With the accelerated development and continuous iteration of the warehousing and logistics industry, more and more demand for subdivisions has emerged, and higher requirements for the efficiency of warehousing robots have also been put forward. Thus, HEGERLS has been continuously innovating products and warehouse applications according to market demands from “shelf to person” picking scheme to “container to person” storage robot equipment, storage robot shelves, storage robot warehouse solutions, etc. of bin robots.

In recent years, Hebei Walker Metal Products Co., Ltd. (main brand: HEGERLS) and Hairou Innovation Co., Ltd. have negotiated a series of cooperation on products in business work, committed to providing efficient, intelligent, flexible and customized warehousing automation solutions through robot technology and artificial intelligence algorithms, and creating value for each factory and logistics warehouse. By focusing on the R&D and design of the box storage robot system, the independent R&D coverage of core elements such as the robot body, the underlying positioning algorithm, the control system, the robot scheduling, and the intelligent storage management system has been achieved, and the patent layout at home and abroad has been carried out.

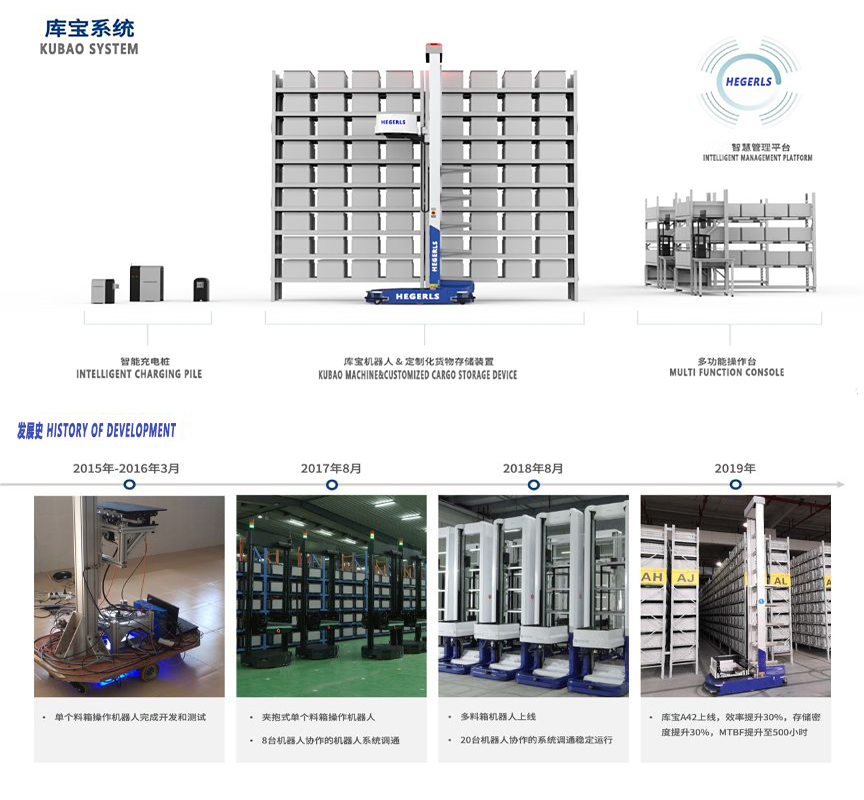

HAIPICK has been upgraded to the fourth generation. It is the first box type warehousing robot system developed and put into commercial use. It can help the warehouse to carry out automatic management, realize intelligent handling, picking and sorting, and accept customized requirements. At present, it has been applied to 500+projects at home and abroad, widely used in footwear, 3PL, e-commerce, power, 3C manufacturing, medicine, retail and other industries, with multiple scenarios. With the Kubao system, customers can realize warehouse automation transformation within one week, increase the storage density by 80% – 400%, and improve the working efficiency of workers by 3-4 times.

Recently, the HAIPICK intelligent robot solution of Kubao robot released by HEGERLS has realized a better combination of “intensive storage+goods to people picking” through the combination of efficient, high storage and high stability intelligent bin robots and small, lightweight, efficient, flexible and cost-effective intelligent vehicle handling robots, It effectively solves the pain point of low manual operation efficiency of “picking and sorting and massive SKU returns” under the requirement of “ultra-high inbound and outbound flow”. The innovation, practicality and representativeness of this solution have been unanimously recognized and favored by application customers.

At present, HAIPICK intelligent robot of Kubao robot released by HEGERLS includes: carton picking robot HEGERLS A42N, lifting picking robot HEGERLS A3, double depth bin robot HEGERLS A42D, telescopic lifting bin robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42M SLAM, multi-layer bin robot HEGERLS A42, dynamic width adjusting bin robot HEGERLS A42-FW, etc.

The design concept of HEGERLS bin robot:

Through the combination mode of “bin robot+one layer cache+vehicle handling robot (namely,” carrying trolley “), the low labor efficiency pain points in business scenarios such as” 3000-10000 bin/hour processing capacity “such as sorting are effectively solved. The main idea of HEGERLS bin robot solution is to divide the work and make the best use of everything, namely:

» Use high cost bin robots to concentrate on “building”;

» Concentrate on “moving bricks” with ultra-low cost handling robots;

» Bring customers higher output and more efficient warehousing solutions with lower costs.

5 highlights of HEGERLS bin robot:

1) The vehicle handling robot has a compact design, simple and reliable structure, smaller channel space, and more flexible system scheduling; The cost is lower, which is only about 20% of the cost of conventional bin robots.

2) The vehicle handling robot has the climbing ability, can carry the material box to climb to the workstation, and the picking height is about 800mm (the height can be flexibly adjusted to adapt to the picking operation). It can pick goods at a fixed position that conforms to the ergonomic height, and the operation is simple, efficient and convenient.

3) The bin robot is responsible for the “up and down picking and placing” in the vertical direction, and the transport trolley is responsible for the “long distance transport of bin” in the horizontal direction. The bin robot and the carrying trolley are handed over to each other through the buffer position. The two robots do not affect each other and maximize the use efficiency.

4) In the high rack intensive storage area, the first floor of the storage space is transformed into half of the buffer space and half of the channel. The empty car can pass under the buffer space and the loaded car can pass through the channel.

5) The hopper robot adopts the “single gripping” mode, cancels the rotating mechanism, and adopts the third generation robot universal chassis independently developed by HEGERLS. The overall structure is very simple, the cost is only about 60% of the conventional hopper robot, but the single machine efficiency is improved by 100%.

In addition to bin storage robots, picking workstations, etc., HEGERLS can provide customers with a complete set of storage management systems – intelligent management platform, which includes IWMS intelligent storage management system, ESS equipment scheduling management system, RCS robot control system, which can interface with customers’ MES, ERP and other software systems, and can interface with Kubao robots, industrial mechanical arms, unmanned forklifts and other automation equipment, Form a complete set of Kubao robot system.

Post time: Nov-01-2022