With the rapid development of technology, the warehousing and logistics industry has slowly developed towards unmanned, automated, and intelligent directions, and the demand for users has also been increasing day by day. Automated three-dimensional warehouses have already become the standard configuration for many enterprise intelligent warehouses, which can achieve high-level rationalization, automated access, and simplified operation of warehouses. In a three-dimensional warehouse, high-level shelves, combined with intelligent storage equipment such as shuttle cars and stackers, can achieve fully automatic operation of goods entering and leaving the warehouse. In the three-dimensional warehouse of four-way shuttle cars, high-precision guide rails are installed on traditional shelves, allowing the shuttle cars to freely traverse the shelves and be responsible for the transportation of goods; The guide rail has the functions of transporting and storing goods, greatly improving the utilization of storage space

and making dense storage possible. In the three-dimensional warehouse of the four-way shuttle car, the layer changing operation of the shuttle car is another key part of the three-dimensional warehouse system, which is completed by the elevator.

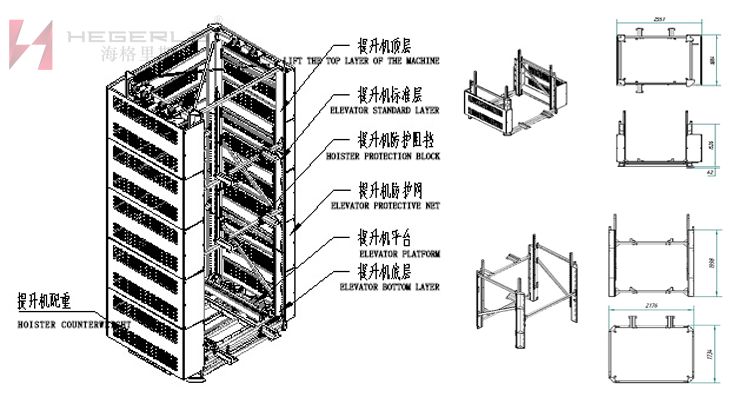

The high-precision lifting machine for the application of four-way shuttle robot belongs to a new type of conveying equipment, mainly used for lifting and conveying goods and changing layers of intelligent four-way shuttle vehicles. It can continuously and vertically transport materials, allowing continuous conveyors at different heights to maintain uninterrupted material transportation. Hebei Woke Metal Products Co., Ltd. has independently developed a standard high-precision shuttle car application lifting machine.

The Hebei Woke HEGERLS four-way shuttle car elevator includes a main frame, a counterweight device installed inside the main frame, and a car body. The top of the main frame is fixedly equipped with a top guide mechanism, and the top of the main frame is equipped with a lifting mechanism that drives the counterweight device and the car body to lift. The lifting mechanism includes a reduction motor and a linkage shaft, and the output ends of both sides of the linkage shaft are fixedly connected with driving gears. The lifting device installed on the top of the main body of the car not only facilitates technical workers to quickly inspect the lifting device on the car body during daily maintenance, but also cooperates with the guide gear rack. When the car body is lifted and lowered inside the main frame, it can be smoothly adjusted up and down. The two ends of the top of the car body not only rotate through the

meshing of the guide gear rack and the driving gear, Improve the stability of the lift car body during lifting and lowering. When the shuttle needs to switch between different cargo levels, the shuttle first drives into the cargo platform of the layer changing elevator, which completes the lifting or lowering work under the control of the system.

In practical applications, there are two types of operation modes for elevators: operation with or without a vehicle. When working without a car, the elevator only lifts the cargo unit. When working with a car, the small car and the cargo enter the elevator at the same time, and there is actually no need to change the layer of the elevator. Obviously, when lifting without a car, each layer requires a cargo transfer workstation, which is quite expensive in terms of cost; When working with a car, the system is much simpler, and the ends of each layer are also much simpler, but the efficiency is also much lower, which is also worth noting.

The Hebei Woke HEGERLS four-way shuttle car elevator lifts the goods to the corresponding height through the lifting platform, and then the intelligent four-way shuttle car transports the goods to the designated cargo location. The use of lifting machines eliminates the need for traditional high-altitude forklifts to pick up and place goods in warehouses. The space in the forklift roadway has been transformed into a storage space for automated dense warehouses, greatly improving the utilization rate of storage space in dense warehouses. The hoist can be equipped with protective rolling shutters or shafts to meet the requirements of insulation and crossing fire zones within the warehouse area.

HEGERLS Four Way Shuttle Booster Performance Advantages:

1) By installing a lifting device and a guide rack that meshes with the lifting device on the top of the main frame, and a lifting device on the top of the car body, it is more convenient for technical workers to quickly inspect the lifting device on the car body during daily maintenance;

2) The lifting device and the guide rack cooperate with each other. When the main body of the car is lifted and lowered inside the main frame, the driving gears on both ends of the lifting device that mesh with the guide rack can be smoothly adjusted up and down during the lifting of the car main body. The top two ends of the car main body not only rotate through the meshing of the guide rack and the driving gear, but also improve the stability of the car main body's lifting and lowering;

3) The four auxiliary guide wheels on the top of the main body of the car slide and connect with the wall surface adjacent to the teeth on the adjacent guide rack, playing a guiding and positioning role in the lifting of the main body of the car. The four auxiliary guide wheels also support and assist the four driving gears, reducing the squeezing force when the guide rack and driving gear mesh and rotate. The interior of the main body of the car can stably and smoothly lift during heavy load shuttle vehicles, There will be no shaking, improving the safety of the transportation of the main body of the lift car's heavy-duty shuttle vehicle;

4) The lifting device is fixed inside the base of the fixed frame through the threads of fasteners, making it convenient to fix the lifting device;

5) Prevent the car body from colliding with the ground at the lowest point of landing inside the main frame, and provide a buffering effect between the car body and the ground inside the main frame;

6) By setting a protective baffle at the bottom of the car main body, the protective baffle can limit and fix the protective pad at the bottom of the car main body, so as to prevent the protective pad from falling to the lowest end in the main body frame, and the protective pad from being collided and having a position deviation or falling off from the bottom of the car main body, and at the same time, the protective baffle extends inside the car main body, which can clamp and fix the shuttle machine inside the car main body;

7) By installing an anti-collision component at the lower end of the top guide mechanism, when the car body moves to the top with the cooperation of the lifting component and the guide rack, the top of the car body will first undergo elastic compression with four sets of spring columns to slow down the rising speed of the car body;

8) By setting two sets of parallel distributed limit long rods on the outer side of the main frame, the upward and downward moving counterweight device can achieve directional sliding effect, avoiding the occurrence of deviation and collision between the counterweight device and the main frame or the inner wall of the elevator shaft during lifting operations.

Hebei Woke HEGERLS is a high-tech enterprise with independent design, development, and manufacturing capabilities for three-dimensional warehouse equipment such as stackers, shuttle cars, elevators, and conveyor systems. It is a professional manufacturer of automated three-dimensional warehouses and can provide professional and efficient four-way shuttle car solutions for enterprises. Relevant project cases are spread throughout the country, covering many industries such as chemical, food, machinery, cold storage, new energy, environmental protection, aviation, etc.

Post time: Jun-26-2023