle has a high cost-effectiveness, which can be improved by increasing the number of small cars and improving the level of entry and exit. Regardless of the small or large outbound volume, the four-way shuttle truck three-dimensional warehouse solution is very suitable.

Post time: Jun-27-2023