With the accelerated transformation and upgrading of domestic and foreign manufacturing industries, more and more small and medium-sized enterprises also need to upgrade their logistics intelligence. However, they are often limited by practical conditions such as warehouse height, shape, and area, as well as market uncertainty factors. In this regard, compared to using traditional automated three-dimensional warehouses, major small and medium-sized enterprises are more inclined to choose logistics systems with higher levels of intelligence and flexibility. Among numerous intelligent automated storage systems, the four-way shuttle system for pallets has become a popular automated intensive storage system in the market due to its advantages of flexibility, flexibility, intelligence, energy conservation and environmental protection, large capacity improvement space, and strong adaptability.

The main application of tray type four-way shuttle vehicles is in dense storage, especially in cold chain logistics systems. In cold chain systems, especially those below -18 ℃, using a four-way shuttle for storage can significantly improve space utilization and greatly improve the environment of the work area, making the work of operators more comfortable. In other application fields, there are many four-way shuttle cars, such as using a four-way shuttle car system as a temporary storage for shipping, which is a good application that can greatly save space and achieve automated operations. In addition, using a four-way shuttle instead of a conveyor system for long-distance transportation is also a good choice.

Industry insiders have stated that the system technology barriers for four-way shuttle vehicles with pallets are relatively high, such as in system scheduling, positioning and navigation, perception technology, structural design, and other aspects. In addition, it will also involve coordination and docking between multiple software and hardware, such as hardware equipment such as layer changing elevators, track conveyor lines, and shelf systems, as well as software such as equipment scheduling control systems WCS/WMS. Unlike AGV/AMR, which operates on a flat surface, the four-way shuttle truck travels on a three-dimensional shelf. Due to its unique structure, it poses many challenges, such as accidents such as pallets, dropped goods, and collisions between vehicles. In order to reduce risks and ensure safe operation, the four-way shuttle truck for pallets has strict requirements for process, positioning accuracy, path planning, and other aspects.

About Hebei Woke HEGERLS

Hebei Woke Metal Products Co., Ltd. focuses on the research and application of 5G Internet of Things and artificial intelligence technology, creating perceptible, linkable, and schedulable intelligent logistics solutions to help enterprises of all sizes improve logistics efficiency and achieve intelligent upgrades. Building a smart logistics operating system with AI, empowering innovative automated logistics equipment, and providing a new generation of modular, flexible, and scalable solutions are the differences between Hebei Woke HEGERLS and traditional integrated manufacturers. The HEGERLS pallet four-way shuttle car is independently developed, produced, and manufactured by Hebei Woke. It is an intelligent storage and handling system that integrates four-way driving, automatic handling of changing tracks in place, intelligent monitoring, and traffic dynamic control. Based on this, Hebei Woke HEGERLS has made frequent efforts in the field of smart supply chain logistics. In terms of software, it has integrated storage and distribution, dynamic supervision, modular configuration, three-dimensional configuration, and good scalability. It can be widely used in online edge warehouses, intelligent dense storage warehouses, and logistics transfer centers, and is fully applicable to unmanned warehousing warehouses.

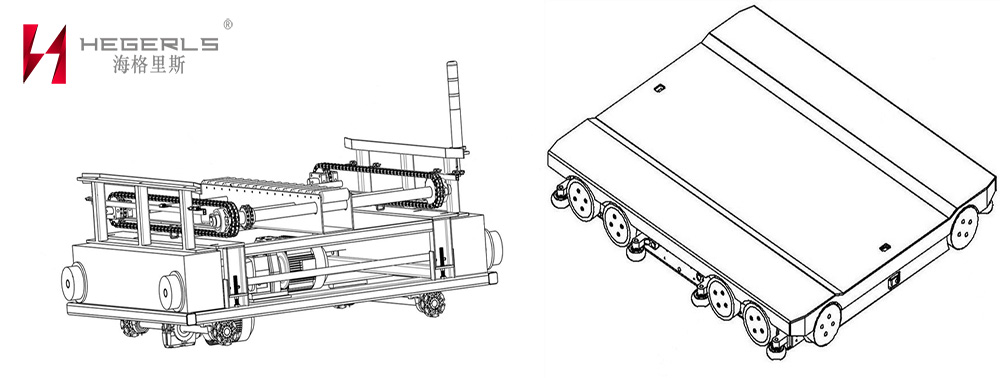

The Hegerls tray four-way shuttle solution is not a simple dense storage system, but a highly flexible and dynamic intelligent warehousing solution. Its core advantage lies in discrete devices and distributed control, allowing users and enterprises to flexibly combine and deploy as needed like building blocks. Unlike AS/RS stacker cranes that can only operate on fixed paths, the four-way vehicle system is standardized due to its hardware products, namely the four-way vehicle, which can be replaced with a new car at any time in case of failure. Secondly, flexibility is reflected in the "dynamic scalability" of the entire system. User enterprises can increase or decrease the number of four-way vehicles at any time according to changes such as off peak seasons and business growth, improving the system's carrying capacity. This means that major enterprises can flexibly configure the number of four-way shuttle cars according to their needs and schedule their efficient operation through software. The maximum no-load speed of 2m/s, the speed of changing tracks in 3s, and the excellent operating parameters combined with a self-developed new controller greatly improve the efficiency of vehicle operation. The Hebei Woke HEGERLS intelligent control system provides strong and powerful software support for "human-machine object" cluster scheduling and efficient collaboration, ensuring the efficient deployment of multiple vehicles and devices in multi-layer tasks.

The Hebei Woke HEGERLS intelligent tray four-way vehicle system is designed based on "hardware standardization" and "software modularization", which has advantages such as high-density storage, strong site adaptability, flexible expansion, and short delivery cycle. Of course, different types of solutions have their own scope of application, and users of various small and medium-sized enterprises should also choose appropriate intelligent automated warehousing warehouses based on their actual situation.

Post time: Dec-12-2023