In today’s increasingly high operating costs of warehouses, improving space utilization has become an urgent need for warehouses. With the diversification and complexity of logistics business types, the Hebei Woke HEGERLS four-way shuttle has emerged in this emerging automated storage technology and has been widely applied to a certain extent. We can see its existence in many automated warehouses, but as a company purchasing, we often focus on product quality and price issues. So what is the price of a four-way shuttle? What is the quotation for a four way shuttle car?

About the HEGERLS Four Way Shuttle

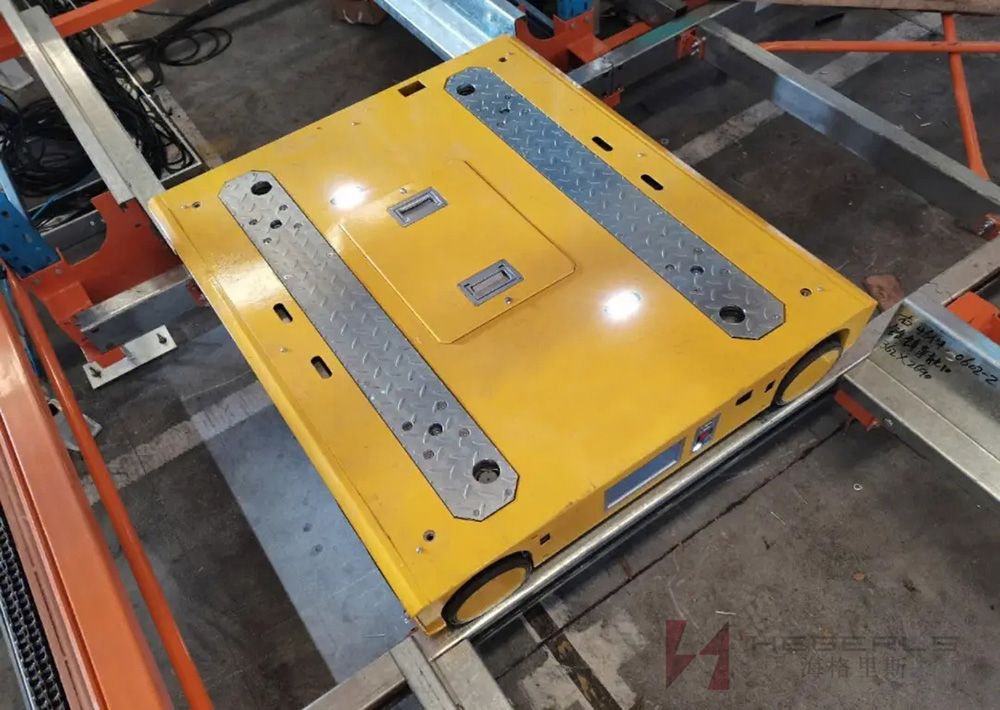

The HEGERLS four-way shuttle adopts a pure mechanical structure, with a long product life cycle. At the same time, it adopts a mechanical lifting design, which eliminates the risk of hydraulic structure sealing ring aging and does not require frequent replacement of hydraulic oil. The maintenance cost is low, and it is more energy-saving and efficient. The four-way shuttle car can be compatible with the two-way shuttle board shelf, reducing the cost of upgrading the intelligent library; At the same time, its automatic dust removal system can adapt to more complex environments. The system consists of Hebei Woke HEGERLS four-way shuttle, fast hoist, horizontal conveying system, shelf system, and WMS/WCS management and control system. Hebei Woke HEGERLS four-way shuttle truck rack system uses computers to carry out accurate information management of cargo information, which reduces the possible errors in the storage of goods and improves work efficiency. At the same time, Hebei Woke HEGERLS four-way shuttle truck rack system realizes automatic operation in the delivery of goods in and out of the warehouse, which is safe and reliable in handling and reduces the damage rate of goods, It is also possible to provide a good storage environment for some goods with special environmental requirements through special designs, while reducing the potential harm to manual labor during warehouse operations, thereby greatly improving the level of safety production management. The Hebei Woke HEGERLS four-way shuttle car can automatically switch in the 90 degree direction between the longitudinal storage lane and the transverse transfer channel. In addition to the characteristics of a general shuttle mother car, it is more suitable for warehouse storage mode in complex terrain environments. This also determines that the four-way shuttle car has a larger application range and greater flexibility, and the system has higher safety and stability. For example, when a small car encounters a problem, the four-way shuttle can freely change the roadway, increase or decrease the number of shuttle cars to adjust without affecting the overall system’s ability to enter and exit the warehouse. Each single machine and unit are interconnected with the support of wireless networks, and under the scheduling of the WMS/WCS upper management and control system, they complement each other to complete the first in, first out or first in, last out inbound and outbound work of goods.

Inventory Principles of Hebei Woke HEGERLS Four Way Shuttle

Place the pallet unit cargo in front of the aisle track of the Hebei Woke HEGERLS four-way shuttle truck rack using a forklift or stacker. Then, warehouse workers use software systems to operate the Hebei Woke HEGERLS four-way shuttle truck to carry the pallet unit on the rack track and transport it to any corresponding cargo location. A Hebei Woke HEGERLS four-way shuttle can be used in multiple rack alleys. The number of HEGERLS four-way shuttle cars in Hebei Woke is determined by a combination of factors such as the depth of the aisle on the shelves, total cargo volume, and frequency of entry and exit. At the same time, through intelligent storage equipment such as elevators, the Hebei Woke HEGERLS four-way shuttle can achieve layer changing and other operations, improving the space utilization rate of the warehouse. The HEGERLS four-way shuttle has fast driving speed, high storage density, strong conveying capacity, and can carry large loads. At the same time, it has a beautiful structure and low operating noise. Not only can it improve logistics efficiency and space utilization, but it can also save manpower and storage area, and is easy to expand.

The Hebei Woke HEGERLS four-way shuttle system is very suitable for dismantling and picking in medical and other industries. It is like a fruit picking system, where a HEGERLS four-way shuttle truck is equivalent to a picking worker. It can complete the picking of multiple order lines in one operation cycle, but the speed is faster, reaching 5m/s, which is five times the efficiency of manual picking operations; At the same time, with the help of precise positioning technology, it saves time in finding cargo spaces; The picking action is also faster. Therefore, overall, a HEGERLS four-way shuttle can achieve a picking workload of 2-3 workers per shift. If calculated as two shifts per 24 hours, it can replace 4-6 workers, undoubtedly having more advantages in terms of economy. The HEGERLS four-way shuttle system, due to its ability to turn, can directly transport raw materials from the warehouse to the production area, making it more economical compared to the general conveyor line+outlet method.

The price issue of four-way shuttle cars is related to various factors, therefore, an exact price range cannot be given. The needs of each enterprise are different, therefore, different specifications, models, and quantities will have different impacts on the price of four-way shuttles. Of course, we should also consider the costs of after-sales service, transportation, and installation.

Hebei Woke Metal Products Co., Ltd. is a comprehensive enterprise dedicated to the planning, design, manufacturing, installation, and consulting services of warehousing and logistics systems and automated three-dimensional warehouse systems. The company adheres to tradition and takes a global perspective, actively introducing and absorbing the advantages and characteristics of advanced logistics equipment structural forms and design ideas, and always occupies a favorable position in the field of warehousing logistics equipment technology. After nearly 20 years of hard work, Hebei Woke Metal Products Co., Ltd. has a team that integrates design, technology, production, installation, and thoughtful sales and after-sales service, accumulating rich experience to provide fully automated intelligent warehousing integrated services for customer groups in various industries.

Hebei Woke Metal Products Co., Ltd. has its own brand: HEGERLS. Hagrid HEGERLS products involve roadway stackers, shuttle cars, mother and child shuttle cars, two way shuttle cars, four way shuttle cars, multi-layer shuttle cars, conveyors, elevators, unmanned handling vehicles AGV, automated sorting systems, three-dimensional warehouse shelves, shuttle shelves, high-level shelves, steel structure attic platforms, steel attic shelves, storage shelves, medium shelves, heavy shelves, crossbeam shelves, corridor shelves Fluent shelves, cantilever shelves, logistics handling equipment, modular containers, parent car systems, management software such as WCS/WMS, and non-standard workstation appliances. In order to meet the needs of international and domestic market competition, continuously improve the company’s quality and environmental management level, and enhance the product quality and environmental management awareness of all employees, Hebei Woke Company strictly operates in accordance with the ISO9001:2000 quality system, ISO14001:2004 environmental system, and ISO10012:2003 measurement system, always pursuing advanced international management models, continuously absorbing advanced technologies from the domestic and foreign logistics industry, and introducing On the basis of digesting advanced foreign technologies and combining with the actual situation of domestic enterprises, independently research and develop new technologies and products. Continuously innovating and advancing, Hebei Woke has always been at a high level in the domestic and international logistics industry.

Post time: May-12-2023