With the continuous development of logistics automation and intellectualization, enterprises are no longer limited to the automatic upgrading and transformation of a single production line or warehouse. Therefore, the logistics of the whole plant is accelerating, and the era of large logistics is coming. However, in the current mobile robot market pattern, due to the lack of industry development, it is very difficult for a single manufacturer to independently complete the overall business of production line, storage and line side warehouse. Therefore, the combination of vertical and horizontal has become the strategic choice of many mobile robot manufacturers at this stage.

The strategic cooperation between HEGERLS and Hairou in innovation

In recent years, Hebei Walker Metal Products Co., Ltd. (self owned brand: HEGERLS) and Hairou Innovation announced a strategic cooperation, and jointly launched the first industrial technology laser SLAM multi-layer bin picking AGV robot, creating the best partner for the factory’s line side warehouse, opening a new era of industrial handling, and jointly enabling the upgrading of intelligent logistics industry.

About Hebei Walker Metal Products Co., Ltd. [Own brand: HEGERLS]

Founded in 1996, Hebei Walker Metal Products Co., Ltd. is an early company engaged in the shelf industry in North China. In 1998, it began to participate in the sales and installation of warehousing and logistics equipment. After more than 20 years of development, it has become a one-stop integrated service provider of warehousing and logistics that integrates warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc., and it is also a high-tech enterprise focusing on intelligent production and intelligent logistics. Its business covers warehousing shelves: shuttle racks Cross beam shelf, stereoscopic warehouse shelf, attic shelf, floor shelf, cantilever shelf, mobile shelf, fluent shelf, drive in shelf, gravity shelf, medium shelf, dense shelf, steel platform, anti-corrosion shelf, etc; Storage stereoscopic warehouse: shuttle stereoscopic warehouse, beam stereoscopic warehouse, attic stereoscopic warehouse, floor type stereoscopic warehouse, cantilever stereoscopic warehouse, mobile stereoscopic warehouse, fluent stereoscopic warehouse, drive in stereoscopic warehouse, gravity stereoscopic warehouse, etc; Intelligent storage equipment: shuttle car, two-way shuttle car, four-way shuttle car, stacker, sub main car, elevator, intelligent conveying and sorting system, turnover box, pallet, storage cage, general AMR controller, automatic forklift, etc; Warehousing and storage system and solutions: shuttle truck+forklift, shuttle truck+stacker, sub bus+elevator, four-way shuttle truck, AS/RS stacker, intelligent transportation and sorting system, visual industrial system software and intelligent vision solution, to provide one-stop solutions and services for customers in all industries, and to promote the transformation and upgrading of industrial informatization, digitization and intelligence.

HEGERLS – laser SLAM multi-layer bin picking AGV robot

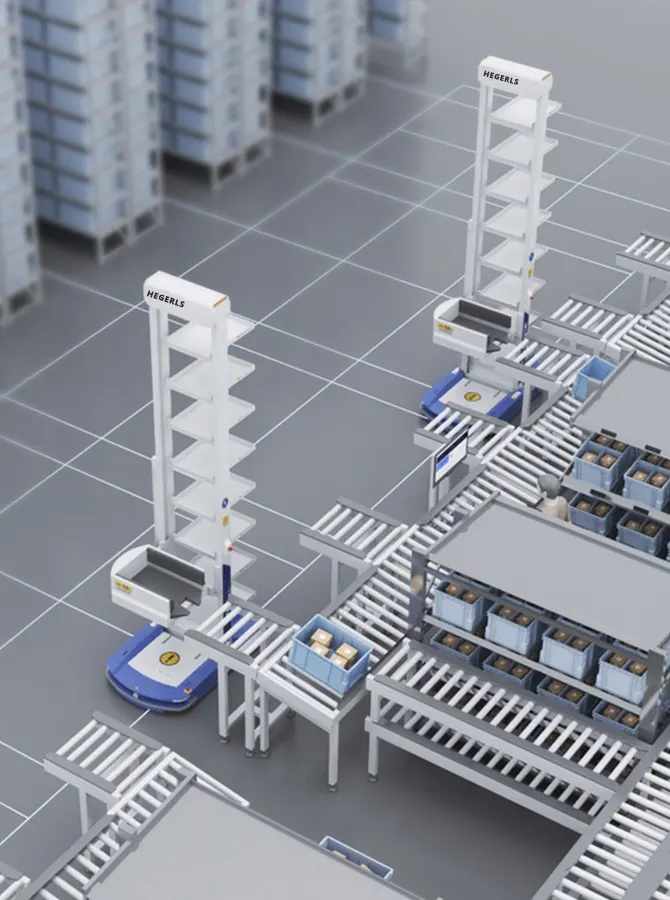

The first industrial technology laser SLAM multi-layer bin picking AGV robot, jointly developed by HEGERLS and Hairou Innovation, can realize laser SLAM navigation. It is equipped with SRC core controller, and has four functional highlights. It integrates navigation, safety, and multi-function. It realizes flexible docking, accurate picking and placing, and efficient handling. It becomes the best partner of the factory line side warehouse, enabling intelligent manufacturing. In recent years, this new robot has attracted the attention of large and medium-sized enterprises, and most of them have put it into use, which has been unanimously praised and favored.

SLAM (Simultaneous Localization and Mapping) is called real-time positioning and map building technology. The robot has the functions of intelligent picking and handling, autonomous navigation, active obstacle avoidance and automatic charging. The laser SLAM scans the contour of the environment to build a point cloud map of the environment, and then matches the constructed point cloud map with the real-time point cloud scanned by the laser for positioning and navigation. The industrial technology laser SLAM multi-layer material box picking latent AGV robot is a high-performance box type storage robot integrated with advanced software and hardware technology. It is specially designed for line side warehouse scenarios, and uses laser SLAM navigation technology to achieve accurate positioning. The industrial technology laser SLAM multi-layer material box picking latent AGV robot can move forward and backward, and can rotate to any angle in situ. At the same time, it has the characteristics of high stability and high-precision operation. The perfect safety obstacle avoidance module and active and passive safety protection measures of the robot can realize the separation of man and machine. When people accidentally enter the robot area, they can also intelligently identify, alarm and realize shutdown protection. In addition, the software system matched with the industrial technology laser SLAM multi-layer bin picking latent AGV robot can handle the needs issued by business related systems, which is extremely suitable for the flexible management of line side warehouses. The software system automatically processes and collects material information throughout the whole process, accurately and efficiently implements the receiving and shipping, picking and distribution instructions, realizes the intelligent management of the line side warehouse, realizes the orderly picking of goods out of the warehouse and the accurate warehousing of goods batches, and helps customers achieve lean production.

HEGERLS – laser SLAM multi-layer bin picking AGV robot focuses on solving storage pain points

❑ Super human design

The industrial technology laser SLAM multi-layer material box picking latent AGV robot adopts superhuman design to achieve free lifting of 0.4 m~1.86 m, adapt to manual operation mode, flexibly match multiple operation heights, create a comfortable operation experience, and make human-computer interaction more friendly.

❑ Super flexible deployment

Responding to the changing working environment, the industrial technology laser SLAM multi-layer bin picking latent AGV robot adapts to the flexible change of the operation site, without two-dimensional code navigation, breaks through the traditional assembly line restrictions, and realizes discrete manufacturing and flexible enabling intelligent manufacturing.

❑ Super flexible docking

The business of the factory is complex and diverse, and the demand for logistics equipment is also different. The industrial technology laser SLAM multi-layer bin picking latent AGV robot can flexibly dock with a variety of equipment, including roller, shelf, latent AGV, artificial workstation and other operating platforms, which can be taken and placed freely, and can be docked infinitely as you want, with a wider range of application scenarios.

❑ Ultra precise taking and placing

The laser SLAM multi-layer bin robot support system is connected, and visual AI is used to achieve accurate picking and placing, intelligent picking and handling of materials, and help super efficient operation.

❑ Self handling

The chassis of the industrial technology laser SLAM multi-layer bin picking latent AGV robot is equipped with drive wheels and driven wheels. The dual wheel differential mode is adopted, which is conducive to the robot driving and lane changing in narrow places. The robot can move forward and backward quickly, and can also rotate and change direction at any angle in the original place. The industrial science and technology laser SLAM multi-layer material box picking latent AGV robot follows the handling and walking instructions issued by the computer scheduling system, can adjust the running speed, direction, braking, etc., and supports reporting the walking status to the scheduling system, so as to achieve unmanned autonomous handling. The multiple safety mechanisms of the robot itself can ensure the safety of personnel and robots in the process of autonomous handling.

❑ Self charging

The industrial technology laser SLAM multi-layer material box picking latent AGV robot can realize the self charging function. When the power of the robot is almost exhausted, the voice prompts that the power is insufficient, and the robot will automatically walk to the charging pile position according to the command issued by the dispatching system. The charging port of the robot is successfully connected with the charging pile to start charging. The robot has a built-in charging protection circuit to ensure its safe charging. After fully charged, the robot will automatically stop charging.

❑ Safety protection

The industrial technology laser SLAM multi-layer material box picking latent AGV robot has multiple safety protection functions to ensure safe and reliable operation of personnel and the entire system.

❑ Ultra safe navigation

The industrial science and technology laser SLAM multi-layer bin picking latent AGV robot is built with SRC controller developed by Xiangong Intelligence, which provides the robot with basic functions such as map building, positioning, navigation, multi machine scheduling, automatic charging, 3D obstacle avoidance, etc., realizes super safe navigation, protects the safety of workers, and is suitable for complex man-machine mixed field environment, which is more intelligent and efficient.

❑ Audible and visual alarm and voice prompt

The industrial technology laser SLAM multi-layer bin picking latent AGV robot provides an audible and visual alarm function, and users can know the operation status of the robot in real time through the audible and visual alarm information.

❑ Emergency stop safety protection

In order to ensure the safety of the robot and operators, the robot body is equipped with four emergency stop buttons, which are respectively in the left front and right rear of the chassis shell, and on both sides of the left and right lifting columns. Emergency stop safety protection can maximize the safety of personnel and equipment in various emergencies. Press the emergency stop button to trigger the emergency stop safety protection, and rotate the button clockwise to reset the emergency stop button.

❑ Lifting protection

The lifting anti falling electromechanical interlocking device, located under the lifting column on the right side of the robot, is used to prevent the lifting and falling when the maintenance personnel overhaul the robot. When the lifting anti falling switch is turned to the “lifting locking” position, the robot lifting mechanism enters the locking state, the lifting mechanism stops, and the electrical circuit is cut off to provide dual safety protection. When the lifting anti falling switch is pulled to the “lifting unlocking” gear, the lifting motor resumes normal lifting action. When the maintenance personnel perform routine maintenance and troubleshooting on the robot, they must turn the lifting anti falling switch to the “lifting lock” position to prevent the fork from falling and protect the safety of personnel.

❑ Collision protection

The front and rear edges of the chassis of the industrial technology laser SLAM multi-layer bin picking latent AGV robot are respectively equipped with safety contacts for collision protection of the robot, which can effectively protect the safety of the robot and personnel. When the obstacle is lower than the detection height of the laser radar obstacle avoidance module, it may hit the safe contact of the robot. When hitting an obstacle, the safety contact is pressed and information is sent to the control circuit, and the robot emergency brakes and enters the safety protection mode. At this time, the top red light is on for a long time, the front and rear indicator lights of the chassis are on, and the buzzer sends out a continuous drip alarm sound, accompanied by a voice prompt.

❑ Network communication

The industrial technology laser SLAM multi-layer bin picking latent AGV robot supports Wi Fi or 5G and other communication methods. It can be connected to the intelligent management platform through wireless network, which can monitor the working status and health status of the robot in real time. When an exception occurs, the robot reports the exception information to the intelligent management platform through the network, and technicians can solve the problem according to the exception log and other information.

❑ Intelligent management

The industrial technology laser SLAM multi-layer bin picking latent AGV robot is a highly intelligent robot that supports access to the intelligent management platform and third-party management platform. The intelligent management platform is the intelligent brain of the robot, which can connect with the external management system, process relevant business processes, conduct data analysis and visual management; Ensure the real-time scheduling of multiple robots and various logistics equipment, realize the prediction and monitoring of system health, and optimize the system based on reinforcement learning and in-depth learning. The intelligent management platform can realize intelligent warehousing, warehousing and other operations. The operator only needs to click the operation button on the software interface, and the robot will independently complete various tasks of the order under the scheduling system.

The first laser SLAM multi-layer bin robot jointly launched by HEGERLS and HAIROO Innovation will play a significant role in line side handling, achieve flexible docking between production equipment and efficient operation of bins, and create greater value for customers. At the same time, in the innovative cooperation strategy between HEGERLS and HAIROO, HEGERLS has also introduced several types of Kubao robots: multi-layer bin robot HEGERLS A42, double depth bin robot HEGERLS A42D, carton picking robot HEGERLS A42N, telescopic lifting bin robot HEGERLS A42T, gradually covering a variety of application scenarios of box storage robots, focusing on solving more storage pain points, and providing customers with more value increment. In the future, the two sides will continue to explore more possibilities of intelligent manufacturing and intelligent warehousing to achieve common development.

Post time: Nov-02-2022