With the rapid development of modern logistics industry, pallet four-way shuttle truck three-dimensional warehouse has become the mainstream form of automated storage with its advantages of high efficiency, intensive storage functions, and automated goods management. There are two main working modes for the pallet four-way shuttle car stereoscopic library, namely, a fully automatic pallet four-way shuttle car stereoscopic library and a semi-automatic pallet four-way shuttle car stereoscopic library. The docking of WMC, WCS system software, ERP, SAP, MES, and other management system software allows the goods to maintain a first in first out mode, eliminating manual disordered and inefficient operations, which greatly improves the efficiency of goods storage and utilization of warehouse space.

In fact, there are still many enterprises that have questions about the three-dimensional library of the pallet type four-way shuttle car: What kind of three-dimensional library is the pallet type four-way shuttle car three-dimensional library? What is the three-dimensional warehouse of the pallet four-way shuttle car?

About HEGERLS

Hebei Woke Metal Products Co., Ltd. was founded in 1996 and formerly known as Guangyuan Shelf Factory. It was an earlier company engaged in the shelf industry in North China. In 1998, it began to engage in the sales and installation of warehousing and logistics equipment. With many years of experience in intelligent storage solutions, it has become an advanced enterprise in intelligent storage shelves and intelligent storage equipment at home and abroad. The development strategy of Hebei Woke Metal Products Co., Ltd. is: high-precision shelf business (core business)+integration business (strategic business)+service business (emerging business). As the core business of our company, high-precision shelf business will continue to maximize customer benefits through strict material selection, sophisticated technology, and advanced cost control methods. As a strategic business of the company, in terms of products, the company now has advanced technologies such as parent and sub vehicle systems, four-way shuttle technology, multi-layer shuttle technology, ground light AGV technology, ground heavy AGV technology, cargo to person picking system, WMS (warehouse management system software), WCS (equipment control software) systems, as well as rotary shelf systems and light four-way shuttle vehicles developed and manufactured in recent years Heavy duty four-way shuttle vehicles, hoists, stackers, Kubao robots (carton picking robot HEGERLS A42N, lift picking robot HEGERLS A3, double deep bin robot HEGERLS A42D, telescopic bin lifting robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42M SLAM, multi-layer bin robot HEGERLS A42, etc.) have continuously enriched the variety of automated stand-alone products, In order to further improve the “shelf+robot=storage system solution”, Hebei Woke’s independent brand is HEGERLS, with a series of products and services covering nearly 30 provinces, cities, and autonomous regions in China. The products are exported to Europe, the United States, the Middle East, Latin America, Southeast Asia, and other countries and regions, and have achieved remarkable results overseas. There are also sales in China, and provide customers with more intelligent and efficient storage solutions. As an emerging business, service business focuses on efficiency, informatization, traceability, and automation to meet the future market demand of logistics and warehousing centers, and provides customers with better added value from the perspective of improving the performance of equipment systems and optimizing customer investment costs.

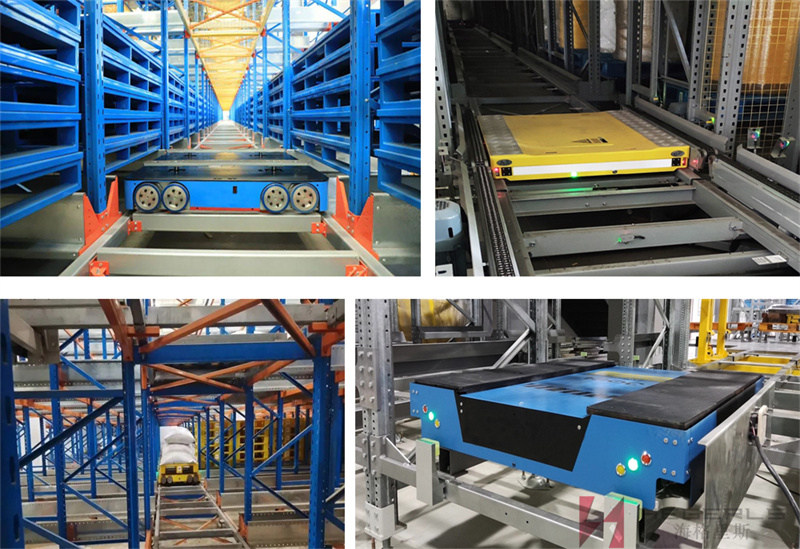

Especially in recent years, the HEGERLS brand has been well known by most enterprises at home and abroad, and its four-way shuttle car stereoscopic library has been put into use by large enterprises. The feedback received in the later stage is that using the pallet four-way shuttle car stereoscopic library not only can improve the utilization of storage space, but also can flexibly access goods, gradually moving manual operations towards intelligent and automated work mode, At the same time, it can also improve the flexibility and combination of logistics equipment to meet the construction needs of various warehouse conditions.

What is a pallet type four-way shuttle car stereoscopic library? What is the working principle of the three-dimensional warehouse of the pallet four-way shuttle car?

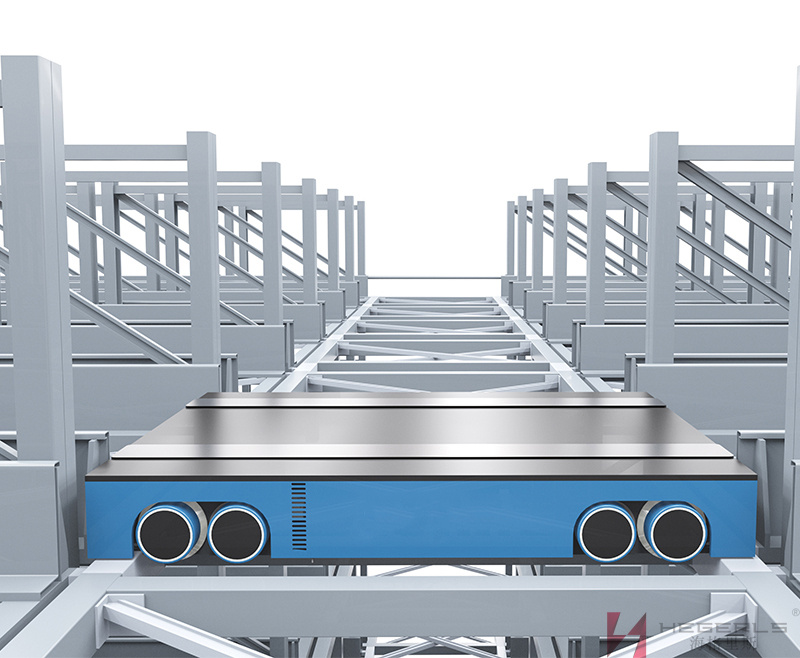

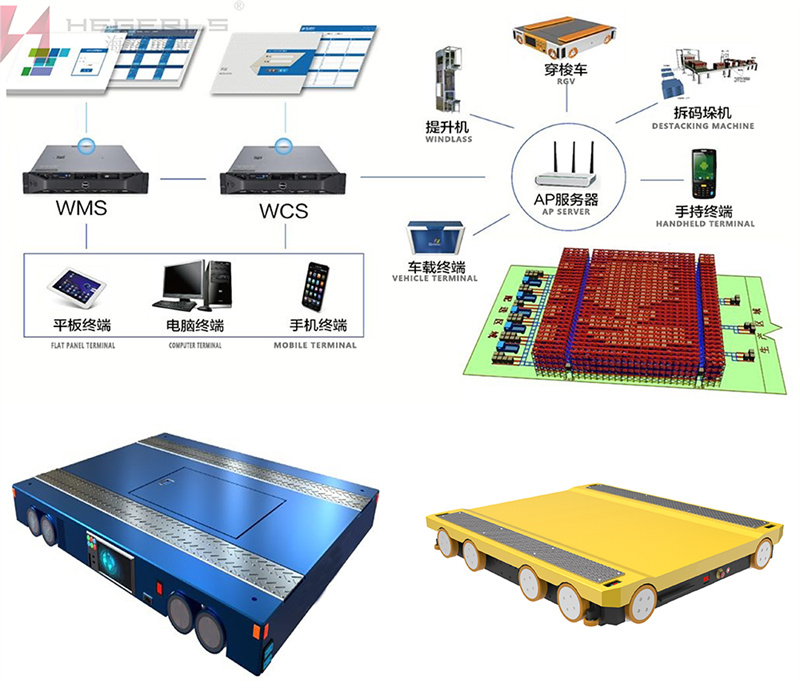

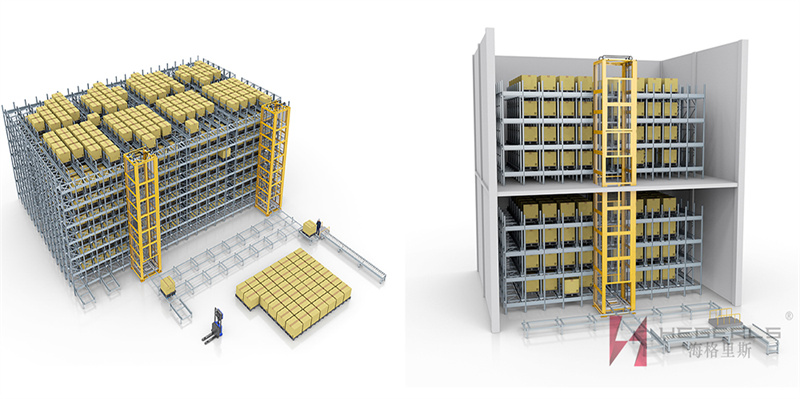

Pallet type four-way shuttle vehicle three-dimensional warehouse is a warehouse building with suitable structure, which adopts multi-layer pallet four-way shuttle type high level shelves, automatic conveyor system for incoming and outgoing pallets (including various conveyors, AGV docking facilities, etc.), pallet cargo size detection, barcode reading system, automatic sorting and sorting system or other automatic control systems, automatic identification system, communication system, computer monitoring and control system Computer Warehouse Management System (WMS) and other complex systems composed of logistics equipment and auxiliary equipment such as wire and cable bridges and power distribution cabinets, tray four-way shuttle vehicles and tray unit systems, loading racks and adjustment platforms, steel structure platforms, forklifts, etc., to achieve efficient and intensive warehousing operations for unit tray goods, Rely on manually operated handling and storage equipment such as forklifts to perform storage operations outside the steel rack storage area for the storage unit, and temporarily store the inbound and outbound cargo units on the exchange cargo location at the operating end of the rack storage location (such as the material rack, the manually operable rack, or the first pallet location for forklift operation). Then, use the pallet four-way shuttle to exchange goods between the inbound and outbound cargo locations Storage and transportation within the warehouse floor plane or the combination of cargo elevators to achieve layer changing operations between the warehouse floor planes, where the warehouse floor can exist independently in blocks or be connected through rail corridors. The entire warehousing operation is in a semi-automatic mode, and it is not possible to build a complete automated and intelligent continuous warehousing and warehousing operation through peripheral equipment such as conveyor lines in the warehouse; The fully automated mode includes: the storage unit can automatically integrate storage and handling within the warehouse with the automation of operations outside the warehouse based on the instructions of the electronic computer or the upper management information system. In the warehouse, the automatic warehousing operations are realized through the tray four-way shuttle system, cargo elevator, transportation and sorting system, and outside the warehouse, the automation of operations inside and outside the warehouse is constructed through the combination of transportation lines, AGVs, and other logistics equipment Intelligent docking operations truly realize dynamic logistics management. In this mode, the logistics of storage units rely on handling and turnover equipment (using a pallet four-way shuttle+cargo elevator) to achieve horizontal leveling and vertical layer changing movement. Storage and adjustment operations can be performed on storage units in designated cargo compartments, or automated operations for the entry and exit of cargo units can be performed using a pallet automatic conveyor system, achieving efficient automation of stored items The purpose of intelligent storage management is to achieve the storage management functions of buffering, adjusting, distributing, and balancing.

The HEGERLS tray four-way shuttle truck warehouse is an innovative construction of a new tray four-way shuttle truck warehouse system, which aims to maximize the overall operational efficiency of the system by redefining the high-density tray warehouse system business, replacing the commonly adopted strategy of optimizing the efficiency of individual products in the industry, accurately grasping customers’ needs for high-density, high-efficiency, and highly automated material storage.

So what are the highlights of the HEGERLS pallet four-way shuttle truck storage solution?

Service-based products

Hagrid HEGERLS will provide enterprises with a service-oriented intelligent shuttle vehicle storage product system. It will conduct autonomous optimization decomposition and task allocation through algorithm analysis of the HEGERLS intelligent warehouse operating system, in order to efficiently schedule the intelligent devices in the WCS controlled warehouse to better complete the assigned tasks.

Structural integration design

The four-way shuttle vehicle vertical warehouse system reduces the hardware product allocation process and software and hardware interface access debugging time during the project implementation process through the integrated design of the products required for the pallet storage three-dimensional warehouse business, and improves the feasibility of upgrading the intelligent shuttle vehicle three-dimensional warehouse.

Modular project implementation

Encapsulates details in handling, lifting, conveying, and scheduling, providing user interfaces, and reducing coupling between various links and equipment. Moreover, the design process of the system includes a high self-healing ability to achieve high fault tolerance and high availability. During the project implementation process, it is possible to maximize the design reuse of hardware devices and software systems, and meet more personalized requirements more quickly with a minimum of modules. At the same time, the system platform provides visual, remote, and preventive operation and maintenance services.

With safety assurance

For example, during the entire warehouse operation period, preventive measures can be taken to protect against emergency situations such as collision of handling equipment, derailment of equipment operation, and sudden failure of wireless network. Accurate hazard identification, system safety analysis, evaluation, and control can be carried out through hardware installation and implementation of multiple precision detectors to ensure its safety.

Post time: Mar-22-2023