The development of logistics involves various fields of industry and commerce, covering the entire process of raw materials and finished product production from the starting point to the destination. In indoor logistics operations, it includes operations such as receiving, sending, storing, and picking. In recent years, due to the increase in labor costs, the difficulty of obtaining basic labor has continuously increased, and automation and intelligence have gradually become an indispensable part of enterprise development; Accuracy, precision, timeliness, efficiency, cost-effectiveness, and other key elements of enterprise competition are gradually forming.

Faced with the fierce market situation, Hebei Woke has always maintained a highly sensitive sense of smell, exploring every innovative touchpoint: researching data mining, image processing, intelligent optimization algorithms, expanding the application scope and collaborative scale of intelligent logistics equipment systems, significantly improving operational efficiency, providing highly intelligent, flexible, reliable, and cost-effective warehousing solutions, etc. It has always adhered to the output of high-quality logistics robots, high-performance logistics software systems, and high standard and high-quality planning and design solutions, and is gradually achieving comprehensive advancement of technical strength and product quality.

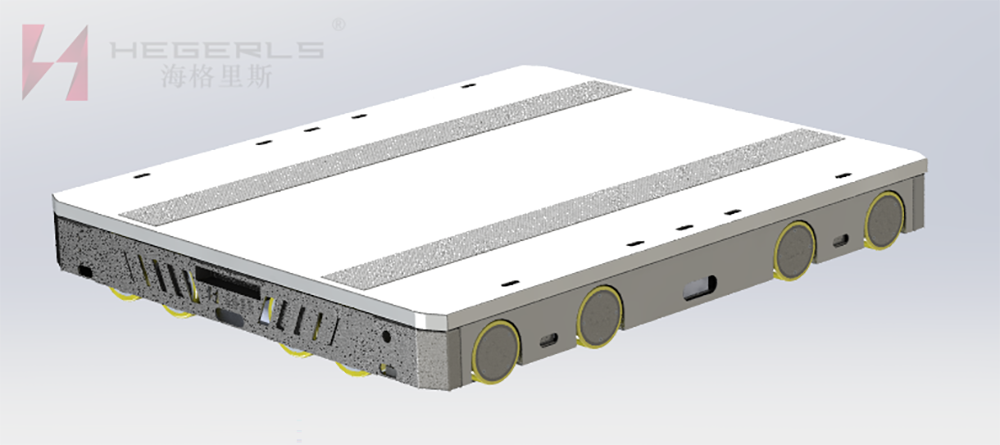

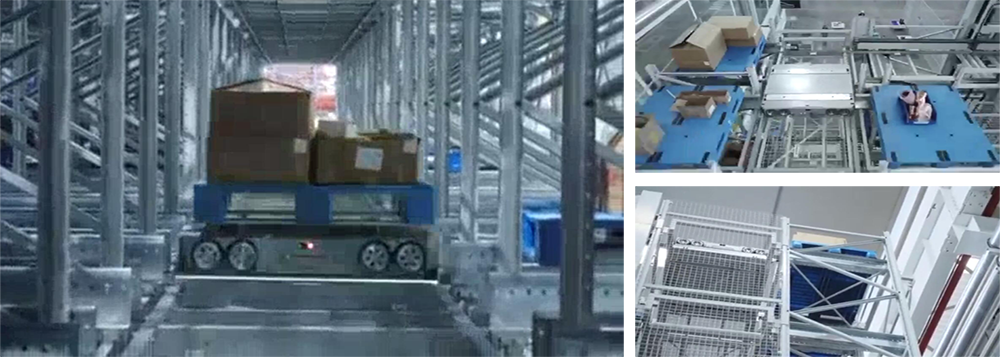

Since its establishment in 1996, Hebei Woke has focused on the research and development, production, and development of four-way shuttle technology. With years of logistics experience and technical accumulation, it has independently developed core logistics equipment such as HEGERLS four-way/two-way shuttle, multi-layer shuttle, stacker crane, high-speed elevator, AGV, conveyor sorting system, etc., providing customers with consulting and planning, software development, equipment manufacturing, project implementation, and more An end-to-end service that integrates operational coaching and after-sales service.

Along the way, Hebei Woke has achieved its first stage goal, not only possessing full scene logistics robots and intelligent equipment covering access, handling, and conveying sorting, but also implementing over a hundred logistics projects in multiple industry fields and gradually gaining market recognition.

The HEGERLS four-way shuttle system, in conjunction with elevators, conveyor lines, and “goods to people” picking workstations, can achieve an intelligent warehousing solution for “goods to people”, and is perfectly integrated with logistics information management systems to achieve automated access, handling, picking, and other functions. Shuttle cars can flexibly achieve cross tunnel operations, with equipment being backup to each other, providing great flexibility and diversity. At the same time, it solves the contradiction between stock, flow, flexibility for future expansion, and cost-effectiveness. Its comprehensive ability and universality are the strongest, and it has great application space.

Hebei Woke’s New Generation Robot Scheduling and Control System

The trend of unmanned operation in the future is irreversible. Although it is still in the transitional stage, the ultimate goal of WMS is to command all robots and equipment in the entire warehouse to complete operations. The Hebei Woke Robot Scheduling and Control System is precisely such a software system that can manage various types of robot equipment. Since its establishment, Hebei Woke has accumulated relevant knowledge and developed its unique robot scheduling and control system, which includes a new generation of warehouse management system (WMS), a new generation of warehouse control system (WCS), and a robot scheduling system (RCS) for material control of mobile robots.

The reason for emphasizing the new generation is that compared to traditional software, although traditional software is very mature, most of it is aimed at traditional warehouse operations without too many automated equipment, in order to guide people to complete various tasks. In a modern logistics center, which typically includes automation equipment and robots of different brands and functions, such as AMR, shuttle cars, stackers, conveyor lines, and various sorting equipment, these equipment clusters need to be combined to complete the entire process of warehouse from receiving goods to shipping and order management. Therefore, software, as the command system, needs to change from “manager” to “management equipment”, Both its functionality and architecture need to be updated.

The Higris WMS warehouse management system is a self-developed cloud platform that supports comprehensive management of multiple warehouses, organizations, shippers, and businesses. The system has complete functions and covers all operational processes within the warehouse. It has flexible, convenient, and efficient expansion and development functions, which can meet the warehouse management needs of different characteristics, support multiple business models of B2B and B2C, and help enterprises improve their overall logistics operation level.

The WCS warehouse control system developed by Hebei Woke is a stable and efficient warehouse control software designed to meet the needs of large-scale automated material handling scenarios for customers. It adopts a distributed technology architecture, which is stable and efficient. Hebei Woke WCS system supports ultra large systems; Significant improvement in communication efficiency with PLC; Not dependent on WMS and main database, can run independently; When the software partially fails, it can still run with reduced efficiency.

In the future, the Hebei Woke HEGERLS four-way shuttle system will have a broader market development space, especially in the e-commerce retail industry that mainly focuses on dismantling and picking, the medical industry that requires higher picking efficiency and accuracy, as well as the manufacturing industry with special needs and the field of online logistics, which will be widely applied.

Post time: Feb-19-2024