Intelligent Handling Robot | How will Hagrid continue to promote the intelligent upgrading and development of industry and logistics?

Access, handling, and sorting are common functions in the logistics industry, but they are very different for each industry. For example, in the field of new energy batteries, they transport batteries ranging from 50KG to 200KG; In the express delivery industry, the materials to be processed are flat parts, envelopes, and so on, so the technology, hardware, and software required for robots vary in different scenarios.

In the rapid development process of Hebei Woke for many years, thanks to the support of many strategic partners, we continue to focus on the three core scenarios of access, handling, and sorting, and layout the technology research and production of robots and automation equipment products in multiple directions. At the same time, we strengthen the in-depth application of software products such as WMS, WCS, RCS in various industries and fields.

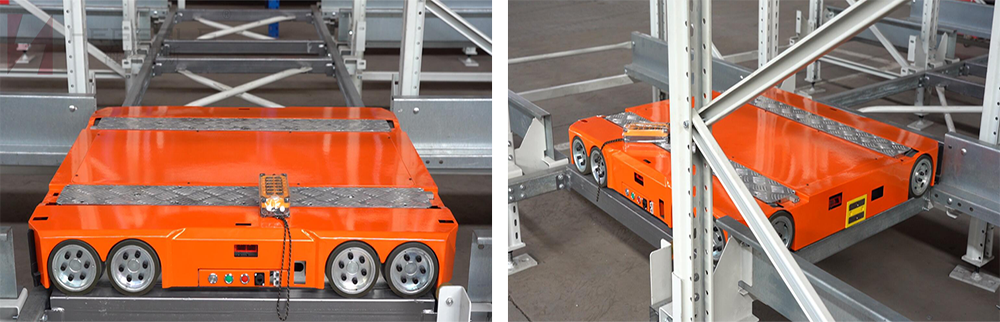

The four-way shuttle vehicles and spare parts under the Hebei Woke Hegerls brand adopt international standards and have passed the European CE certification. The HEGERLS four-way shuttle has been designed to comply with EU standards since its inception, and has undergone comprehensive verification and testing from multiple perspectives such as motion, stability, fault mechanisms, personnel safety, electrical, and environmental aspects. Through reasonable software and hardware design, it meets the high-performance and safety requirements of various pallet storage and logistics scenarios. The flexibility and scalability of the shuttle system ensure the stability and sustainability of project use; At the same time, Hebei Woke relies on its strong planning and design, software development, and integration implementation capabilities to create customized and specialized logistics centers according to the different needs of users.

The HEGERLS is a unique box solution based on the “rack, shuttle, and hoist” module configuration, which can be programmed with the hoist system to perform tasks such as picking up, transporting, and placing goods. It can reach any cargo location, achieve true three-dimensional operations, and further improve the flexibility and fault tolerance redundancy of the equipment; And it can communicate with the upper computer or WMS system, combined with barcode and other recognition technologies, to achieve automated recognition, access and other functions. Thanks to its excellent sorting function, the HEGERLS four-way shuttle can also use a multi-level path control system to plan reasonable paths, transport goods in an orderly manner to the manual picking table, and quickly and accurately complete orders and ship them in a timely manner. Full process control management can be implemented for each stage of warehousing, and data management can be achieved for the quantity, specifications, date, storage room number, warehouse area number, etc. of the material boxes. Standardized operations can be carried out for all stages of warehousing, outbound, etc.

The use of the Hegerls shuttle system can significantly increase storage density and achieve fast access to material boxes. The intelligent scheduling system can achieve functions such as intelligent scheduling, obstacle avoidance, and path optimization. Moreover, each shuttle is a backup of other shuttle vehicles. When a single shuttle vehicle malfunctions, the system can dispatch nearby shuttle vehicles to provide support and replace it to complete tasks. The system’s operational ability is almost unaffected.

It is worth mentioning that based on a mature capacitor power supply system, the Hegelis HEGERLS four-way shuttle can complete automatic charging during the intermittent stage of operation. Charging for 10 seconds can meet the 3-minute usage needs of the shuttle, and it can be recharged millions of times. The maximum operating speed can reach 5m/s, and the acceleration speed is 2m/s ², The service life can support working 24 hours a day.

Not only that, Hebei Woke has also achieved the integration from the bottom level robot bike system to the overall upper level warehousing and logistics system. Among them, the Hebei Woke RCS intelligent multi device cluster scheduling system can meet the large-scale robot cluster scheduling needs of users in both intelligent manufacturing and intelligent logistics systems. It adopts a microservices architecture and AI algorithms, which can directly control robots and other peripheral intelligent devices, and interface and cooperate with WMS, ERP, and WCS to fully leverage and optimize the efficiency of smart robot equipment, thereby improving the operational efficiency of the equipment.

One stop service

At present, Hebei Woke has formed a comprehensive solution for the research and development and manufacturing of core high-end equipment, including logistics system consulting and planning, software development, system integration, operation guidance, as well as multi-layer shuttle cars, four-way shuttle cars, two-way shuttle cars, stacker cranes, material box robots, high-speed elevators, AGVs, conveyor sorting systems, etc. It can provide third-party logistics, manufacturing, express delivery, 3C, new energy, e-commerce, etc Retail and other industries provide one-stop services.

Multi warehouse “goods to person” solution

Hebei Woke is continuing to explore application scenarios and solutions for shuttle updates, which will be applicable to picking, sorting, and other functional scenarios. It is making technological breakthroughs towards highly intelligent application scenarios such as unmanned warehouses and black light factories, in order to achieve 24-hour unmanned operations in factories and warehouses.

Post time: Feb-20-2024