In recent years, with the rapid development of modern manufacturing and production mode transformation, the automated stereoscopic warehouse has its unique advantages such as small floor area, high efficiency and intelligence, and according to the needs of large, medium and small enterprises and the equipment used, the four-way shuttle car stereoscopic warehouse and the stacker stereoscopic warehouse are the two key automated stereoscopic warehouses in common use. Of course, the four-way shuttle car and stacker are also important storage equipment and facilities. At this time, enterprises will encounter such a puzzle: is it better to build a four-way shuttle car warehouse or a stacker warehouse in the warehouse? Which is more suitable for four-way shuttle or stacker?

About Hebei Walker Metal Products Co., Ltd

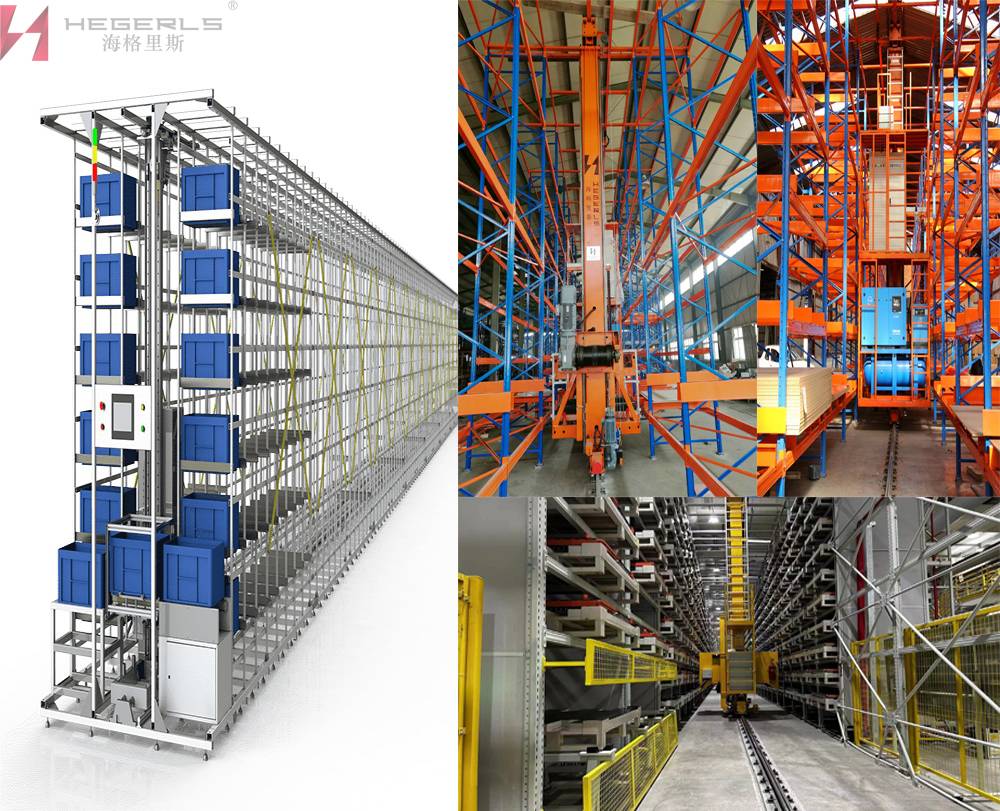

Hebei Walker Metal Products Co., Ltd., formerly known as Guangyuan Shelf Factory, was an earlier company engaged in the shelf industry in North China since 1996. In 1998, it began to participate in the sales and installation of warehousing and logistics equipment. With years of experience in intelligent storage solutions, it has become an advanced enterprise of intelligent storage shelves and intelligent storage equipment at home and abroad. The development strategy of Hebei Walker Metal Products Co., Ltd. is: high-precision shelf business (core business)+integration business (strategic business)+service business (emerging business). As the core business of the company, the high-precision shelf business will, as always, maximize the interests of customers through strict material selection, sophisticated technology and advanced cost control methods. As a strategic business of the company, in terms of products, the company now has advanced technologies such as parent car system, four-way shuttle technology, multi-layer shuttle technology, ground light AGV technology, ground heavy AGV technology, cargo to person picking system, WMS (warehouse management system software), WCS (equipment control software) system, as well as rotary shelf system and light four-way shuttle developed and manufactured in recent years Heavy four-way shuttle car, elevator, stacker, Kubao robot (carton picking robot HEGERLS A42N, lift picking robot HEGERLS A3, double-deep bin robot HEGERLS A42D, telescopic bin lifting robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42M SLAM, multi-layer bin robot HEGERLS A42, etc.), and so on, constantly enrich the variety of automatic stand-alone products, In order to further improve the “shelf+robot=storage system solution”, the independent brand of Hebei Walker is HEGERLS. The series of products and services cover nearly 30 provinces, cities and autonomous regions in China. The products are exported to Europe, the United States, the Middle East, Latin America, Southeast Asia and other countries and regions, and have achieved remarkable results overseas. There are also sales in China, and provide customers with more intelligent and efficient storage solutions. As an emerging business, the service business takes efficiency, informatization, traceability and automation as its core to meet the future market demand of the logistics warehousing center, and provides customers with better added value from the perspective of improving the performance of the equipment system and optimizing customer investment costs.

Hebei Walker Metal Products Co., Ltd. (independent brand: HEGERLS), based on many large, medium and small enterprise project projects undertaken over 20 years, has its own advantages and characteristics for the four-way shuttle car stereo library and stacker stereo library, and the two kinds of automatic stereo library have their own advantages and characteristics, and it is better for enterprises to choose the four-way shuttle car stereo library or the stacker stereo library, This is customized according to the enterprise’s own warehouse and needs.

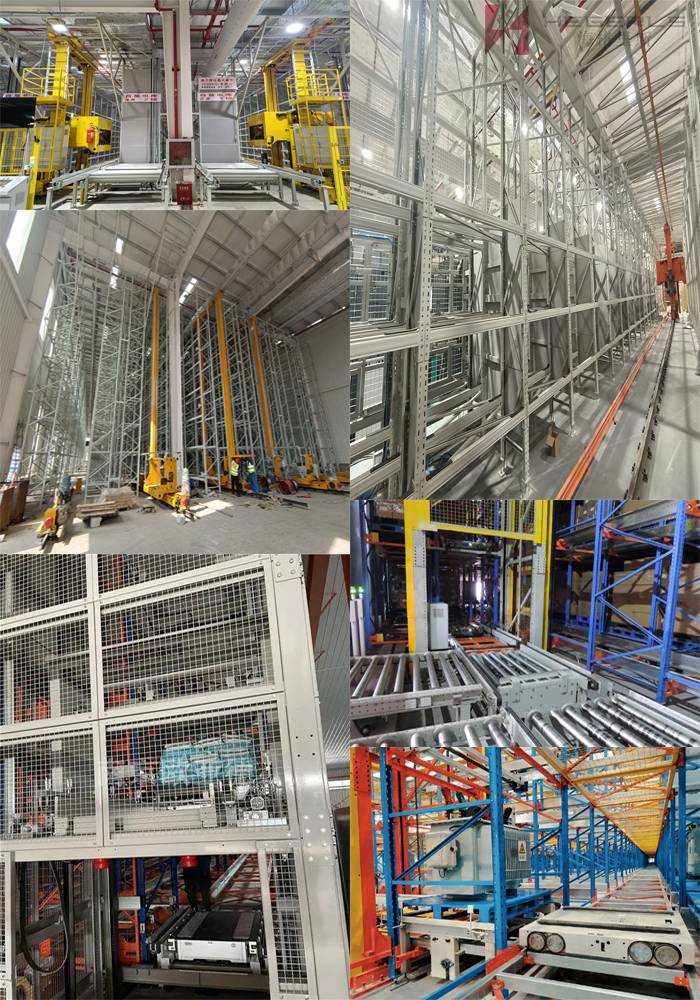

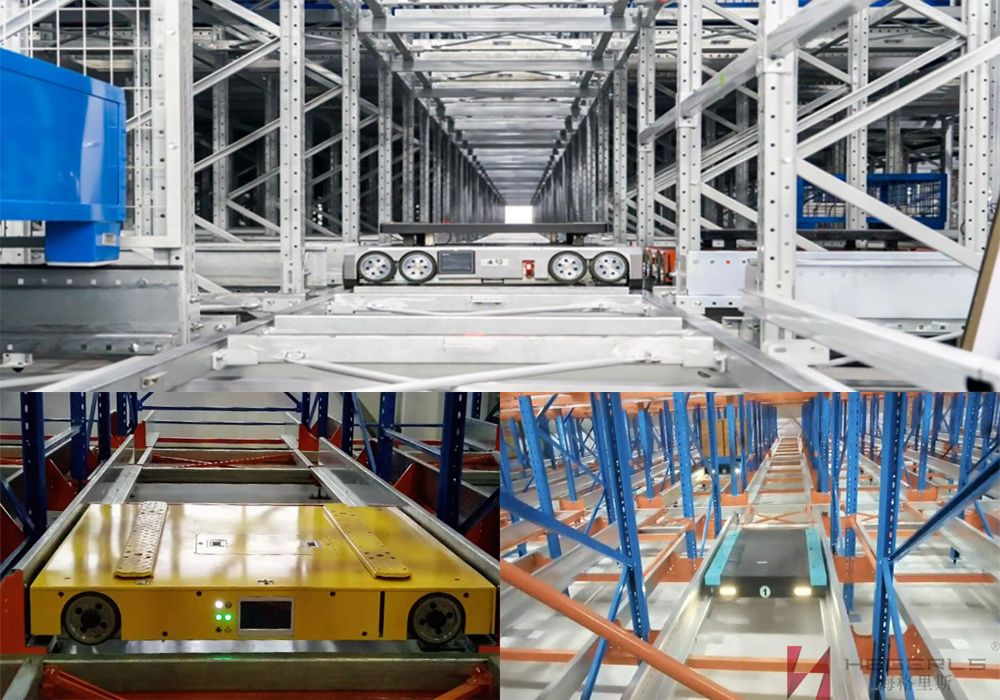

Three-dimensional warehouse of four-way shuttle car

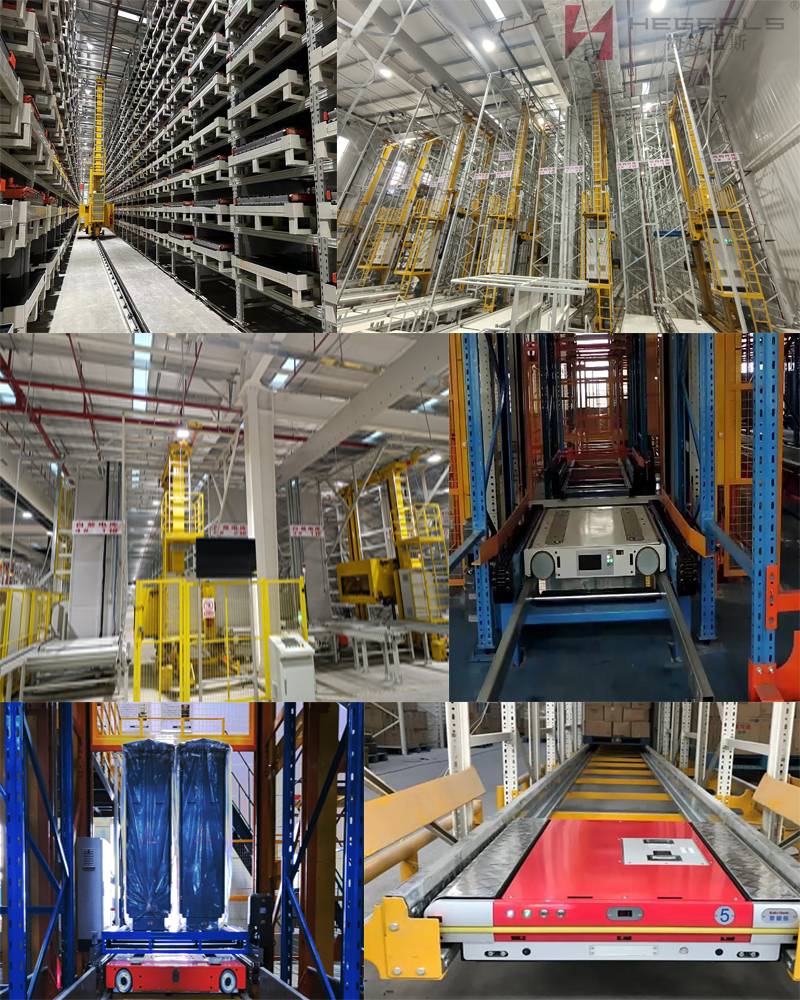

The four-way shuttle car stereoscopic library is composed of dense shelves, four-way shuttle cars, hoists, conveyor lines, WMS, WCS, RCS, etc. Through the shuttle car moving flexibly in the shelves, the goods can be picked and transported. At the same time, the four-way shuttle car stereoscopic library can also achieve first-in, first-out (FIFO) and first-in, first-out (FILO), which is suitable for low-flow, high-density storage, as well as high-flow, high-density storage. The four-way car stereoscopic warehouse has the advantages of flexibility, flexibility and intelligent scheduling. The four-way car can reach any position of the vertical warehouse without space constraints. The product is highly intelligent design, which can automatically carry and transport, automatically store and store goods, and automatically change lanes and layers.

Stacker silo

The stacker stereoscopic warehouse is composed of a narrow channel type high-rise shelf, a stacker, a conveyor line platform and a computer control system. Through the stacker running back and forth in the channel of the stereoscopic warehouse, the goods located at the lane entrance are stored in the rack compartment, or the goods in the compartment are taken out and transported to the lane entrance to complete the operation of goods in and out of the warehouse. In recent years, there are not a few enterprises using stacker stereoscopic warehouse. It is also the mainstream automated three-dimensional warehouse at present. With the roadway stacker as the main stacking and moving equipment, the storage capacity per unit area is far greater than the traditional warehouse. The maximum height of the shelf is equivalent to that of the three-dimensional warehouse. In order to facilitate the access of goods, a stacker is set in the roadway, and the stacker moves along the sky and ground rails in the roadway. With the advantages of high speed, accuracy, stability and data traceability, stacker stereoscopic warehouse has been widely used in tobacco, medical, e-commerce and other industries.

Is it better to choose the stacker or the four-way shuttle system in the three-dimensional warehouse shelves of the enterprise warehouse? HEGERLS will take you to know the difference between the stacker warehouse and the four-way shuttle car warehouse from 12 aspects, so that you can more clearly know how your enterprise will choose in the future, and also help improve the overall storage and transportation efficiency of the goods warehouse.

1、 Applicable scenario

In terms of applicable scenarios, the four-way shuttle car stereoscopic warehouse is generally applicable to warehouses below 20M, and also applicable to multi-pillar and irregular warehouses; The stacker stereoscopic warehouse can be used for higher and longer warehouses, requiring a well-arranged warehouse.

2、 Stacking method

The stacking mode of the four-way shuttle car stereoscopic warehouse and the stacker stereoscopic warehouse is also different. The stacker stereoscopic warehouse is stacked by the automatic narrow channel high shelf; The stacking mode of the four-way shuttle car stereoscopic warehouse is automatic dense high-rise shelves.

3、 Applicable load

Load is also one of the most concerned issues of major enterprises in the automated stereoscopic warehouse. The general rated load of the four-way shuttle stereoscopic warehouse is below 2.0T; The general rated load of the stacker silo is 1T-3T, with a maximum of 8T or higher.

4、 Storage density

The storage density is also the volume ratio of the entire automated stereoscopic warehouse. The four-way shuttle stereoscopic warehouse can be designed according to the type of materials, and its volume ratio can be as high as 40%~60%; Stacker stereoscopic warehouse is generally designed with single depth and double depth, so the volume ratio of goods can generally be as high as 30%~40%.

5、 Operation rate

Whether large enterprises, medium and small enterprises are most concerned about the core issue is that they can improve the efficiency of enterprises at all times, including the efficiency of daily operations. In the automatic stereoscopic warehouse, the four-way shuttle stereoscopic warehouse generally uses multiple equipment for linkage operation, so the overall operation efficiency of the warehouse is generally higher than that of the stacker stereoscopic warehouse by more than 30%; Relatively speaking, the stacker three-dimensional warehouse belongs to the single-machine operation mode, and the stacker efficiency limits the efficiency of the overall warehousing.

6、 Operation noise

Due to the storage facilities in the stacker stereoscopic warehouse, the stacker’s dead weight is relatively large, generally 4-5T, so the noise in the working process is relatively large; The three-dimensional warehouse of four-way shuttle car is different. The storage facilities used by the four-way shuttle car are lithium battery powered, and its weight is relatively light, so the noise is low and the operation is stable.

7、 Energy consumption level

The four-way shuttle cars in the four-way shuttle car stereoscopic warehouse mostly use charging piles for charging, and each four-way car uses a charging pile, the charging power is generally 1.3KW, and the consumption that can complete a single entry/exit is 0.065KW; The stacker used in the three-dimensional warehouse of the stacker is generally powered by sliding contact wire. Each stacker can use three motors, with a charging power of 30KW, and it will consume 0.6KW to complete a single entry/exit.

8、 Anti-risk capability

In terms of anti-risk capability, the four-way shuttle car stereoscopic warehouse is relatively advantageous than the stacker stereoscopic warehouse. When a single machine fails, the entire lane of the stacker stereoscopic warehouse will stop, but all positions of the four-way shuttle car stereoscopic warehouse will not be affected. Other vehicles can be used to push the faulty car out of the lane. At the same time, the four-way shuttle car of other layers can be transferred to the fault layer to continue the work task.

9、 Flexibility

The body of the four-way shuttle car in the three-dimensional warehouse can travel in four directions, and can reach any storage location at the same time. It has strong flexibility, and each vehicle can play a role of mutual support, so as to achieve the optimal configuration; Compared with the stacker, the flexibility is not high. Each stacker can only run on a fixed track, which is very limited.

10、 Late extensibility

Once the overall layout of the warehouse is formed, it is impossible to change, increase or decrease the number of stackers; The four-way shuttle car stereoscopic warehouse is different, and has strong post-expansion. It can increase the number of four-way shuttle cars and other parameters, expand the shelves and other forms according to the post-demand, so as to carry out the second-phase construction of the automated warehouse.

11、 Safety protection

In fact, the four-way shuttle stereoscopic warehouse and the stacker stereoscopic warehouse have high security, but they are slightly different. The four-way shuttle runs smoothly, and the vehicle body adopts various safety measures, such as fire protection design and smoke and temperature alarm design, so it will not easily cause safety accidents; Of course, there will be no safety accidents in the three-dimensional warehouse of the stacker, because the power supply of the stacker is the sliding contact line, and there is a fixed track.

12、 Project investment cost

The construction cost of the stacker stereoscopic warehouse is relatively high, the number of storage locations is small, and the average cost of a single storage location is high; For the four-way shuttle, the investment cost of the project is relatively low, and the average cost of a single cargo space is generally lower than 30% of the stacker.

It can be seen that as a traditional intelligent storage mode, the stacker has entered the market earlier and has the advantages of mature experience. However, with the continuous innovation and development of technology, with the advantages of flexibility, efficiency, density, intelligence and energy saving, the four-way shuttle has gradually become the mainstream, and its advantages have become increasingly prominent. In the actual warehouse construction and reconstruction project, it is also necessary to select the most appropriate solution according to local conditions and multiple factors.

Post time: Feb-10-2023