Vertical rotary containers are also called three-dimensional rotary warehouses, automatic warehousing machines, three-dimensional vertical containers, vertical lifting containers, also known as rotary warehouses and CNC rotary warehouses. Vertical carousel is the main equipment of modern warehousing, which realizes automatic operation of the warehouse and improves management. Vertical rotary container is an automatic storage and item management equipment, and a high-density dynamic intelligent vertical rotary storage system. Intelligent vertical revolving container is a modern storage system that can be widely used in intelligent manufacturing, intelligent medical, intelligent government and other industries. The system is composed of two parts, one is a vertical rotating container, and the other is a PC workstation. The software module is selected based on the workflow. The inventory management software connected with the upstream and downstream software management systems can be realized at the same time. The intelligent control system provides fast and accurate access to goods.

About haigris shelf manufacturer

Haigris shelf manufacturer is a professional company integrating the development, design, production, system integration, consulting and planning of warehousing and logistics equipment and intelligent industrial equipment. The company is committed to the planning, design, integration and promotion of enterprise intelligent warehousing systems, and provides enterprises with the latest warehousing management concepts, space implementation and solutions. Over the years, the company has been continuously tracking the latest development of warehousing and logistics technology in the world. With a brand-new modern logistics concept and rich industry experience, according to the different requirements and actual needs of the market and customers, the company provides users with warehousing and logistics system solutions suitable for different needs. We also use exquisite manufacturing technology and advanced production equipment to provide advanced, practical, efficient, safe and diversified warehousing and logistics products and work station appliances for the production and processing, circulation and transfer, warehousing, transportation, loading and unloading, distribution and other links of customer construction projects, which are highly praised by users. Our products are mainly used in aviation, high-end manufacturing, food, automobile, machinery, home appliances, light industry and electronics, medical, chemical and commercial logistics industries. Based on many years of industry experience, the company divides its products into three categories: intelligent storage containers, storage shelves and station appliances, providing comprehensive and tailor-made services for factories. The following is the vertical revolving container produced by the Hagrid shelf manufacturer.

Haigris vertical revolving container

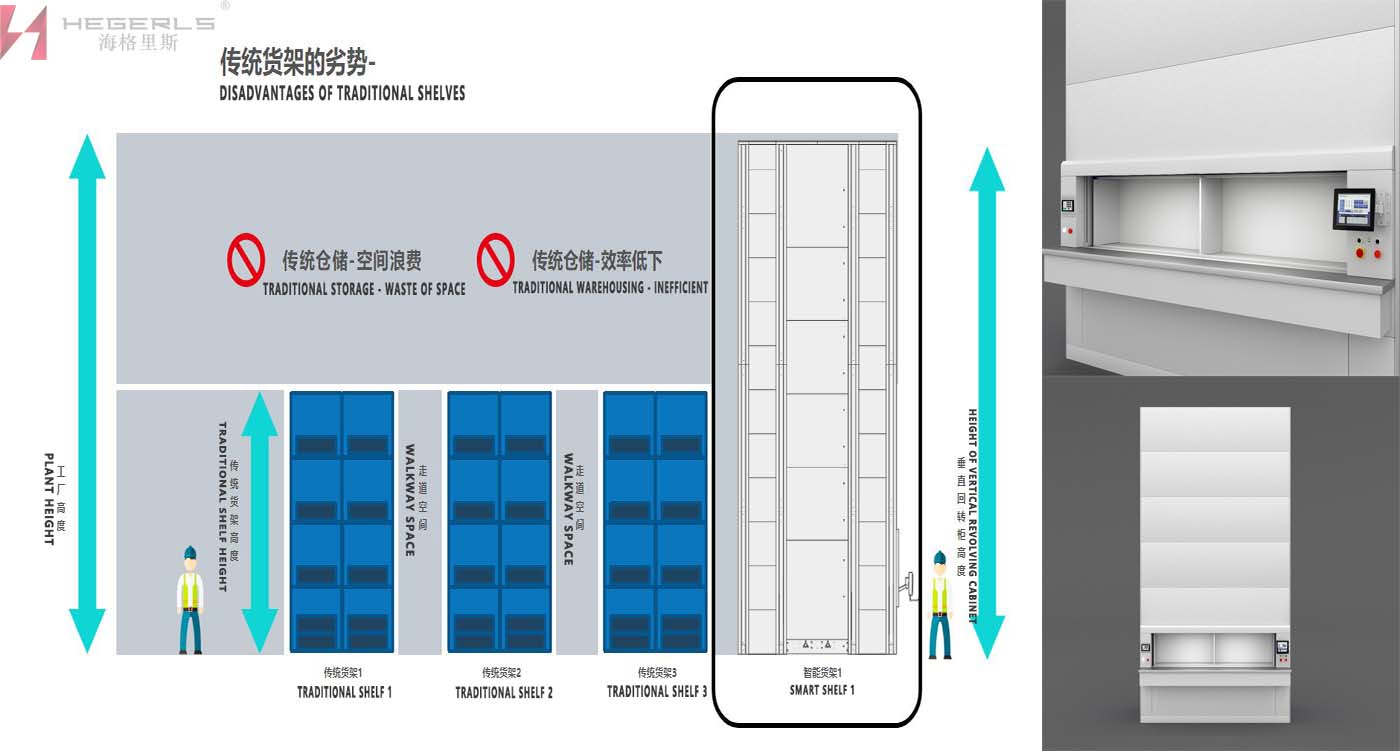

The vertical revolving container system is based on the principle of goods arriving at people. It makes full use of the ceiling height, occupies small floor area and realizes large storage capacity. At the same time, the internal storage unit of the equipment is provided with a separation layer design, which can be easily adjusted according to the height of the stored items, high-density storage, and increased storage capacity. In addition, closed storage provides protection against dust, dirt and moisture. According to the needs of surgery, we always pick up the items we need to provide fast and accurate access.

PC workstation

The workstation is equipped with a PPG software system, which contains a variety of functional modules, such as article management, warehouse management, space management, user management and order processing functions. In addition to the functions of reporting, barcode inspection and manual operation, the software is also attached with use management accessories, dynamic inbound and outbound lists, and various forms of material transportation records. It is not only the clean operating room that manages the number of surgical articles in the library, At the same time, the management of surgical items can be optimized according to needs.

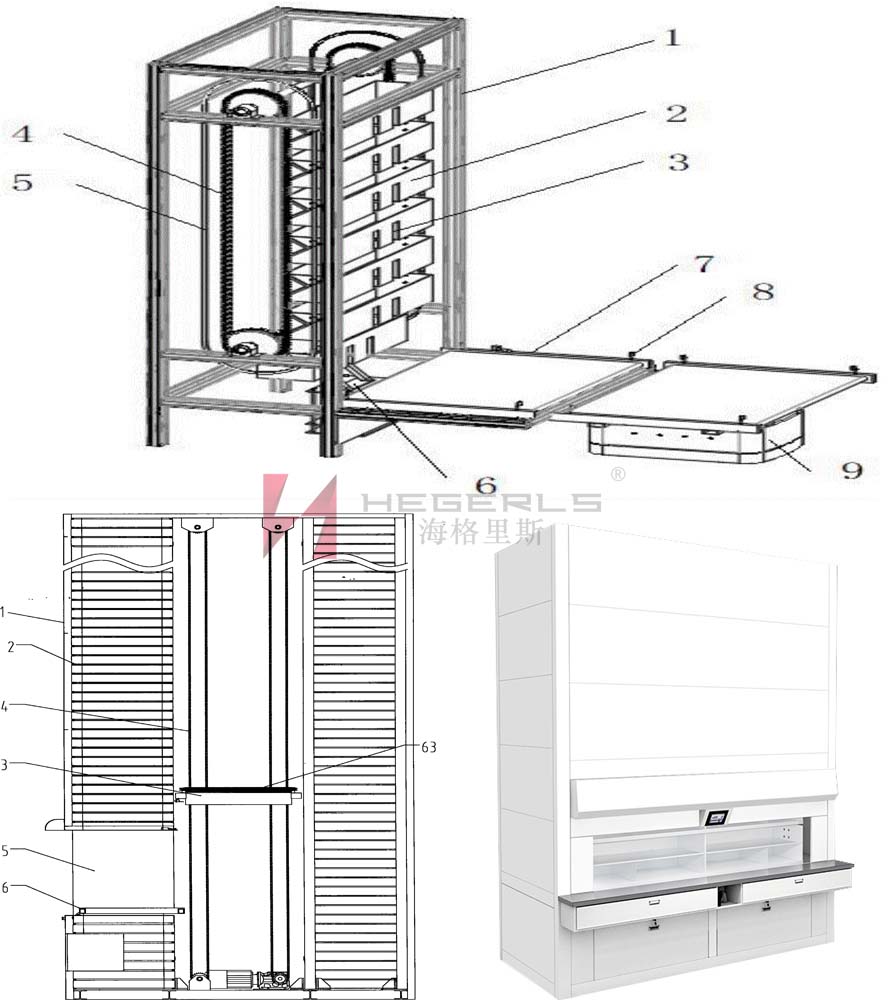

Working principle of vertical revolving container

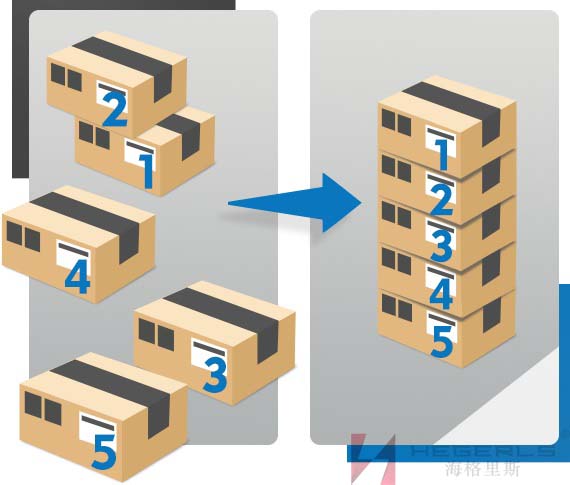

The vertical circulation container takes the plastic box as the storage unit, and drives the plastic box to rotate through the chain drive. When the container is running, the system adopts an optimal algorithm to automatically select the shortest path, so that the materials can reach the operators quickly. It is very suitable for placing near the production area to store spare parts, production tools and CNC tools.

Application scope

It is mainly used to store tools, knives, industrial parts and spare parts, electronic components, cigarette machine spare parts, cigarette grassland, auxiliary materials, medical supplies, appliances, as well as important documents, data, optical discs, magnetic media, etc. it can be widely used in aerospace, tobacco, machinery, petrochemical, medical, electronics, archives, docks, railways, automobiles and other industries.

Features and advantages of vertical revolving container

Space – modular structure & high frequency access, automatic height measurement, reasonable arrangement of storage space, increase storage capacity with compact floor area, and save 60% to 85% of the required ground space.

Query efficiency – the efficiency is increased to 100% – 200%, and the space of the automatic cargo space is optimized;

Accuracy – the shelves can be rotated forward or backward. Based on the operation of the chain bucket elevator, the goods can be sent to the required position through the shortest distance, and the accuracy of handling inventory products is as high as 99%.

Control – network management can be realized to improve response time; Accurate inventory and information control to meet the needs of efficient and safe storage.

Ergonomics – with mechanical transmission as the main principle, box and bucket as the storage unit and address recognition unit, it intelligently selects the best path and delivers the stored goods to the operator at the fastest speed. It is especially suitable for frequently accessed goods and handles the determined goods in an ergonomic way.

Security – multi level password management function; The equipment is fully enclosed, which can effectively avoid the invasion of dust and sunlight;

Operation mode – first in first out function; Single machine manual, automatic and online automatic operation modes; The serial and modular design provides users with more choices, shortens the supply cycle, and provides customized special cabinet types according to user needs;

Structure – compact structure, precise control, suitable for storing items with large differences in size and specifications, and low power consumption; The cabinet is stronger and has stronger bearing capacity;

Access – it can cross floors, and set pick-up ports on each floor as required to make access more convenient and fast; The operation is more stable, faster and safer.

Functional advantages of vertical revolving container

Modular design – it can quickly adjust the height to meet various needs, and easily cope with the inconvenience caused by location change in the future.

Toothed belt conveyor ensures faster operation and more timely access, low noise and long service life.

Multi capacity pallets – pallets with different loads can be used in a unit module, which ensures the flexibility and pertinence of inventory.

Plug and play software – the operating software used by haggis vertical rotary container is suitable for WMS, ERP and other management software, which is plug and play.

Intelligent positioning – intelligently trace the height of goods stored, find the most ideal memory location in the equipment, automatically store goods, and make full use of space.

Automatic cabin door – it blocks noise and ensures the safety of operators and cargo.

Flexible tray transfer – the height of the transfer tray can be adjusted according to the height of the operator, which is convenient for work. One access window supports the transfer of two trays, which is convenient and fast.

Built in weight monitoring system – Pallet monitoring and unit load effectively prevent pallet overload or unit overload.

Hegerls has a rich category of vertical revolving containers, and can customize the specifications as required, namely:

Light intelligent vertical rotation container: the maximum load of a single bucket is 250 kg, and the height of the workbench is 900; It is used to store light articles such as electric energy appliances, electronic components and medical appliances of the power grid;

Medium sized intelligent vertical rotary container: the maximum load of a single bucket is 350 kg, and the height of the workbench is 900; Used for storing spare parts, standard parts and auxiliary materials in industrial and mining enterprises;

Heavy intelligent vertical rotary container: the maximum load of a single bucket is 500 kg, and the height of the workbench is 900; It is used to store heavy items such as finished products, tool sets, molds and precious raw materials.

Why do many enterprises choose vertical revolving containers for use?

1) Rows of shelves are hung at both ends inside the vertical revolving container, and the shelves can rotate forward or reverse.

2) The vertical rotary container adopts the working principle of picking type selection, which occupies a small space and stores many varieties, up to about 1000 kinds.

3) The small cells of the vertical revolving container can be removed, so that goods of various sizes can be stored flexibly.

4) The picking table is supported on the front and back of the vertical rotary container, which can be used to conveniently arrange the warehousing operation, and can also be controlled by computer to form a linkage system to send the cargo layers required by the instructions to the required positions through the shortest distance.

5) The vertical revolving container is mainly used for multi type / high frequency goods.

Post time: Sep-07-2022