Stereoscopic warehouse is an important logistics node in modern logistics system, and its application in logistics center is becoming more and more common. At present, the highest three-dimensional warehouse can be as high as 50m, and the storage capacity per unit area of the three-dimensional warehouse can be as high as 7.5 (t/ ㎡), which is 5~10 times that of the ordinary warehouse. Due to the use of high-rise shelves to store goods, the storage area can be developed to a high altitude by a large margin, making full use of the warehouse floor and space. Therefore, the inventory floor area is saved and the space utilization rate is improved. The use of mechanical and automatic equipment can speed up the operation and processing, improve the labor productivity and reduce the labor intensity of operators. Of course, with the demand of modern people and the continuous advanced development of warehousing, automated three-dimensional warehouse has developed into the highest stage of contemporary shelf storage system. It is called the three symbols of logistics technology modernization together with automatic sorting system and automatic guide vehicle.

Stereoscopic warehouse is an important logistics node in modern logistics system, and its application in logistics center is becoming more and more common. At present, the highest three-dimensional warehouse can be as high as 50m, and the storage capacity per unit area of the three-dimensional warehouse can be as high as 7.5 (t/ ㎡), which is 5~10 times that of the ordinary warehouse. Due to the use of high-rise shelves to store goods, the storage area can be developed to a high altitude by a large margin, making full use of the warehouse floor and space. Therefore, the inventory floor area is saved and the space utilization rate is improved. The use of mechanical and automatic equipment can speed up the operation and processing, improve the labor productivity and reduce the labor intensity of operators. Of course, with the demand of modern people and the continuous advanced development of warehousing, automated three-dimensional warehouse has developed into the highest stage of contemporary shelf storage system. It is called the three symbols of logistics technology modernization together with automatic sorting system and automatic guide vehicle.

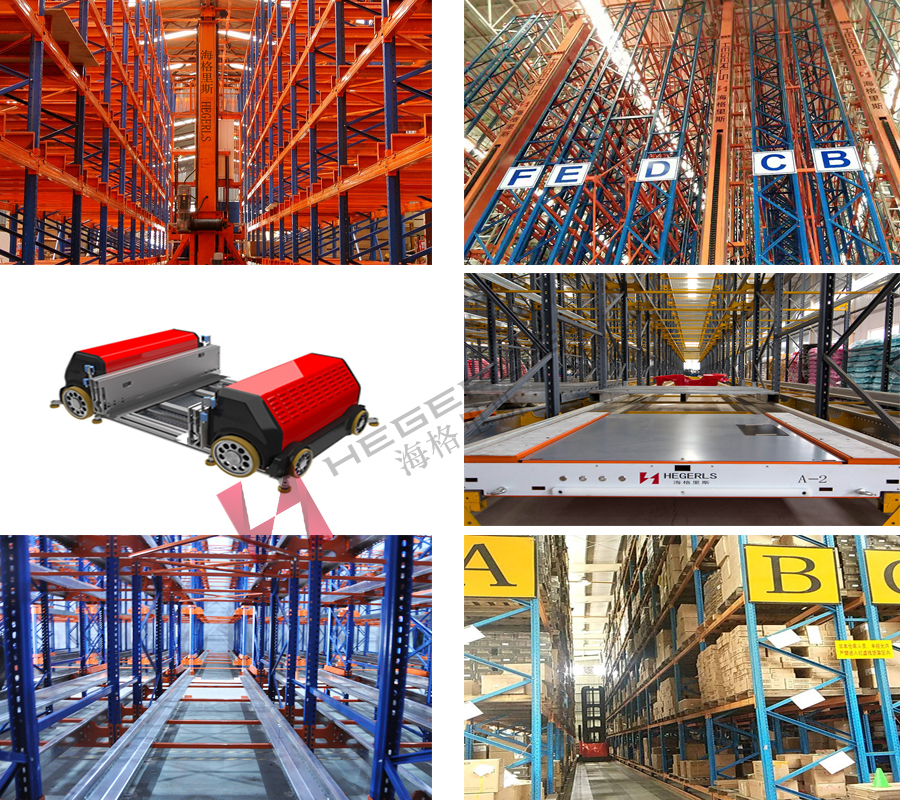

Three dimensional warehouse mainly refers to a warehouse that uses high-rise shelves to store goods in containers or pallets, and uses roadway Stacking Cranes and other machinery for operation. In a three-dimensional warehouse, the height of shelves is generally greater than that of a single-layer warehouse. The main technical parameters are as follows:

Height: the maximum height of the shelf can reach 40m;

Load: the maximum load of the shelf can reach 1500kg;

Running speed: the fastest running speed is 100m/ min;

Lifting speed: the maximum lifting speed can be 20m/ min;

Fork speed: the fastest fork speed is 1205m/ min;

Control mode: there are three main types of control modes for three-dimensional warehouses, namely, manual control, single machine automatic control and full-automatic control.

Classification of stereoscopic warehouse

As a matter of fact, there are many types of three-dimensional warehouses. Here, Hercules Hergels storage shelf manufacturer mainly introduces that if they are classified according to the types of goods loading machinery in three-dimensional warehouses, three-dimensional warehouses can be divided into two types, as follows:

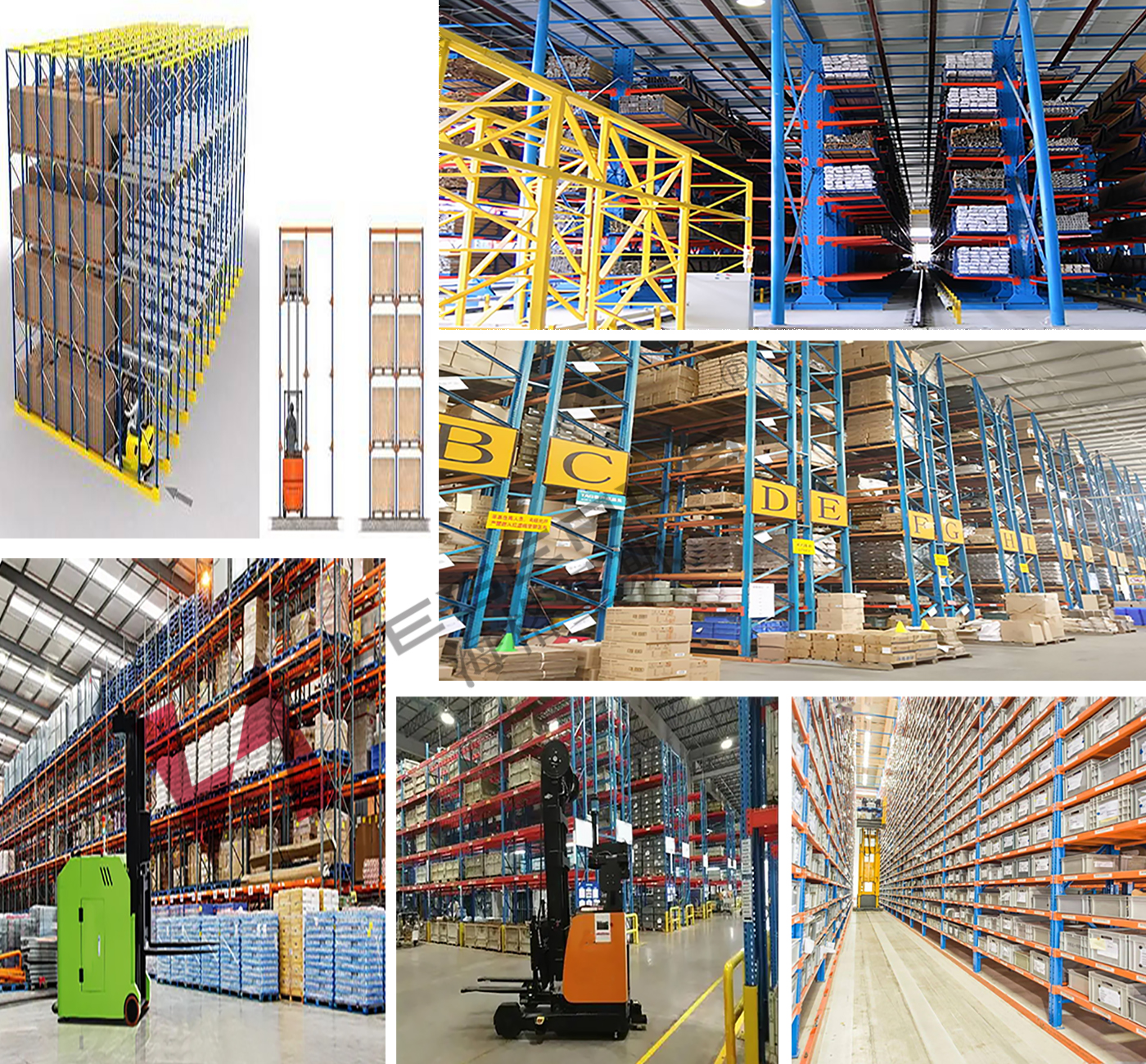

1) Rack forklift stereoscopic warehouse

There are three types of forklifts used in the three-dimensional warehouse, one is a high lift forklift, one is a forward moving forklift, and the other is a side forklift. The latter two forklifts also need a certain lifting height. The forklift is loaded by the ground, not a fixed facility, so it is more mobile. However, the passage width occupied by forklift operation is wide, and the large lifting height generally does not exceed 6m. Therefore, it is only applicable to medium and low-rise three-dimensional warehouses.

2) Three dimensional warehouse of roadway stacker

The aisle between shelves of the three-dimensional warehouse adopts the roadway stacker. The roadway stacker mainly adopts the drooping type of upper bearing and the lower bearing mode limited by the upper guide rail. It is mainly used for medium and high-rise three-dimensional warehouses.

Of course, with the rise of enterprises in different industries, the demand for materials from enterprises in different industries has increased, and both storage shelves and storage equipment have also increased and improved. Then there are major storage shelf manufacturers and suppliers. In recent years, with the development of the warehousing industry in Hebei, Hebei hegris hegerls storage shelf manufacturer has increasingly become a one-stop service provider required by major enterprises.

About hagerls storage rack forklift storage rack

Hagerls is the main brand of Hebei Walker metal products Co., Ltd. the company was founded in 1996, formerly known as Guangyuan shelf factory. It is an earlier company engaged in the shelf industry in North China. In 1998, it began to involve in the sales and installation of warehousing and logistics equipment. After more than 20 years of development, it has become a one-stop integrated service provider integrating warehousing and logistics project scheme design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc., with all-round, full series and full quality! Hagerls not only produces and manufactures storage shelves (shuttle shelves, beam shelves, three-dimensional warehouse shelves, fluent shelves, gravity shelves, steel platforms, drive in shelves, anti-corrosion shelves, etc.), but also produces and manufactures storage equipment (storage cages, stackers, elevators, intelligent conveying sorting lines, shuttle cars, four-way cars, pallets, bins, etc.). After entering the international market in 2011, it exported supermarket equipment, storage equipment and related supporting products to North America, South America, Europe, Southeast Asia, Africa and other countries and regions. Hercules Hergels storage shelf manufacturer has the right of self-supporting import and export. With many years of import and export experience, talents and import and export experience, the company has strong technical force, complete equipment, rigorous management technology and R & D and production experience. It is a high-quality enterprise among domestic peers and an enterprise with good reputation. In this regard, when it comes to forklift three-dimensional warehouse shelves, the Hercules Hegels storage shelf manufacturer also has its own opinions based on the feedback given by the major enterprises after their production, construction and use. The following is an overall introduction to the high location forklift three-dimensional warehouse shelves produced by the Hercules Hegels storage shelf manufacturer, Hope to be helpful to the major enterprises that want to put into use the shelves of high location forklift stereoscopic warehouse!

Description of shelves in hegerls high storage forklift stereoscopic warehouse

1. It is one of the widely used shelves, suitable for most warehouses or product goods.

2. Store with mechanical handling equipment.

3. Generally, the goods are stored on the shelf after being packaged by unit container equipment such as pallets and storage cages. The load of each unit is generally within 4000kg, and two units are usually placed on each floor.

4. The span of unit shelves is generally within 4m, the depth is within 1.5m, the shelves of low and high warehouses are generally within 12M, and the height of warehouse shelves is generally within 30m (such warehouses are basically automated warehouses, and the total height of shelves is composed of several sections of columns within 12m).

5. The height of each layer can be freely adjusted by an integral multiple of 75mm.

6. It has the characteristics of arbitrary picking of goods. Handling machinery such as forklift can reach any cargo location for storage, which is convenient and fast!

Shelf characteristics and performance advantages of hegris hegerls high location forklift stereoscopic warehouse:

1. The shelf height can be adjusted freely for the storage of various goods, and each layer can carry 800~5000kg, which can meet the storage requirements of different goods;

2. With strong bearing capacity and high stability, the cold rolled strip is processed by cold rolled steel as a whole. The cold rolled strip not only has the characteristics of low thickness and high precision, but also has a longer service life, strong bearing capacity and is not easy to deform due to the influence of its processing technology;

3. The three-dimensional structure can make full use of the warehouse space, improve the utilization rate of the warehouse capacity and expand the storage capacity of the warehouse;

4. Easy access to goods, can achieve first in first out, 100% selection ability, smooth inventory turnover;

5. Meet the storage and centralized management needs of large quantities of goods and a wide variety of goods. The goods on the shelves in the warehouse are clear at a glance and easy to count, divide and measure

6. Meet the management needs of modern enterprises' logistics supply chain with low cost, low loss and high efficiency.

The storage mode used in each warehouse will be different, and there will be great differences in space utilization, operation efficiency and enterprise input cost. In this regard, the Hergels storage shelf manufacturer suggests that major enterprises should pay attention to the following five matters in the selection of forklift trucks for three-dimensional warehouses:

1. Drive configuration of three-dimensional rack forklift

At present, forklifts on the market are generally driven by diesel or battery. The driving problem should be considered for indoor or outdoor operation. However, the difference between the two driving forklifts should also be considered comprehensively. Each of the two forklifts has its own advantages. The battery driven forklift has the advantages of environmental protection, less noise, small turning radius and low operation cost; Diesel forklift has the advantages of great power, high speed and high efficiency.

2. Tonnage configuration of three-dimensional rack forklift

This directly determines the storage of goods in the warehouse. The different tonnage of forklift determines the carrying condition of goods; Mainly: 1.5T, 1.8T, 2T, 2.5t, 3T; The selection of purchase configuration depends on the weight of goods to avoid the problems of insufficient tonnage and excessive waste of cost input;

3. Lifting height configuration of three-dimensional rack forklift

It is necessary to understand the maximum lifting height of the forklift, so as to determine the number of layers of the warehouse shelves. As well as knowing that forklifts can bear multiple loads at each height, most forklifts will reduce their weight with the increase of height;

4. Comprehensive consideration of other components of three-dimensional rack forklift

Including comparison of multiple suppliers with tires, engines and brands, exhaust pipes and other components. In terms of tyres, it is recommended to use solid tyres and forklifts with small turning radius, which can be durable; The choice of forklift brand and engine performance are interrelated. The performance of big brand forklift is better, but the investment cost is relatively high.

5. Special rack special forklift

Although most storage shelves can be used with various forklifts in the warehouse, some special shelf types still need to be used with special forklifts. The most typical one is that the special scissor fork lift truck is used for the double depth rack. The narrow lane rack forklift truck has a narrow operation channel and needs to be equipped with a special three-way forklift.

Managers need to comprehensively consider the warehouse area, storage capacity, cargo weight, characteristics, access mode and other conditions, and then select the shelf form that meets their own needs. Different forklifts are used according to different storage methods to improve the logistics management and operation efficiency. In addition, Hercules Hergels storage shelf manufacturer has been serving every customer with the pattern of customer first and quality as the purpose for many years. The high-tech R & D team meets various customization needs and has strong production strength. You are welcome to call to negotiate business. We will serve you wholeheartedly.

Post time: Jun-20-2022