E-commerce and new retail markets are further sinking, and warehousing and logistics automation is ushering in a new round of outbreak with the dual boost of policy and capital. As a technology-based enterprise that pays early attention to the R & D, design and scheme planning of box storage robot system in the industry, hagris has deep strength and sensitive foresight in warehousing and logistics technology. With robot technology and artificial intelligence algorithm as the core, hagris has developed a treasure box storage robot system to reduce costs and increase efficiency for customers, and create efficient, intelligent, flexible and customized warehousing automation solutions and whole process services.

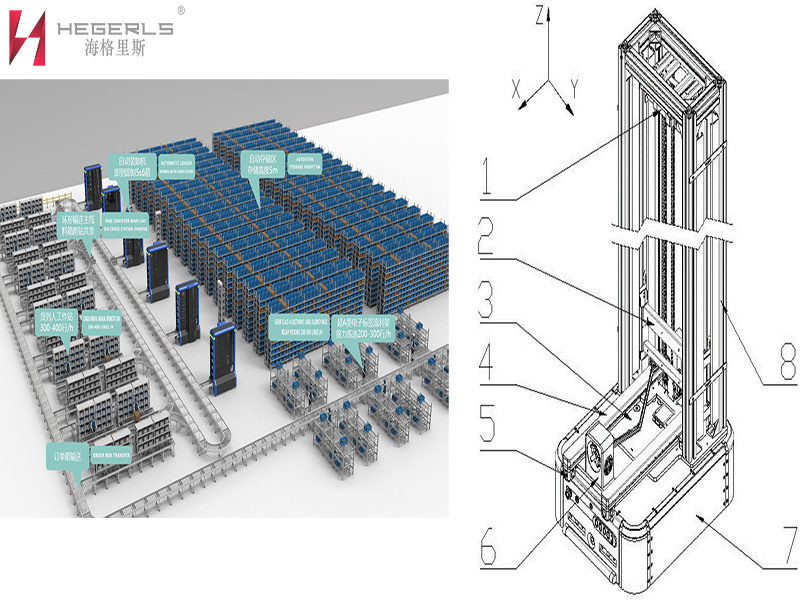

In the past, there were many problems in the factory, such as disordered goods placement and low inventory accuracy. With the continuous expansion of enterprise scale and the continuous increase of warehouse types and quantities, the contradiction of warehouse management has become increasingly prominent. Relying on the traditional manual operation mode will affect the operation efficiency of enterprises and the development of medical enterprises. Under the influence of intelligent manufacturing, enterprises begin to realize the necessity of warehouse logistics automation. Based on this, the kubao system of hagris is mainly composed of kubao robot, multi-function console, intelligent console, intelligent charging pile, goods storage device and intelligent management platform haiq, which can help the warehouse to carry out automatic management, realize intelligent picking, handling and sorting, accept customized requirements, and is suitable for a variety of application scenarios.

At the same time, focusing on the needs of customers, haggis has carried out iterative development of products with a more flexible and universal concept. Based on the multi bin robot hegerls A42, it has developed kubao hegerls a42d double deep bin robot, kubao hegerls a42n carton sorting robot, kubao hegerls a42t telescopic lifting robot and kubao hegerls a42slam robot, which are suitable for a variety of storage environments and meet the needs of customers Comprehensive requirements for efficiency. Next, we will introduce the carton picking robot hegerls a42n.

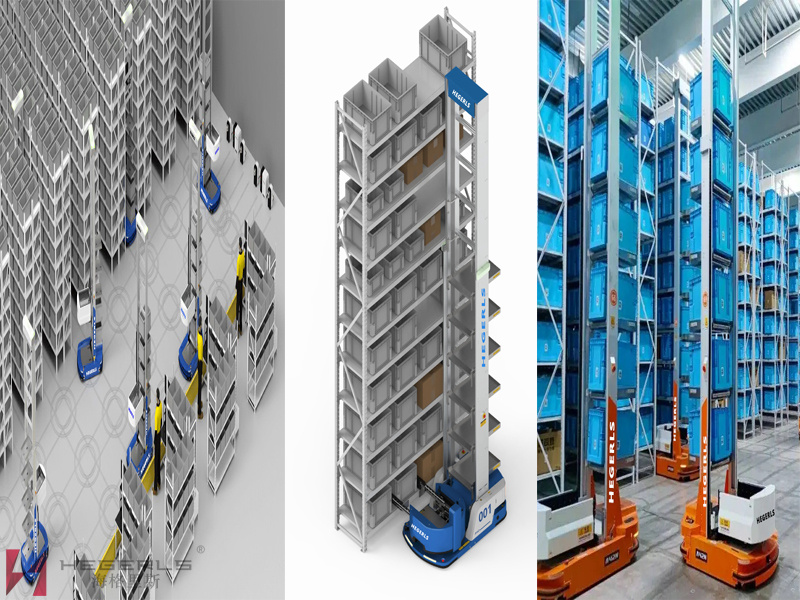

Hegerls a42n is the first carton picking robot (carton picking ACR) at home and abroad. It breaks the restrictions on container in the automated transformation of the robot warehouse for the first time, supports the mixed picking of cartons / bins of different sizes, and is configured with advanced 3D visual recognition technology. It can realize the picking and placing of goods without code recognition, save the steps of container labeling, support the repeated use of the original box, reduce the storage operation cost, and endow the storage with more flexibility, It is applicable to various business scenarios, such as picking by disassembly and full container picking, to meet various storage needs.

Carton picking robot hegerls a42n

Based on the hegerls a42n carton picking robot and hegerls A42 multi-layer bin robot, kubao independently innovates and develops 3D recognition technology, which can realize the mixed recognition, picking, access, handling and other functions of multi-size cartons / bins (the maximum load per trip can reach 300kg). As a new intelligent logistics handling equipment, hegerls a42n can realize intelligent walking in the storage space without the help of any track equipment. It has the functions of autonomous navigation, active obstacle avoidance and automatic charging. Compared with the traditional AGV “shelf to person” solution, kubao robot has smaller sorting granularity. According to the order requirements issued by the system, it truly realizes the transformation from the traditional “people looking for goods” to the efficient and simple “goods to people” intelligent picking mode. Compared with the solutions of stacker and automatic three-dimensional warehouse, kubao robot system can be deployed efficiently, with low overall deployment cost and stronger flexibility; At the same time, hegerls a42n supports docking with a variety of logistics equipment, including shelves, latent AGVs, robotic arms, multi-function workstations, etc. The flexible and flexible product design brings more operating space for the customized scheme, comprehensively improves the storage operation efficiency, optimizes the storage density, and realizes the automation and intelligent transformation of the storage industry. Applicable scenario: applicable to warehousing applications in 3PL, shoes and clothing, e-commerce, electronics, electric power, manufacturing, medical, retail and other industries.

Functional characteristics of carton picking robot hegerls a42n

Standard height: 4.33M, 1m-5.5m, flexible customization;

It supports carton / material box mixed picking and multiple use of the original box;

Compatible with carton and material box;

Take and release goods without code recognition, and adopt advanced 3D visual recognition technology;

The intelligent system supports a variety of business scenarios such as scrap picking and full container picking;

Carton and mixed box picking are more widely used scenarios.

With the kubao system, the automatic transformation of the warehouse can be completed within one week. The whole system can be online in about one month. Kubao robot can pick and carry multiple boxes or cartons at one time, thereby improving the work efficiency of workers by 3-4 times. Among them, kubao robot can be applied to 5-meter shelves and can increase the three-dimensional storage density of the warehouse by 80%-130%. Because it is easy to deploy and expand, it is also easier to transform and upgrade.

Post time: Jun-30-2022