With the updating and iteration of new technologies such as artificial intelligence and the Internet of Things, the digitalization of the logistics industry and intelligent warehousing have become a trend. Driven by the "Internet plus" strategy, China's intelligent warehousing has developed rapidly. It is deeply integrated with Big data, cloud computing and other new generation Internet technologies. The whole industry of intelligent warehousing is moving towards the direction of efficient, convenient and low-cost operation. More and more enterprises have realized the importance and development prospects of intelligent warehousing logistics system.

Hebei Woke Metal Products Co., Ltd. can help traditional manufacturing enterprises handle daily warehouse operations more accurately and efficiently, as well as the circulation of parts, semi-finished products, and finished products, effectively improving operational efficiency, reducing logistics costs, reasonably controlling inventory, and maintaining a leading position in fierce competition. In the digital field of warehousing and logistics, Hebei Woke Metal Products Co., Ltd. uses highly flexible intelligent equipment as the carrier, and a global simulation and professional implementation team as the guarantee. It integrates intelligent, flexible, and customized products and technologies such as laser and visual integrated navigation applications, core control algorithms of intelligent logistics equipment, and non-standard customized equipment integration, providing a comprehensive and comprehensive series for various large, medium, and small

enterprises Full quality warehousing and logistics one-stop integrated services.

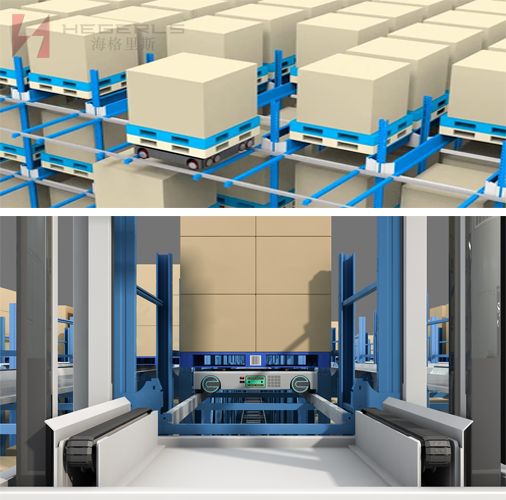

At present, Hebei Woke Metal Products Co., Ltd. has been developing since 1996, and its independent brand HEGERLS has increasingly diversified its product categories. It provides integrated automation equipment services such as various shelves, shuttle boards, shuttle mother cars, multi-layer shuttle cars, four-way shuttle cars, tunnel stackers, high-speed elevators, automatic conveyors, robotic arms, high-precision elevators, and related supporting systems. Among them, the HEGERLS intelligent four-way shuttle robot developed by Hebei Woke Metal Products Co., Ltd., as an innovative form of dense shelves, is not only suitable for industries with fewer SKUs and huge reserves of a single variety served by traditional dense shelves, but also can flexibly design shelf depths. By utilizing the combination of multiple depth positions on shelves, this system can achieve dense storage of ABC type goods on the same shelf. Due to its many outstanding advantages in improving storage efficiency and warehouse space utilization, the product is widely used in various industries such as medical, e-commerce, clothing, books, rail transit, automobiles, new energy, semiconductors, etc., implementing numerous logistics projects, and building multiple large and medium-sized modern logistics centers and production oriented three-dimensional warehouses.

Empowering enterprises to reduce costs and increase efficiency

According to measured data from a raw material production enterprise, under the same warehouse area, using a stacker storage solution can obtain 8000 storage spaces, while using the HEGERLS intelligent four-way shuttle storage solution can obtain 10000 storage spaces, with a space utilization improvement of over 20%.

In addition, due to the different requirements for pallets compared to stackers, the HEGERLS intelligent four-way shuttle can use thinner pallets, which can save pallet costs by over 40%; In terms of energy consumption, using the HEGERLS intelligent four-way shuttle vehicle storage solution can also save over 65% of electricity costs; The most important aspect is also reflected in the construction cycle. The implementation cycle of the HEGERLS intelligent four-way shuttle vehicle storage solution can be controlled within 5 months, which is more than 50% shorter compared to the stacker crane storage solution.

So, from a series of scenarios such as number of goods, project cycle, power cost, pallet cost, etc., HEGERLS intelligent four-way shuttle system is a more cost-effective warehousing solution that can help enterprises achieve cost reduction and efficiency increase.

Analyzing from the perspective of technical details how HEGERLS intelligent four-way shuttle achieves optimized scenarios

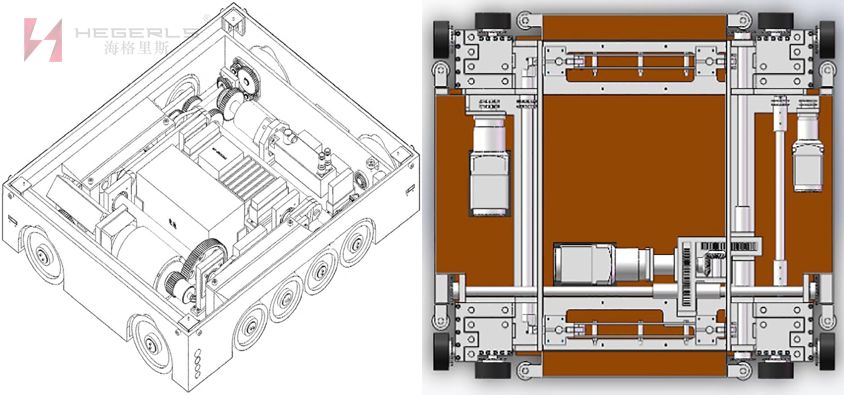

Firstly, from the perspective of space utilization, the thinner the shuttle car body, the higher the utilization rate of shelf space. The HEGERLS intelligent four-way shuttle developed, produced, and manufactured by Hebei Woke has a height of only 12.5CM, which greatly reduces the waste of shelf space.

Furthermore, in terms of speed, the HEGERLS intelligent four-way shuttle can achieve a reversing speed of 2.5S in unloaded scenarios, and 3.5S in loaded scenarios, which is relatively faster than other products in the industry. At the same time, Hebei Woke has also optimized the acceleration of the HEGERLS intelligent four-way shuttle vehicle body for frequent start and stop situations, with an unloaded acceleration of up to 2m/s2.

Compared to other four-way shuttle products, the HEGERLS intelligent four-way shuttle can save 30% of its time on the same turning route.

In addition, the HEGERLS intelligent four-way shuttle system can also be combined with

other warehousing solutions such as autonomous mobile robots, palletizing robots, and visual inventory workstations for use. For example, in a clothing project undertaken by Hebei Woke, more than 80 HEGERLS intelligent four-way shuttle cars were used, and can perform full box picking of over 10000 SKUs and tens of thousands of cargo spaces.

Post time: Jul-06-2023