In order to fulfill orders efficiently and cheaply, an automated and intelligent storage system is particularly important, which puts forward a strong demand for the application of logistics robots. The “goods to people” scheme based on robots can complete logistics operations such as replenishment, full container picking, scrap picking, and return, which has been in great demand in recent years. In such an environment, robot enterprises have sprung up, and various logistics robots have been rapidly introduced, and have been applied in logistics links such as handling, palletizing, picking, etc. the logistics robots specifically involved can be divided into automatic guided vehicles, palletizing robots, sorters, etc.

At the same time, in daily life, we can see that the traditional manual sorting operation mode not only has high error rate, large floor area and low sorting efficiency, but also, with the increasing cost of land and labor, the financial pressure of enterprises also comes. Therefore, the unmanned, efficient, low-cost, automated and intelligent storage mode has become the consensus of the industry. So, has this technology been realized by enterprises, and what will its development be like? With the rise of hegerls, more and more people pay attention to the research and development of hegerls intelligent automatic conveying and sorting equipment, and the market of conveying and sorting equipment is also full of potential.

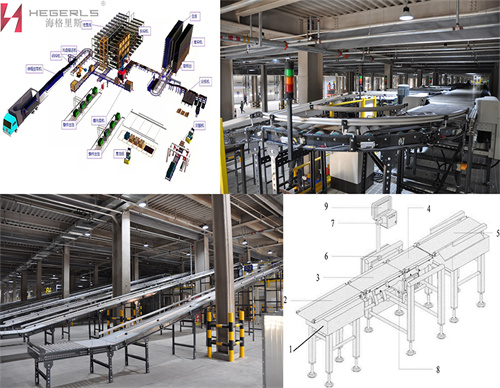

Hegris hegerls conveying and sorting equipment refers to the picking equipment that collects multiple orders into a batch, sorts goods after summing up according to the commodity category, and then classifies and centralizes goods according to different customers or orders.

Hagerls – features of conveying and sorting equipment

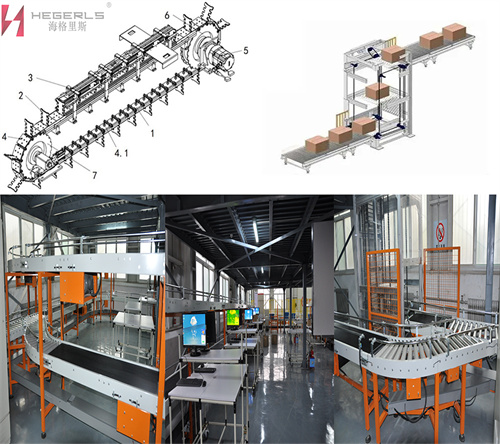

The conveying and sorting equipment manufactured by Hergels may sort goods continuously and in large quantities. Due to the automatic operation mode of assembly line used in mass production, the automatic sorting system is not limited by climate, time, human physical strength, etc., and can operate continuously. At the same time, due to the large number of sorting pieces per unit time of the automatic sorting system, the sorting capacity of the automatic sorting system is multiple times that of the manual sorting system, It can operate continuously for more than 100 hours, and can sort 7000 packaged goods per hour. If it is manual, it can only sort about 150 goods per hour. At the same time, the sorting personnel cannot work continuously for 8 hours under this labor intensity.

Hagerls – function of conveying and sorting equipment

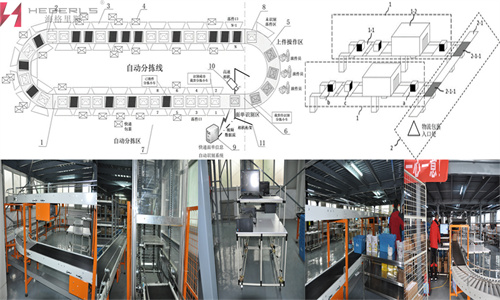

1) Improve space utilization: the automated logistics system uses high-rise shelves to store goods. The storage area can be developed at high altitude, reduce the floor area of inventory, and improve the utilization of storage space and storage capacity.

2) The accuracy of sorting is improved: the automatic sorting equipment adopts computer information management system, automatic material storage, sorting and handling equipment, so that the goods can be automatically accessed and sorted in the warehouse as required. In the logistics transportation link, the automatic logistics system automatically arranges the delivery and distribution according to the received order information, which can greatly improve the efficiency and accuracy of sorting and distribution.

3) Improve the level of warehousing and logistics management: it can strictly control and manage the warehousing, outbound, warehouse transfer, inventory checking and other operations of inventory, conduct real-time analysis and control of items, provide basis for enterprise managers to make correct decisions, significantly improve the speed and utilization of capital flow, and reduce inventory costs.

4) Realize the integration of informatization and management: logistics informatization is an important part of warehouse management. Through the seamless connection with the warehouse management system, the logistics information management system realizes the automatic transmission and reception of information between various systems of warehouse logistics, so as to integrate the warehouse management information. The automatic sorting equipment can automatically obtain and process the order information of other management systems, so as to ensure that the information can be obtained quickly, processed in time, accurately and efficiently summarize the distribution needs and prepare and distribute goods.

Then how should enterprises choose the appropriate logistics sorting and conveying equipment

1) Operation duration: when selecting sorting equipment, enterprises should consider the peak value in the peak season and the average value in the off-season, adjust the speed according to the cargo volume, and reserve space for expanding production capacity in the future.

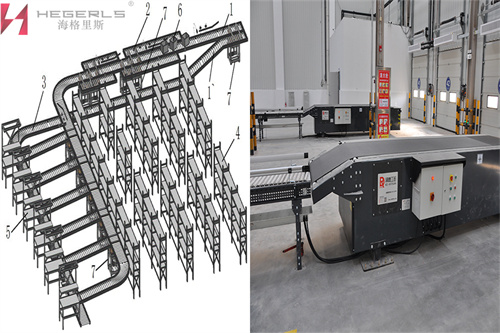

2) Efficient sorting accuracy: the sorting accuracy is directly related to the input cost of manual sorting and is an important indicator to measure the efficiency of sorting equipment. The accuracy rate of sorting equipment such as tilting wheel, cross belt and slider type can reach 99.99%, but there are great differences in the sorting range, and enterprises need to make choices according to their own conditions.

3) Low breakage rate: it is an important index to measure the efficiency of a conveying and sorting equipment. The friction of logistics sorting and conveying equipment is very small, basically without impact, which well protects the appearance and internals of goods, and has zero damage rate.

4) Flexible and flexible design: at present, the mainstream sorting equipment in the market is designed for large enterprises and large sites, which not only covers a wide area, but also has a large investment in the early stage, and cannot be changed after installation. For many small and medium-sized enterprises, customized products with flexibility and flexible design, which can adapt to equipment of different sizes, naturally become their items.

How can I get rid of the low manual efficiency in the sorting process, and how can I spend less time and snacks in sorting? Many customers have these problems. Hergels, the manufacturer of express automatic sorting equipment, tells you that as long as one sorting equipment can be easily solved, the express automatic sorting equipment can directly sort automatically, which can improve your sorting efficiency by 10 times. So how can the equipment of the express automatic sorting equipment manufacturer help the sorting to achieve 10 times the efficiency?

As the conveying and sorting equipment produced by Hergels, it is composed of automatic conveying lines, carrying cars and circular cross belts. In the past, 50000 pieces were sorted by manual sorting in a day, and 60000 pieces were sorted at peak hours. Now, this three-layer parcel express automatic sorting equipment can sort 700000 pieces in a single day, which is more than 10 times that of the manual sorter. Due to the automatic sorting of the equipment, the recognition accuracy is high, and the error rate is almost zero, However, some abnormal pieces still need to be sorted manually, which not only improves the sorting efficiency by 10 times, but also improves the efficiency by several times. Efficiency is on the one hand. Hergels also tells you that it is safe to use sorting. The sorting process can ensure the safety of goods sorting. Goods directly enter the sorting system from the unloading end, and goods do not fall on the ground. At the same time, it can also ensure the correct sorting of goods.

Intelligent automatic conveying and sorting integrated equipment | express automatic sorting equipment manufacturers tell you how to improve sorting efficiency by 10 times

In order to fulfill orders efficiently and cheaply, an automated and intelligent storage system is particularly important, which puts forward a strong demand for the application of logistics robots. The “goods to people” scheme based on robots can complete logistics operations such as replenishment, full container picking, scrap picking, and return, which has been in great demand in recent years. In such an environment, robot enterprises have sprung up, and various logistics robots have been rapidly introduced, and have been applied in logistics links such as handling, palletizing, picking, etc. the logistics robots specifically involved can be divided into automatic guided vehicles, palletizing robots, sorters, etc.

At the same time, in daily life, we can see that the traditional manual sorting operation mode not only has high error rate, large floor area and low sorting efficiency, but also, with the increasing cost of land and labor, the financial pressure of enterprises also comes. Therefore, the unmanned, efficient, low-cost, automated and intelligent storage mode has become the consensus of the industry. So, has this technology been realized by enterprises, and what will its development be like? With the rise of hegerls, more and more people pay attention to the research and development of hegerls intelligent automatic conveying and sorting equipment, and the market of conveying and sorting equipment is also full of potential.

Hegris hegerls conveying and sorting equipment refers to the picking equipment that collects multiple orders into a batch, sorts goods after summing up according to the commodity category, and then classifies and centralizes goods according to different customers or orders.

Hagerls – features of conveying and sorting equipment

The conveying and sorting equipment manufactured by Hergels may sort goods continuously and in large quantities. Due to the automatic operation mode of assembly line used in mass production, the automatic sorting system is not limited by climate, time, human physical strength, etc., and can operate continuously. At the same time, due to the large number of sorting pieces per unit time of the automatic sorting system, the sorting capacity of the automatic sorting system is multiple times that of the manual sorting system, It can operate continuously for more than 100 hours, and can sort 7000 packaged goods per hour. If it is manual, it can only sort about 150 goods per hour. At the same time, the sorting personnel cannot work continuously for 8 hours under this labor intensity.

Hagerls – function of conveying and sorting equipment

1) Improve space utilization: the automated logistics system uses high-rise shelves to store goods. The storage area can be developed at high altitude, reduce the floor area of inventory, and improve the utilization of storage space and storage capacity.

2) The accuracy of sorting is improved: the automatic sorting equipment adopts computer information management system, automatic material storage, sorting and handling equipment, so that the goods can be automatically accessed and sorted in the warehouse as required. In the logistics transportation link, the automatic logistics system automatically arranges the delivery and distribution according to the received order information, which can greatly improve the efficiency and accuracy of sorting and distribution.

3) Improve the level of warehousing and logistics management: it can strictly control and manage the warehousing, outbound, warehouse transfer, inventory checking and other operations of inventory, conduct real-time analysis and control of items, provide basis for enterprise managers to make correct decisions, significantly improve the speed and utilization of capital flow, and reduce inventory costs.

4) Realize the integration of informatization and management: logistics informatization is an important part of warehouse management. Through the seamless connection with the warehouse management system, the logistics information management system realizes the automatic transmission and reception of information between various systems of warehouse logistics, so as to integrate the warehouse management information. The automatic sorting equipment can automatically obtain and process the order information of other management systems, so as to ensure that the information can be obtained quickly, processed in time, accurately and efficiently summarize the distribution needs and prepare and distribute goods.

Then how should enterprises choose the appropriate logistics sorting and conveying equipment

1) Operation duration: when selecting sorting equipment, enterprises should consider the peak value in the peak season and the average value in the off-season, adjust the speed according to the cargo volume, and reserve space for expanding production capacity in the future.

2) Efficient sorting accuracy: the sorting accuracy is directly related to the input cost of manual sorting and is an important indicator to measure the efficiency of sorting equipment. The accuracy rate of sorting equipment such as tilting wheel, cross belt and slider type can reach 99.99%, but there are great differences in the sorting range, and enterprises need to make choices according to their own conditions.

3) Low breakage rate: it is an important index to measure the efficiency of a conveying and sorting equipment. The friction of logistics sorting and conveying equipment is very small, basically without impact, which well protects the appearance and internals of goods, and has zero damage rate.

4) Flexible and flexible design: at present, the mainstream sorting equipment in the market is designed for large enterprises and large sites, which not only covers a wide area, but also has a large investment in the early stage, and cannot be changed after installation. For many small and medium-sized enterprises, customized products with flexibility and flexible design, which can adapt to equipment of different sizes, naturally become their items.

How can I get rid of the low manual efficiency in the sorting process, and how can I spend less time and snacks in sorting? Many customers have these problems. Hergels, the manufacturer of express automatic sorting equipment, tells you that as long as one sorting equipment can be easily solved, the express automatic sorting equipment can directly sort automatically, which can improve your sorting efficiency by 10 times. So how can the equipment of the express automatic sorting equipment manufacturer help the sorting to achieve 10 times the efficiency?

As the conveying and sorting equipment produced by Hergels, it is composed of automatic conveying lines, carrying cars and circular cross belts. In the past, 50000 pieces were sorted by manual sorting in a day, and 60000 pieces were sorted at peak hours. Now, this three-layer parcel express automatic sorting equipment can sort 700000 pieces in a single day, which is more than 10 times that of the manual sorter. Due to the automatic sorting of the equipment, the recognition accuracy is high, and the error rate is almost zero, However, some abnormal pieces still need to be sorted manually, which not only improves the sorting efficiency by 10 times, but also improves the efficiency by several times. Efficiency is on the one hand. Hergels also tells you that it is safe to use sorting. The sorting process can ensure the safety of goods sorting. Goods directly enter the sorting system from the unloading end, and goods do not fall on the ground. At the same time, it can also ensure the correct sorting of goods.

Post time: Jul-20-2022