With the rapid popularization of automated warehouse in China, higher requirements have been put forward for the safety, integration, operation efficiency and comprehensive cost of warehouse automation equipment. The four-way shuttle car is a new type of automatic storage equipment that integrates the functions of the traditional mother car and the slave car, and uses one car to realize the functions of the two cars. It has the advantages of high cost performance, high storage density, and high storage utilization. The three-dimensional warehouse based on high space utilization has more strict requirements on the overall dimensions of the four-way shuttle cars running in it. On the premise that the functions are normal and realized, the four-way shuttle cars with thinner thickness can be used to improve the space utilization of the three-dimensional warehouse.

It should be known that the structural design of the existing mechanical four-way shuttle car is complex, and multiple drive structures are arranged in the car body, which makes the four-way shuttle car thicker and cannot further improve the storage capacity of the three-dimensional warehouse. Therefore, today's automated warehouse is developing rapidly in the direction of higher space utilization, faster warehousing efficiency and intelligence, and higher cargo storage density. Under the premise of the same floor area of the warehouse, increasing the number of storeys of the warehouse as much as possible has become the goal of the storage of the three-dimensional warehouse, which has more strict requirements for the size of the four-way shuttle running in it. How to make the four-way shuttle more lightweight has become the key to occupy the leading position in the market.

About HEGERLS

Hebei Walker Metal Products Co., Ltd. (self owned brand: HEGERLS) is a high-tech enterprise of machinery and industrial equipment. With strong technical force, it is a limited liability company. With the development of the market and the demand of production, the company has independently researched and developed, designed, produced, sold, integrated, installed, and commissioned a series of new high-tech products under its own brand HEGERLS, and has been successively awarded the director units of China Storage and Distribution Association, Hebei Modern Logistics Association, Hebei E-Commerce Association, vice president units of Xingtai International Chamber of Commerce, shuttle cars, stackers Mobile shelves and other intelligent automatic logistics storage equipment have won dozens of national patents in technology, won the beauty award of "Made in China" twice, passed the certification of SGS, BV and TUV international product quality inspection institutions, and passed the certification of three major systems of "Quality, Environment and Health" ISO, and won the titles of "China Quality Service Reputation AAAA Brand Enterprise", "National Product Quality Assurance Enterprise", "China Famous Brand Product", etc honor.

HEGERLS series products

Storage shelf: shuttle shelf, cross beam shelf, four-way shuttle car shelf, pallet four-way shuttle car shelf, medium shelf, light shelf, pallet shelf, rotary shelf, through shelf, stereoscopic warehouse shelf, attic shelf, floor shelf, cantilever shelf, mobile shelf, fluent shelf, drive in shelf, gravity shelf, high storage shelf, press in shelf, pick out shelf Narrow aisle type shelf, heavy pallet shelf, shelf type shelf, drawer type shelf, bracket type shelf, multi-layer attic type shelf, stacking type shelf, three-dimensional high level shelf, universal angle steel shelf, corridor type shelf, mold shelf, dense cabinet, steel platform, anti-corrosion shelf, etc.

Storage equipment: steel structure platform, steel pallet, steel material box, smart fixed frame, storage cage, isolation net, elevator, hydraulic pressure, shuttle car, two-way shuttle car, parent shuttle car, four-way shuttle car, stacker, screen partition, climbing car, intelligent transportation and sorting equipment, pallet, electric forklift, container, turnover box, AGV, etc.

New intelligent robot series: Kubao robot series, which includes: carton picking robot HEGERLS A42N, lifting picking robot HEGERLS A3, double depth bin robot HEGERLS A42D, telescopic lifting bin robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42 SLAM, multi-layer bin robot HEGERLS A42, dynamic width adjusting bin robot HEGERLS A42-FW, intelligent management platform, workstation Smart Charge Point.

Automated stereoscopic warehouse: shuttle stereoscopic warehouse, beam stereoscopic warehouse, pallet stereoscopic warehouse, heavy shelf stereoscopic warehouse, automated warehouse stereoscopic warehouse, attic stereoscopic warehouse, layer stereoscopic warehouse, four-way shuttle car stereoscopic warehouse, mobile stereoscopic warehouse, narrow roadway stereoscopic warehouse, unit stereoscopic warehouse, through stereoscopic warehouse, cargo format stereoscopic warehouse, automated cabinet stereoscopic warehouse, strip shelf stereoscopic warehouse, picking stereoscopic warehouse, semi-automatic stereoscopic warehouse Linear guideway stereo warehouse, U-guideway stereo warehouse, traverse guideway stereo warehouse, low floor stereo warehouse, middle floor stereo warehouse, high floor stereo warehouse, integrated stereo warehouse, layered stereo warehouse, stacker stereo warehouse, circulating shelf stereo warehouse, etc.

Warehouse management system: order management system (OMS), warehouse management system (WMS), warehouse control system (WCS) and transportation management system (TMS). The warehouse management system provided by HEGERLS can promote the efficiency improvement and cost reduction of the whole chain, and realize the real "intelligent warehouse configuration integration".

High quality professional product - HEGERLS new light and thin four-way shuttle

The light and thin four-way shuttle can walk in any direction "from front to back, from left to right", and can reach any cargo position in the warehouse through the cooperation with wireless network, software system and elevator. It is a real three-dimensional shuttle. At the same time, the light four-way shuttle can also adapt to various irregular sites, greatly improve the space utilization, and adjust the system capacity by increasing the number of shuttle cars. The intelligent light and thin four-way shuttle car adopts a pure mechanical structure, which is stable and durable. At the same time, it does not need to change hydraulic oil frequently and other maintenance operations, effectively reducing the maintenance cost. It is compatible with the two-way shuttle board shelf, reducing the upgrading cost of the vertical warehouse. The body of the intelligent light and thin four-way shuttle is lighter and thinner. The light and thin four-way shuttle is an intelligent handling device that integrates four-way driving, track change in place, automatic handling, intelligent monitoring and traffic dynamic management.

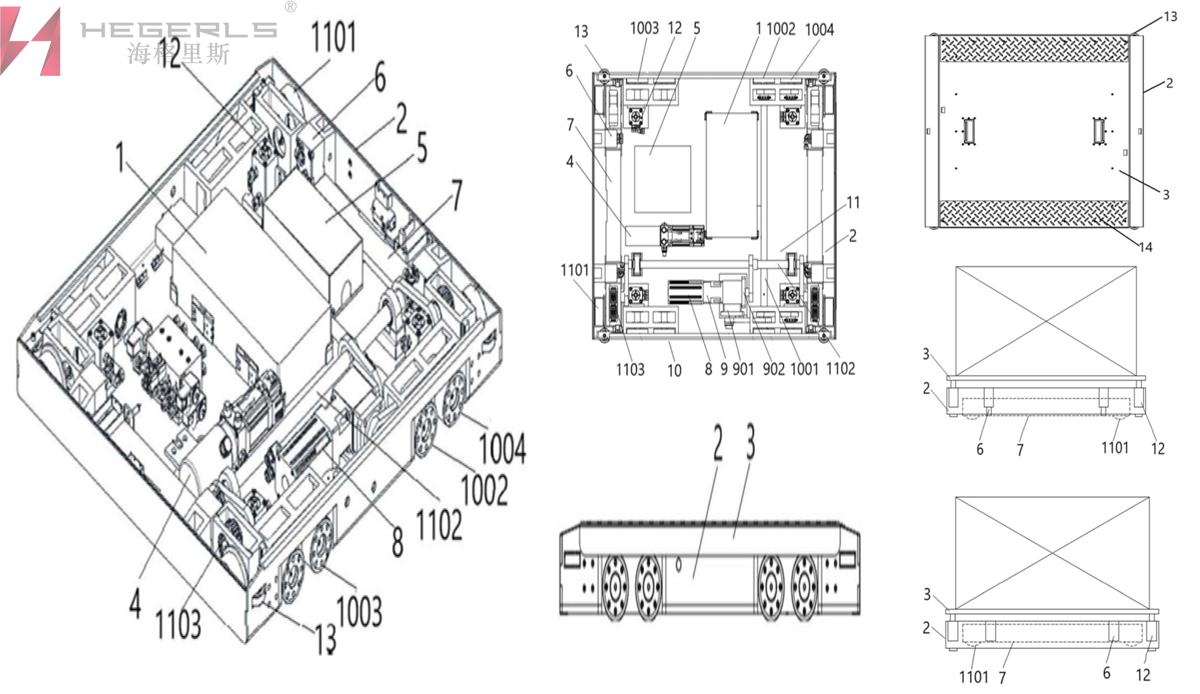

HEGERLS lightweight four-way shuttle structure

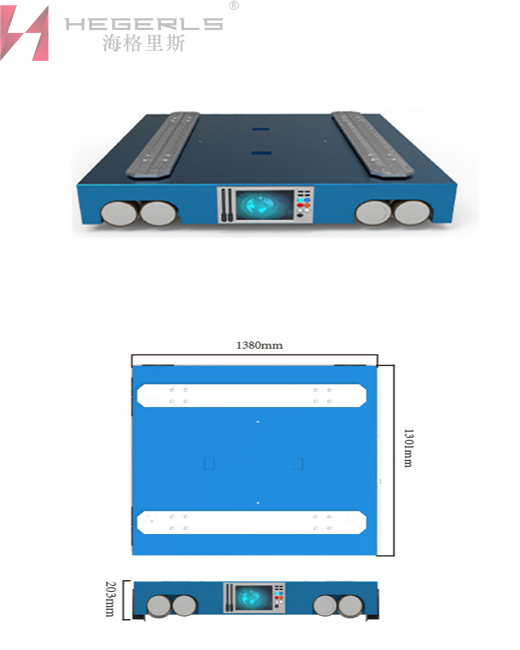

HEGERLS new light and thin four-way shuttle car, including car body and drive motor. The car body is formed by two end plates and two side plates alternately enclosed. The bottom of the car body is set with a bottom plate, and a reserved gap is set between the bottom plate and the end plates on both sides; Four groups of front and rear traveling wheel groups are symmetrically connected between the bottom plate and the end plates on both sides, and four groups of left and right traveling wheel groups are fixed on both sides of the side plate of the car body; The driving motor is arranged on the bottom plate, and is used to drive the front and rear traveling wheel groups and the left and right traveling wheel groups to walk alternately; The vehicle body is also equipped with a fixed hydraulic drive mechanism, which drives the front and rear traveling wheel groups to move up and down through the reserved clearance and drives the tray on the vehicle body to move up and down. The biggest feature of HEGERLS lightweight four-way shuttle structure is that the walking wheel in one direction of the four-way shuttle is set inside the body of the four-way shuttle. On the premise that the functions of the four-way shuttle can be realized, the arrangement of internal components is more reasonable, so that the four-way shuttle can reduce its thickness. The light and thin four-way shuttle car, in which the hydraulic reversing and jacking device reduces the intermediate transmission link, the failure rate will be lower, and the installation and maintenance will be more convenient, which greatly reduces the running noise of the four-way shuttle car; Its hydraulic system has good lifting synchronization and stronger bearing capacity. This is because of the ultra-thin design, which improves the utilization rate of the warehouse, and the four-way shuttle car has a lower walking rail height, which saves the rail materials of the warehouse and better controls the overall storage cost.

Features and advantages of HEGERLS light and thin four-way shuttle

1) Automate work, make management more efficient

HEGERLS light and thin four-way shuttle car replaces manual operation, with maximum acceleration of 1m/s and maximum running speed of 120m/min, and four-way travel is more efficient; Cooperate with the floor changing elevator, cross roadway and cross floor operation, and run the whole warehouse with one car; The ultra-thin model with a dead weight of 300kg and the super capacitor with a 1-hour charge and 8-hour battery life are energy-saving, environment-friendly and efficient.

2) Intelligent operation makes operation easier

With its own HEGERLS operating system, it realizes intelligent management: under the command of the Higelis intelligent logistics cloud platform, multiple vehicles work together to achieve efficient linkage of the warehousing system; According to the requirements of integrated management of software and hardware for multi scene operations, timely feedback the running track and dynamic adjustment, independently optimize and update the walking route, and achieve point-to-point handling and storage.

3) High density storage makes space more valuable

The main track is designed flush with the sub track, with less space reserved for the upper and lower trays and more storage space; The secondary car track has no address label, so it is easy to construct and has low failure rate. Conventional warehouse, special-shaped warehouse, multi column warehouse and low-temperature cold storage are all suitable. One car runs through the whole warehouse, making full use of every inch of space in the warehouse.

4) Modular design ensures safety

High degree of module independence, each car in the system can maintain independent operation without being limited by the fault module, and can be replaced with a new car at any time in case of fault; Each running direction is equipped with obstacle detection, which automatically stops when encountering obstacles, making operation safer; There is no gap in the main track, so the operation is more stable, the noise is less, and the service life of the traveling wheel is longer.

5) Flexible deployment makes the supply chain more casual

As building blocks, customer enterprises can flexibly combine and deploy, and increase or decrease the number of four-way vehicles at any time according to changes in off peak season and business growth, so that the supply chain can be satisfied: in business peak season, multiple cars can be added to increase the system throughput; In the off-season, the number of cars can be reduced to improve system redundancy.

6) Standardize products to optimize costs

The new HEGERLS lightweight four-way shuttle car can flexibly configure the cargo space according to the size and load of materials, and is compatible with pallets of different sizes. The number of equipment can be adjusted according to the warehousing efficiency and density. The cost of warehouse expansion is low, and the implementation cycle is short, so as to maximize the cost, efficiency and resources.

7) Convenient positioning, more accurate operation

Simple positioning mode, no need to install positioning marks in the roadway. The integrated positioning technology of encoder+laser ranging+barcode positioning is adopted, and the positioning accuracy can reach ± 2mm.

Differences between HEGERLS light and thin four-way shuttle car and multi-layer shuttle car system

The multi-layered shuttle car mainly solves the problems of positioning, power supply and communication in the roadway. In addition to the above problems, the HEGERLS lightweight four-way shuttle car can also solve the problems of vehicle avoidance, vehicle scheduling, steering, layer change, especially the path planning problems such as scheduling and avoidance. Therefore, we can see that the technology of light and thin four-way shuttle is more complex. Moreover, the multi-layer shuttle system has the characteristics of low density storage and high speed picking. This kind of shuttle is not suitable for the operation scene with large storage capacity, but more suitable for large-scale rapid picking; The light and thin four-way shuttle system is not only suitable for low flow and high-density storage, but also suitable for high-flow and high-density storage and picking. It can provide a better solution to meet customer needs. In addition, from the height of the warehouse, the low space will lead to the failure of the elevator efficiency for the multi-layer shuttle car. Therefore, the lower limit of the application of the multi-layer shuttle car should not be less than 10 meters, while there is no limit for the lightweight four-way shuttle car.

Post time: Nov-14-2022