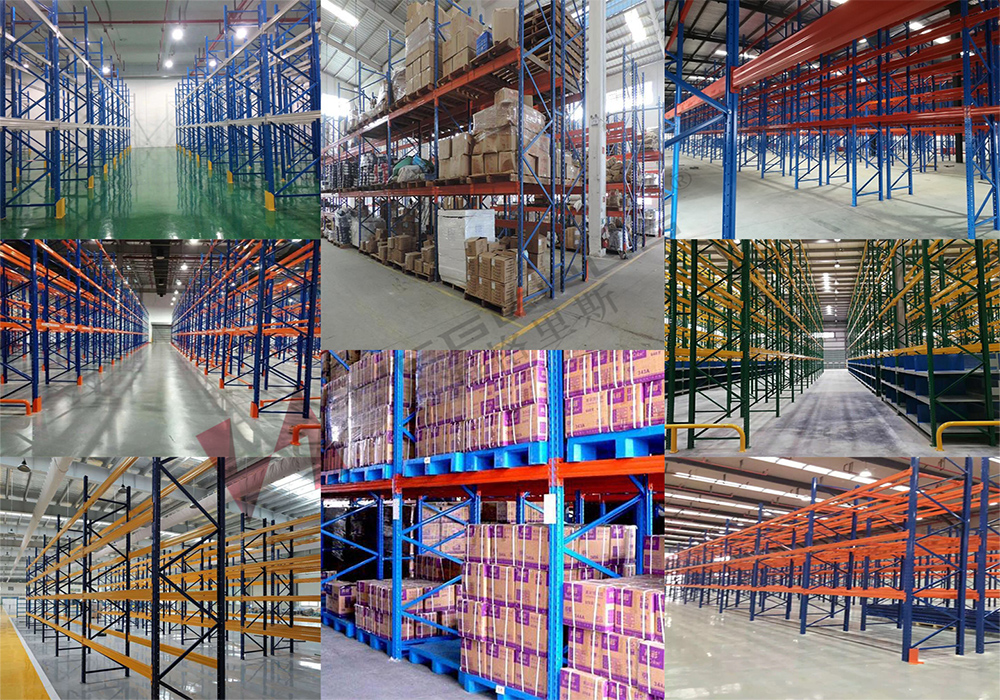

Many enterprises have their own warehouses to store products or goods. In order to facilitate management and increase the storage capacity of goods in the warehouse, some very large and heavy goods need heavy storage shelves. The higher the heavy storage shelf is, the higher the utilization rate of the warehouse is, and the stricter the requirements for heavy storage shelf are.

Heavy storage shelves, also known as beam type shelves, or cargo space type shelves, belong to pallet shelves, which are a common form of shelves in various storage shelf systems in China. The fully assembled structure in the form of column piece + beam is simple and effective. Functional accessories such as spacer, steel laminate (wood laminate), wire mesh layer, storage cage guide rail, oil drum rack and so on can be added according to the characteristics of the storage unit containerized equipment. Meet the storage of goods in different unit containerized equipment forms. So, what are the problems in the installation of Hebei heavy-duty shelves? What are the “six proofs” of Hebei heavy-duty shelves in use? What are the loading requirements for heavy storage shelves? Next, haigris small woven shelf manufacturer will take you to understand.

What are the problems in the installation of Hebei heavy-duty shelves?

1) All kinds of metrological verification and inspection equipment, instruments and equipment, instrument panels and machinery and equipment selected for the shelves meet the requirements of standard metrological verification.

2) The concealed decoration works of shelves before installation shall be inspected before the project is concealed and can be constructed again after reaching the standard.

3) This standard is formulated for the general installation and engineering acceptance of shelves, requiring shelves and improving economic benefits.

4) The rack installation shall be carried out according to the drawing. If any nonconformity is found during the construction, it shall be clearly put forward. The construction can only be carried out after the change is approved.

5) Self inspection shall be carried out during shelf installation.

Especially in the management area, it is important to take these six safety measures for heavy storage shelves. What are the “six proofs” of Hebei heavy-duty shelves in use?

1) Prevent top heavy: adhere to the principle of “light goods at the top and heavy goods at the bottom” when using.

2) Overload prevention: the weight of each layer shall not exceed the bearing capacity of heavy shelves.

3) Collision prevention: during the operation of the forklift, it should be handled as gently as possible to avoid collision with the shelves.

4) Prevent standing: when there is goods above the shelf, the operator shall not directly enter the bottom of the shelf to prevent accidental falling of goods and injury.

5) Prevent the use of non-standard items: non standard floor boards, trays, etc. are not allowed on heavy shelves.

6) Prevent the safety pin from falling off: if the safety pin falls off during use, the beam will fall off, or the installation will not be in place, and the shelf will be damaged or injured.

Next, haigris shelf manufacturers would like to say more for major enterprises:

Limit load and maximum load of heavy storage rack:

1) Maximum load the mass of the maximum pallet loading unit (including the pallet mass) allowed to be carried by each layer of cross beam and each column is called the maximum load. The maximum load of the shelf is the maximum allowable load of the shelf after considering overload and other factors.

2) The mass of the pallet loading unit (including the pallet mass) safely carried on each cargo position of the quota loading rack is called quota loading.

Loading requirements for heavy storage shelves:

1) Dynamic load refers to the maximum weight that can be lifted once by using electric forklift or manual hydraulic pallet handling. Generally, shelf pallet can bear 1.5t-2t, standard pallet can bear 1t, and ultra light pallet can bear 0.5T

2) Shelf load refers to the maximum weight allowed when goods loaded in plastic pallets are placed on shelves. Attention must be paid to the difference between dynamic load, static load, shelf load and vertical warehouse load. The difference of carrying capacity is closely related to shelf structure, ambient temperature and storage cycle. Generally, heavy pallets can withstand 0.7t-1t on the crossbeam shelf, while standard pallets can withstand 0.4t-0.6t.

3) Shelf loading has certain requirements for the permanent deformation and flexibility of plastic pallets. The national standard for flexibility is 30mm, but this is obviously biased. Hegris shelf manufacturers recommend using plastic pallets with elasticity no more than 20mm on the shelves. If it is an automatic three-dimensional warehouse, the requirements for flexibility are more strict, generally within 10mm.

4) Static load refers to the maximum weight that the plastic tray at the bottom can bear when stacking. Ordinary shelf pallets can withstand 6t-8t, standard pallets can withstand 4T, and ultra light pallets can withstand 1t static load.

The above is all today’s content. If you still want to know more about Hebei heavy-duty shelves, you can consult the online customer service of Hagrid. We will serve you wholeheartedly.

Post time: Sep-09-2022