Compared with previous logistics automation solutions, we can see that it is mainly concentrated in the scenario of box type. With the economic development of today’s society, people’s living needs and the rising trend of overall consumption, the demand for pallet solutions is greater. Thus, storage, handling and whole box picking constitute the requirements of pallet application. The four-way pallet car system can be applied to different vertical industries and segmentation scenarios. With the rapid promotion of automated and intelligent logistics technology, can the four-way pallet car system achieve a larger market scale?

Hergels believes that the market acceptance of a technology depends not only on its progressiveness, but also on the reliability and maturity of the technology itself. It is the basis for supporting the project. It is easier to be accepted by the market after having a successful case; Secondly, it depends on its economy and whether it can meet the investment income requirements of users.

Hercules Hegels according to the application effect of Hercules Hegels pallet four-way car system by a raw material production enterprise of a strategic partner: when using Hercules Hegels pallet four-way car system, compared with the stacker scheme, under the same area, the space utilization rate can be increased by more than 20%, the pallet cost can be saved by more than 40%, the project implementation cycle can be shortened by more than 50%, the electricity cost can be saved by more than 65%, and the installed capacity can be reduced by more than 65%, Help enterprises to actually reduce operating costs and implement the “cost reduction and efficiency increase”.

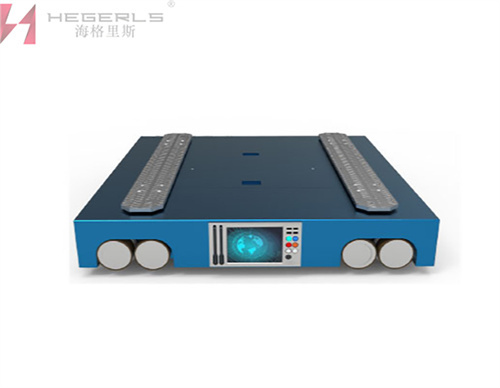

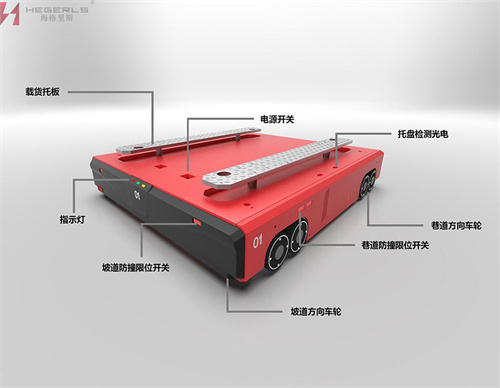

More importantly, the hegerls intelligent pallet four-way vehicle system has strong “warehouse adaptability”. Although the area, size and shape of enterprise user warehouses are different, the requirements for automated logistics systems are the same. How to make the automatic logistics equipment adapt to different warehouses, flexibility and scalability is particularly important. As a discrete device, hegerls intelligent pallet four-way vehicle can realize the whole warehouse in one vehicle. No matter whether the warehouse is concave, convex or irregular bevel, it can make full use of every inch of space in the warehouse and has a very good adaptability to the warehouse.

So the question is, can the four-way pallet system achieve a larger market scale? Hegerls believes that the current application scenario of the pallet four-way vehicle system is far from being fully understood and explored.

1) There are many application scenarios for pallet four-way vehicles

▷ the raw material warehouse, line warehouse, finished product warehouse, etc. of the logistics center and manufacturing center are connected with different machines / production lines, with less reserves and high warehousing efficiency requirements.

▷ intensive storage, especially for businesses with few varieties of goods and large quantities, the warehouse location can be flexibly configured with high utilization rate. This is also the most common application scenario of pallet four-way vehicle system at present.

▷ cache sorting: goods can be delivered from the three-dimensional warehouse in advance. The shuttle car system in the cache area sorts in advance according to the delivery order, and completes the collection in advance before loading, so as to improve the loading efficiency.

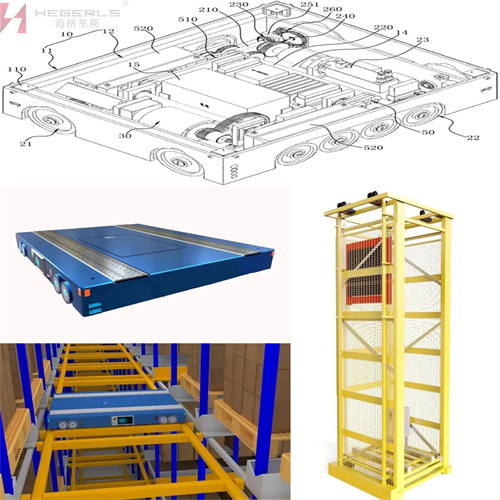

▷ multi storey building, pallet four-way vehicle system can connect the building in the old industrial park up and down to become a modern intelligent warehouse.

▷ cross building connection in the park. The pallet four-way vehicle can be regarded as a mobile robot with tracks, which stores and carries goods between buildings with different functions in the park, so that the warehouse locations between buildings can be shared.

▷ utilization of idle space in molding factories or logistics centers. For example, there is usually a space of five or six meters above the office and production line. The four-way tray system can be combined with the elevator to complete the material transportation, so as to avoid crossing with the ground logistics line, improve the space utilization and save costs.

▷ the space utilization rate of cold storage has a great impact on the cost.

2) Innovative application scenario of pallet four-way vehicle

Of course, in addition to the above numerous application scenarios of pallet four-way cars, haggis herls also launched innovative application scenarios of pallet four-way cars:

▷ hagerls pallet four-way vehicle +amr: four-way vehicle three-dimensional storage +amr ground pallet handling, instead of the “stacker + conveyor line + forklift” scheme, AMR can move goods to the platform, with more flexible system, compact layout, simple logistics equipment, significantly improved space utilization, less total investment and short project implementation cycle.

▷ hegerls pallet four-way Car + visual inventory workstation: Based on computer vision technology, count and inventory pallets; You can take advantage of non working hours such as night time to make an inventory of the whole warehouse without people; Realize the accurate counting of cargo arrival boxes.

▷ hegerls pallet four-way Car + destacking manipulator: four-way car pallet storage + manipulator destacking, realizing fully unmanned full container picking; The same mechanical arm is used for destacking and mixed stacking to directly complete the pallet aggregation of outbound goods; At night, the mechanical arm can be used to merge the pallet with the SKU to improve the space utilization.

▷ hegerls pallet four-way vehicle ++ai vision for automatic loading.

At present, the tray four-way vehicle flexible system scheme has attracted more and more users’ attention, and has begun to be promoted and applied in many industries, such as food, clothing, e-commerce, retail, 3C, medical, tobacco, cold chain, etc. the market demand continues to show, the industry penetration rate increases year by year, and it is expected to usher in rapid growth in the next few years.

Post time: Aug-01-2022