With the rapid development of e-commerce and intelligent manufacturing technology, the demand for integration of multiple systems such as automated warehousing, intensive warehousing, automatic handling systems, automatic identification, wireless communication, etc. is also increasing. The technology of logistics equipment system intensification, automation, intelligence, etc. is also constantly improving. The advantages of dense storage technology are high space availability, efficient operation mode, fewer staff, and large storage capacity. The emergence of the HEGERLS pallet four-way shuttle provides a new logistics solution for high-density automated warehousing. The HEGERLS pallet four-way vehicle solution is not a simple dense storage system, but a highly flexible and dynamic intelligent warehousing solution. Its core advantage lies in discrete devices and distributed control, which means that customers can flexibly configure the number of four-way vehicles according to their needs and schedule their efficient operation through software.

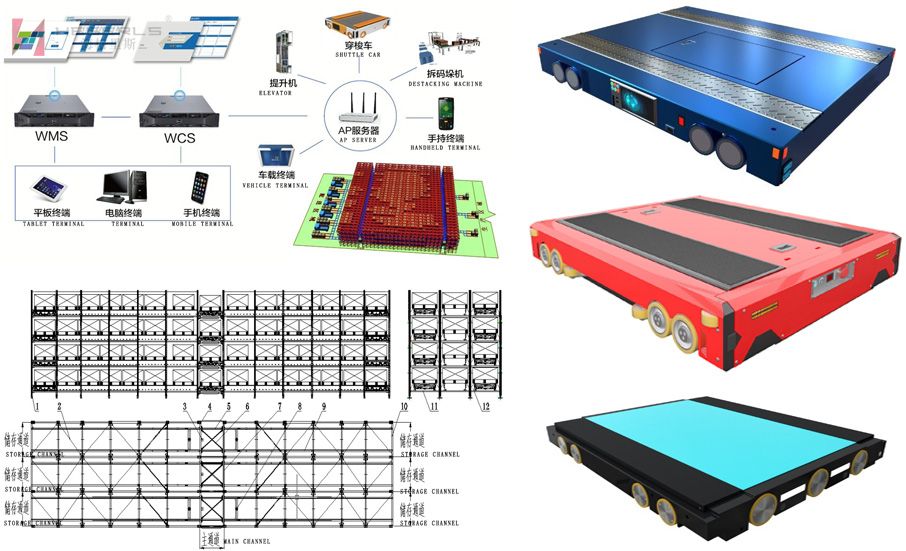

The shuttle shelf system, combined with a tray four-way shuttle system and a dedicated vertical lifting and transportation storage system, is called a tray four-way shuttle automated dense storage system. It consists of WMS, WCS, wireless base station AP, servers and terminals, multi-layer shelves and their surrounding equipment, etc. The tray four-way shuttle automated dense storage system is composed of a shuttle truck body that implements four-way logistics operations in the same level work roadway based on work instructions, It can achieve storage scheduling and management of any storage location on the same layer, combined with lifting machines to achieve intelligent shuttle bike or storage item leveling operations, in order to achieve three-dimensional dynamic storage management of storage units in the entire storage area. It is an upgrade and replacement of shuttle type warehouse construction and transformation, and also one of the ideal logistics forms for intelligent shuttle dense storage; The management and control information system of the tray four way shuttle type automated dense storage system is responsible for monitoring and scheduling the operational status of the internal equipment of the entire shelf system. The quantity ratio and deployment position of the pallet four-way shuttle and vertical elevator in the shelf system are determined by operational requirements (operational efficiency, inbound and outbound methods) and can be dynamically adjusted. The storage space of the shelves is connected by the storage lane track, and the storage lanes within a single shelf layer are connected by the main track. The main track between each shelf layer is connected by a vertical elevator, and all connected tracks form a rail transit network. In this transportation network, it includes facilities and equipment such as storage locations, storage tracks, main tracks, vertical elevators, and shelf ports. The storage locations are located on the storage tracks, and both the storage locations and storage tracks are located in the storage tunnels. In a storage tunnel, the storage tunnel track connects multiple cargo locations to form a cargo compartment. If both ends of the storage tunnel can access goods, it can also be divided into two adjacent cargo compartments from a certain point in the middle of the storage tunnel.

The HEGERLS pallet type four-way vehicle adopts a combination of uniform and robust design, optimizing the mechanical structure, and using polyurethane as the wheel material. Because polyurethane has advantages such as high cutting resistance, high wear resistance, excellent chemical resistance, and oil resistance, the entire vehicle body needs to have sufficient strength and compression resistance, not easy to deform, in order to achieve low energy consumption, high efficiency, reliable and stable operation of shuttle cars; Adopting multi-level hardware and software monitoring measures, setting safe operating distances and judgment principles, and ensuring the safe operation of the entire vehicle through specific operating limit blockers or anti overturning mechanisms. Under the command of CNC barcode technology application and real-time monitoring and scheduling information management system, multi vehicle collaborative operation can be achieved; The tray four-way shuttle is efficient, precise, intelligent scheduling, clean and low noise, and flexible in configuration. It can operate normally in various complex working conditions such as high-temperature and low-temperature storage environments. The mechanical structure is the foundation and fundamental guarantee for the realization of various functions of the pallet four-way shuttle vehicle. The rationality of the structural design will have an impact on the smoothness and flexibility of the vehicle’s operation, the accuracy of running positioning, and the friendliness of human-machine interaction.

The Hebei Woke HEGERLS pallet four-way shuttle adopts imported servo drivers combined with high speed and high torque servo motors, and outputs driving force through a two-stage reduction mechanism, with excellent response speed and driving speed. The Hebei Woke HEGERLS pallet four-way shuttle can calmly cope with the material inventory needs of handling, storage, and dense shelves in various complex scenarios, greatly improving the flexibility of scheduling and achieving optimization of efficiency, cost, and resources.

The Hebei Woke HEGERLS pallet four-way shuttle not only continues the excellent accuracy of Hebei Woke’s intelligent products, but also features multiple imported large brand sensors such as calibration, obstacle avoidance, and cargo detection, with a driving positioning accuracy of ± 2mm. It also adopts low-temperature circuit processing technology and built-in phosphoric acid/lithium titanate batteries, making the product capable of fast charging and longer endurance, and can continue to operate at room temperature, cold storage, or frozen environments, Suitable for different vertical industries and segmented scenarios.

The reason why Hebei Woke collectively refers to the tray four-way shuttle system as the “new generation tray flexible logistics solution” is mainly because it has two major characteristics: discrete equipment and distributed control. Users and enterprises can flexibly combine and deploy as needed, just like building blocks. Unlike AS/RS stackers, which can only operate on fixed paths, the four-way vehicle system is standardized due to its hardware product, which can be replaced with a new car at any time in the event of a malfunction. Secondly, flexibility is reflected in the “dynamic scalability” of the entire system, where users and enterprises can increase or decrease the number of four-way vehicles at any time according to changes such as off-season and business growth, improving the system’s carrying capacity.

Hebei Woke Metal Products Co., Ltd., after years of technological updates and practice, has greatly improved the speed, efficiency, and reliability of the HEGERLS pallet four-way shuttle car. It has good compatibility and matching with automated tunnel stackers, elevators, etc., ensuring the high reliability, operational efficiency, and quality of the overall selection system; The selection or construction of a three-dimensional warehouse for the main logistics process needs to be determined based on factors such as the specific needs of customers, regions, geographical environment and operational environment, investment and operational costs, operational efficiency, supplier qualifications and the quality of completing actual cases, and the reliability of the selected system.

Post time: May-18-2023