Project Name: Fuding White Tea Enterprise Four way Shuttle Vehicle Stereoscopic Warehouse Engineering Project

Project cooperation client: A certain white tea enterprise in Fuding

Project construction time: March 2024

Project construction location: Fuding, Ningde City, Fujian Province, China

Design and construction unit: Hebei Woke Metal Products Co., Ltd. (independent brand: Hegerls)

Cooperative customer needs:

This customer is a white tea enterprise in Fujian Province. In order to solve the pain points of traditional low storage capacity, insufficient storage space for capacity expansion, improper picking methods, and inability to timely and accurately deliver materials to the production line, an automated three-dimensional warehouse needs to be built. The existing material stacking warehouse needs to be upgraded and transformed into a four-way shuttle vehicle three-dimensional warehouse, expanding storage space upwards. After multiple comparative investigations, our company was ultimately chosen.

In response to this cooperation project, our company dispatched the project leader, Manager Chen, to the enterprise for on-site inspection. After arriving at the site, we conducted survey and measurement, and provided customers with site planning, scheme design, appropriate shelf selection, storage equipment, and recommended storage management systems. Based on the actual data of the company’s product raw material characteristics, warehouse location, etc., after discussing with the design team and also communicating with the customer to confirm the plan, it was decided to provide the company with a four-way shuttle car three-dimensional warehouse room temperature storage solution.

Project solution:

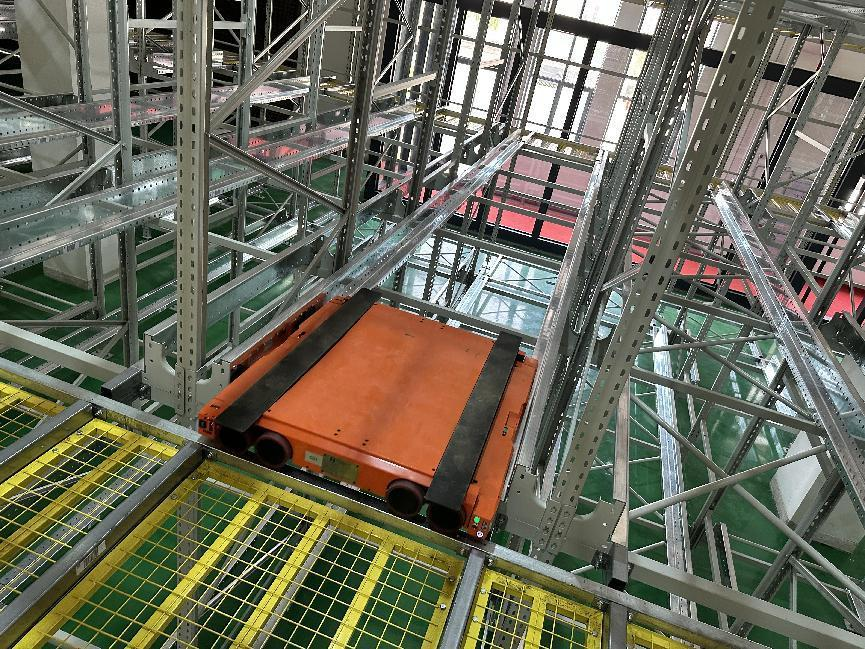

In the operation process of a warehouse, it is generally pursued to store more goods and improve the space utilization rate of the warehouse. Intensive warehousing will become the preferred solution for warehouse design at the beginning. However, when high-density storage warehouses store a large amount of goods, they may encounter problems such as inability to perform first in, first out, and inconvenient picking and turnover, making it difficult to support high-speed outbound efficiency requirements. The intelligent solution for the three-dimensional warehouse of the four-way shuttle car is an intelligent high-density storage rack system. The four-way shuttle car can run on the horizontal and vertical tracks of the rack, and the horizontal movement and storage of goods can be completed by a single device to reach any storage location (or conveying location). Combined with the layer change of the elevator, the automation level of the rack system is greatly improved. It is a new generation of intelligent rack storage system with great application potential.

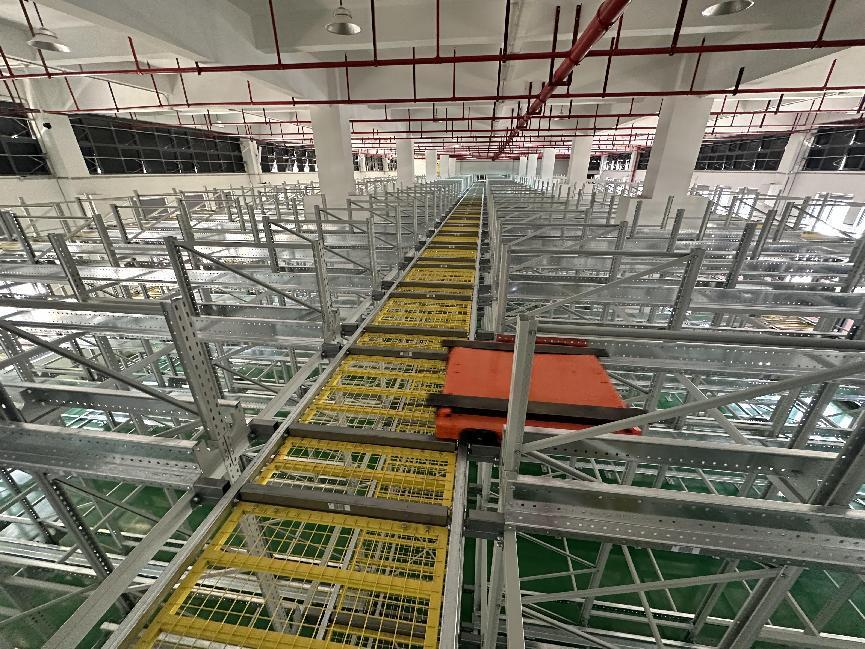

The project mainly adopts the Hegerls four-way shuttle vehicle dense storage system. Due to the warehouse occupying an area of 1600 square meters, it is necessary to deploy and build a 3-layer three-dimensional warehouse with 1155 storage positions, equipped with 2 four-way shuttle vehicles and 2 reciprocating elevators. In collaboration with the IWMS/IWCS intelligent warehousing software, through multi-path planning, the optimal path is intelligently selected to achieve automated access, in and out storage of materials, while improving functions in storage capacity, operation efficiency, damage rate, cost reduction and efficiency increase, and precise management.

The four-way vehicle three-dimensional storage solution is applied to the customer’s existing site, which can not only achieve a dual increase in reserves and production capacity, but also meet the current production needs of the enterprise. At the same time, the design of 24-hour homework also reserves space for future development. The flexible and high-density storage characteristics in this plan also provide diversified and highly compatible choices for various industries to promote intelligent transformation and upgrading!

Project construction site:

For many years, Hebei Woke has focused on the research and development, design, and production delivery of pallet storage robots. It has full value chain research and development capabilities in robot ontology, business systems, core algorithms, and delivery systems. It has accumulated knowledge and implementation experience in multiple industries such as food, cold chain, manufacturing, power, new energy, mechanical manufacturing, and 3C electronics. In the future, it will continue to rely on the dual wheel drive of “product” and “service”, highly combining customer actual needs to provide optimal storage solutions, and creating more value for customers.

Post time: May-07-2024