In the existing technology, warehousing logistics belongs to a labor-intensive industry. With the development of society and the rising cost of human resources, many enterprises in the society are currently using automated three-dimensional warehouses to solve the labor shortage, improve warehouse storage and other warehousing logistics problems. Among them, the intelligent four-way shuttle robot is an intelligent handling device that integrates four-way driving, track change in situ, automatic handling, intelligent monitoring and traffic dynamic management. In response to market demand and industry development needs, HEGERLS has successively developed standard, ultra-thin and narrow channel intelligent shuttle robots to meet various needs.

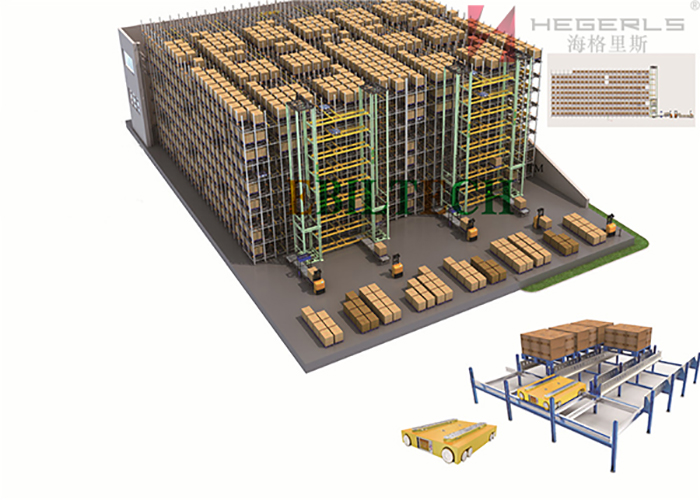

Four way shuttle truck warehouse is a new type of intensive intelligent storage system, which is generally divided into bin type and pallet type. The shelf structures between them are very similar, but there are differences in design details and four-way shuttle cars. At present, they have been widely used in medical, food, tobacco and other fields. The shelf is used to store goods, the intelligent four-way shuttle is used to transport goods on the shelf, and the software control system is used to control the operation of the four-way shuttle and other automatic equipment, and record the actual situation of the goods. The four-way shuttle stereoscopic warehouse can achieve intensive storage like the through shelf, greatly improving the utilization rate of warehouse space. The four-way shuttle makes it possible to automatically transport goods. It can transport goods to any position on the three-dimensional shelf to achieve all-round storage and sorting.

Operation principle of four-way shuttle

The four-way shuttle car refers to the shuttle car running along the closed circular track. That is, the four-way shuttle can run along the X axis and Y axis. By setting the X axis moving unit and Y axis moving unit, the belt motor car moves in the X axis direction and Y axis direction. The adjustment unit controls the lifting of the X axis moving unit. When moving in the Y-axis direction, the Y-axis moving unit drives the car body to move, and the X-axis moving unit is in a suspended state; When it is necessary to turn from the Y axis direction to the X axis direction, the adjustment unit can make the X axis moving unit move downward, so that the X axis moving unit drives the vehicle body to move, and the Y axis moving unit is in a suspended state, so as to achieve the purpose of switching from the Y axis direction to the X axis direction, and enable the four-way shuttle to move in a circular manner.

Q: As an intelligent logistics equipment manufacturing provider, what are the characteristics of the intelligent four-way shuttle designed and produced by HGRIS?

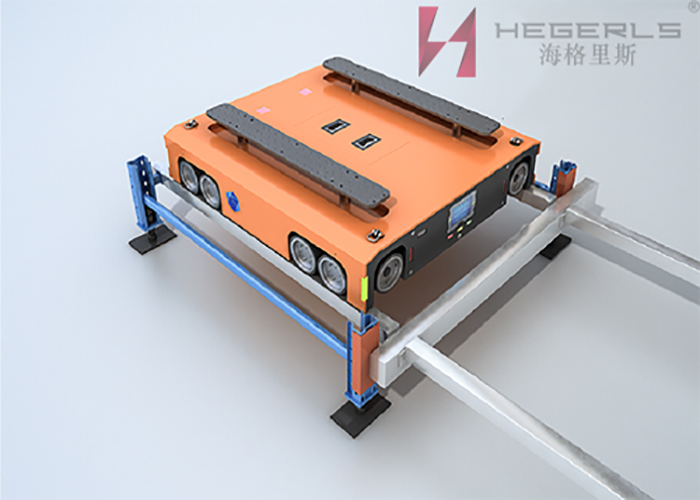

◇ The intelligent four-way shuttle cars produced and manufactured by Higelis adopt the combination of equalization and strengthening design to optimize the mechanical structure, so as to realize the low energy consumption, high efficiency, reliable and stable operation of the shuttle cars;

◇ The vehicle body of the whole machine shall have sufficient strength and compression resistance, and be not easy to deform;

◇ The wheel material shall be polyurethane. Because polyurethane has the advantages of high cutting resistance, high abrasion resistance, oil resistance, etc;

◇ Adopt multi-level hardware and software monitoring measures, set safe operation distance and judgment principles, and ensure the safe operation of the whole vehicle through specific operation limit stopper or anti overturning mechanism.

◇ Under the command of the real-time monitoring and dispatching information management system, multi vehicle cooperative operation can be realized;

◇ Efficient, accurate, intelligent scheduling, clean and low noise, flexible configuration;

Q: What are the advantages of the Hygris four-way shuttle in the specific functional design to ensure the efficient operation of the four-way shuttle rack system?

◇ Four way driving: It can drive in four directions on the special track of the stereo warehouse, and arrive at any designated location of the warehouse under WCS scheduling.

◇ Local reversing function: realize local reversing of vehicle body by changing corresponding wheels on both sides.

◇ Intelligent dispatching control mode: WCS online automatic dispatching mode, manual remote control operation mode and maintenance mode.

◇ Battery temperature sensing: conduct real-time detection on the battery temperature in the vehicle body. When the battery temperature exceeds the set upper limit, feed back the abnormal battery temperature information to WCS in real time. WCS dispatches vehicles to a special station outside the warehouse to avoid fire.

◇ Charging detection: when the vehicle reaches the charging position, abnormal charging occurs during the charging process, and abnormal information is fed back to WCS in real time. (Note here that the four-way shuttle car produced and manufactured by Hercules has its own characteristics in this respect, that is, the exclusive direct charging&wireless charging dual charging mode. The direct charging mode is applicable to the common production environment, and the wireless charging mode is applicable to the dust-proof&explosion-proof environment. The unique dual motor start&deceleration mode can realize stable operation under high acceleration and deceleration.)

◇ Automatic charging&resuming work: when the vehicle is lower than the set low power value, the relevant power information will be automatically uploaded to WCS, and WCS will dispatch the vehicle to perform the charging task. After the vehicle is charged to the set power value, the relevant power information will be automatically uploaded to WCS, and WCS will dispatch the vehicle to resume the task.

◇ Status display&alarm: status display lamps are installed at many places of the vehicle to clearly indicate various operating states of the vehicle. A buzzer is added to give an alarm in case of vehicle failure.

◇ Emergency power rescue: under abnormal circumstances, when the battery power is zero, use the emergency power, turn on the motor brake, and move the vehicle to the corresponding maintenance position.

◇ Pallet sensing: the vehicle has the function of pallet centering calibration and pallet detection

◇ Vehicle shock absorption: special polyurethane wheels shall be used to withstand pressure, wear resistance, pressure resistance and shock absorption.

◇ Position calibration: multi-sensor detection, supplemented by tunnel two-dimensional code, to achieve accurate positioning.

◇ Breakpoint continuation: when the vehicle is performing the goods in and out task, due to short-term non hardware failures such as obstacle avoidance and network disconnection, the vehicle will automatically continue to perform the unfinished task without human intervention until the abnormality is eliminated.

◇ Sleep&Wake up mode: After a long standby, enter the sleep mode to save power. When it needs to run again, it wakes up automatically.

◇ Obstacle perception: the vehicle has the obstacle perception function in four directions, and the remote obstacle avoidance detection&close stopping.

With the integration and development of technology, four-way vehicles will continue to optimize intelligent scheduling, improve operation efficiency, achieve more intelligent operations with faster speed and more accurate positioning, and relieve the high cost pressure, becoming a cost-effective modern logistics equipment.

HEGERLS is a three-dimensional warehouse and storage shelf company dedicated to the product development, design, production, sales and installation services of automated warehouse and storage shelves. It is also a one-stop integrated service provider of all-around, full series and full quality warehousing and logistics. It is one of the domestic manufacturers of automated warehousing and logistics equipment. It has a production and research base of 60000 ㎡, a fully automatic shot blasting unit There are 48 world advanced production lines, including numerical control stamping, longitudinal shearing of cold and hot coils, general profile rolling mill, X shelf rolling mill, welding, automatic electrostatic powder spraying, etc. There are more than 300 people in R&D, production, sales, installation and after-sales service, including nearly 60 people with senior technicians and senior engineers.

HEGERLS products mainly include automated three-dimensional warehouse, fully automated intelligent intensive warehouse, stacker three-dimensional warehouse, four-way shuttle vehicle three-dimensional warehouse, parent shuttle vehicle three-dimensional warehouse, multi-layer shuttle vehicle three-dimensional warehouse, heavy shelf, three-dimensional warehouse shelf, shuttle shelf, high shelf, steel loft platform, steel loft shelf, narrow aisle shelf, storage shelf, medium shelf, heavy shelf Cross beam shelf, corridor shelf, fluent shelf, cantilever shelf, logistics handling equipment, conveyor line, elevator, AGV, modular container, tool storage equipment, workshop station equipment, workshop isolation equipment, aerial work equipment, intelligent storage system, WMS storage management system, WCS warehouse control system, system integration, etc.

The shelves of Higelis stereoscopic warehouse are used in many industries, such as aerospace, cold chain of cold storage, electronics and appliances, hardware machinery, logistics and distribution, cloth textile, clothing toys, printing and packaging, building materials, instruments and meters, metallurgy and minerals, chemical coatings, household cabinets, security equipment, medical, tobacco, food and other industries.

Based on the business form of each customer, combined with site conditions, goods characteristics, reserve requirements, inbound and outbound frequency, picking and shipping methods, and enterprise development strategic planning, provide a full life cycle service process from pre-sales consulting, planning and design, project implementation to after-sales maintenance, and create customized solutions for customers to meet their material storage and circulation needs. Our solutions cover multiple links such as access, transportation, handling and picking, and the system platform can cover the whole process from warehousing to manufacturing. Whether it is the storage of pallets, bins or irregular materials, our company can easily cope with it, and finally win the trust of customers with professional and reliable scheme design and project implementation.

Post time: Sep-20-2022