In recent years, with the increase of market demand, the warehousing and logistics industry has stepped into the era of automated system integration. The storage mode with storage shelves as the main body has gradually developed into the storage mode of automated logistics systems. The core equipment has also changed from shelves to robots+shelves, forming a system integrated logistics storage system. As a storage system integrated with shelf+shuttle car+elevator+picking system+control software+warehouse management software, box type four-way shuttle car has become an important carrier (unit bin goods+four-way shuttle car) for lane changing operation and storage of goods, and has been widely used in various storage projects. The box four-way shuttle is mainly used to provide fast access service for "goods arrival (machine) man" picking, and is considered to be an important part of the future intelligent logistics system.

At the same time, the existing shuttle car needs a special elevator to change the floor. When changing the floor, the shuttle car needs to determine the route from the elevator. There are no storage products and other obstacles on the route. Next, after changing the floor, the shuttle car can change the lane. This requires the shuttle car to enter the corresponding channel again after coming out of the floor lifted by the elevator; In this way, it takes a long time to change layers and lanes, and the work efficiency is slow; In addition, in the actual use process, when there are several shuttle cars working at the same time on the storage shelf, waiting time is required for changing lanes, which further causes inconvenience for shuttle cars to change floors.

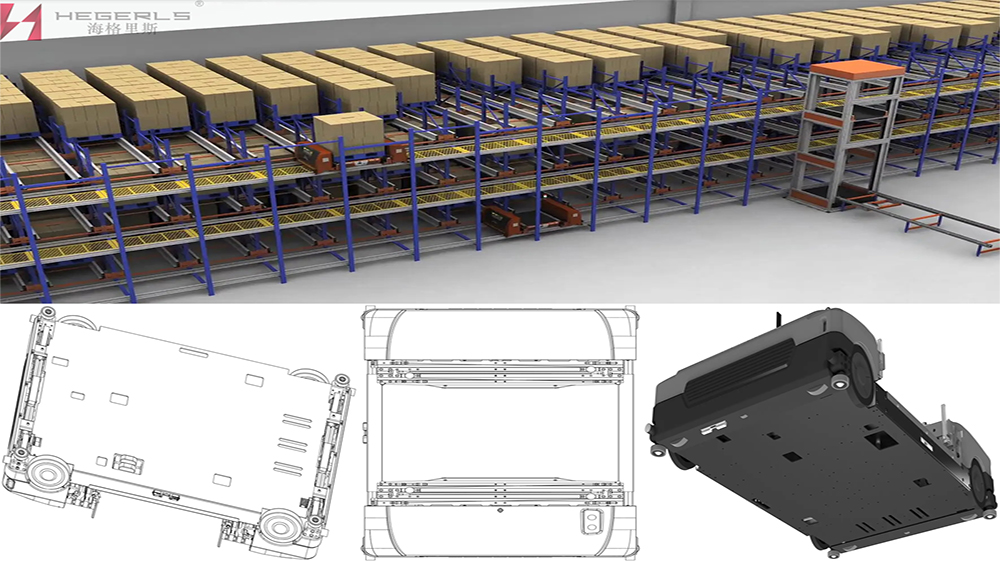

Recently, the core equipment and supporting system of the new generation of multi scene box four-way shuttle bus solution were independently developed by Hebei Walker Metal Products Co., Ltd. (self owned brand: HEGERLS), which marks that the multi scene flexible intelligent logistics solution has been innovated and optimized again, providing more options to further meet customer and market needs. The new generation multi scene box four-way shuttle solution of HEGERLS mainly consists of box four-way shuttle system, high-speed elevator system, box conveying system and picking operation system. The research and development of the box four-way shuttle makes up for the multi-dimensional defects of the current two-way shuttle movement. The operation lane can be changed at will, and the system capacity can be adjusted by increasing or decreasing the number of shuttle cars. If necessary, the peak value of the system can be adjusted by setting up the scheduling mode of the operation fleet, solving the bottleneck of warehouse entry and exit operations, and improving the work efficiency of warehousing and exit. Compared with the traditional automatic handling equipment, the box four-way shuttle can reduce the energy consumption and cost of handling by reducing the weight of the handling equipment. The four-way car drive part adopts efficient energy-saving motor, and uses the independently developed energy recovery technology to collect the released energy during the shuttle car deceleration process, reuse it, and reduce the shuttle car energy consumption.

HEGERLS box four-way shuttle

This is a kind of robot used for storage and retrieval of bins. Its corresponding technologies include Miniload and multi-layer shuttle car. Miniload is an AS/RS system dedicated to the storage and retrieval of bins. Compared with pallet AS/RS, Miniload is lighter and faster, but its height is generally not very high, and its load is generally less than 50kg; Multi layer shuttle is a reciprocating access device running in the shelf. Compared with Miniload, it is faster and more flexible. Therefore, when higher access speed is required, the multi layer shuttle has incomparable advantages of Miniload and is widely used in the goods to people picking system. The box type four-way shuttle car is a more flexible product. Similar to the pallet type four-way shuttle car, it has a wide range of adaptability. It can not only be applied to various warehouse types, but also can flexibly match the actual demand by increasing or decreasing the number of trolleys. Especially in the goods to people picking system, since the trolley can change layers through the elevator, in fact it can operate flexibly in 3D space, so it is more vividly called 3D Satellite Shuttle car abroad, which is incomparable to Miniload and multi-layer shuttle cars.

Working principle of HEGERLS box four-way shuttle

It is used for box type cargo handling. It can travel in four directions to realize cross roadway handling and loading and unloading of goods. It is suitable for box type stereo access working scene. The shuttle car system consists of a high-speed elevator and a shuttle car. After completing the operation in the roadway, the shuttle car enters the high-speed elevator, and the high-speed elevator carries the shuttle car to move up and down in the vertical direction, switch the operation layer, or return to the conveyor line layer for warehousing.

Performance characteristics of HEGERLS box four-way shuttle

Hoists: There are two typical structures, with car hoist and without car hoist. The car elevator is mainly used for the layer change of shuttle cars. Sometimes, in order to simplify the system, the car elevator can be used every time, but the operation efficiency will be greatly reduced. The lifting opportunity without car has a large lifting capacity. Sometimes, a double station elevator can be used, with the lifting capacity of 250~500 times per hour.

Speed and acceleration: in order to improve the working efficiency, the speed of the trolley will be as high as 5m/s. Because of the clamping device, the acceleration of the trolley can reach 2m/s2, which greatly improves the working efficiency of the trolley. For the hoist, the hoisting speed will generally reach 4~6m/s to match the efficiency of the whole system.

Load transfer: relatively speaking, the hopper shuttle is much more flexible. This is mainly because after the unit becomes smaller and lighter, there can be many ways to transfer the load. The simplest way is to use forks. In order to improve the storage density, double depth forks can be used. Sometimes, in order to adapt to cartons with different widths, forks can also be changed in width. The fork is actually the most important part of the shuttle.

Exploration on the application field of HEGERLS box four-way shuttle

The box type four-way shuttle is widely used. On the one hand, although it has something to do with its flexibility and flexibility, more importantly, the development of e-commerce has promoted the rapid development of sorting. The high efficiency of the four-way shuttle is one of the important reasons for its popularity. Its main applications are summarized as follows:

Goods collection and queuing: The box type four-way shuttle is also often used for goods collection and queuing in the delivery process. The material box can be directly connected with the telescopic belt conveyor, so that the loading can be completed more directly. In the case of multiple delivery destinations, the shuttle can also play the role of queuing to solve the previous problem of loading sequence.

"Goods to people" storage system: The earliest application of the four-way shuttle is its application in the goods to people picking system. Compared with the multi-layer shuttle, the four-way shuttle has not only high efficiency, but also high flexibility, which makes its application more extensive. However, with the continuous improvement of the requirements for inbound and outbound capacity, when the capacity of the trolley becomes the bottleneck, the price advantage of the multi-layer shuttle will be more obvious.

Others: The four-way shuttle car with material box is widely used. At present, the applications we have learned include various large-scale storage systems (especially those with large storage capacity and low warehousing frequency), such as libraries and archives. In addition, there are prospects for application in other logistics links, such as production line side warehouse, sorting system, etc.

The five highlights of HEGERLS box four-way shuttle system technology:

Energy saving: compared with traditional handling equipment, the box type four-way vehicle consumes less energy for single handling operation due to its light weight. At the same time, through the energy recovery technology of four-way vehicle, the energy in the deceleration process can be recovered to further reduce the system energy consumption;

Multiple warehouse layout options: the quick shuttle system can be arranged anywhere in the upper and lower floors of the factory building, which does not require a high height of the factory floor, and is also suitable for the storage area with irregular shape;

Flexible, modular and expandable: it can meet the handling operation of single vehicle at any position on the same floor through flexible lane changing function; Multiple machines can work together on the same layer, which can meet the peak inbound and outbound operation requirements during the actual use of the project, and the system can conduct lean configuration of equipment according to the actual business development needs of users;

Less occupied area: less tunnels are needed under the same processing capacity, reducing the use space and floor area;

Four way vehicle scheduling system: the task can be globally optimized according to the task state and the current running state of the four-way vehicle, to maximize the overall efficiency of the four-way vehicle system, and to meet the use needs of the storage system with the most economic input.

The HEGERLS box type four-way shuttle car is mainly suitable for 600 * 400 standard boxes, with a carrying capacity of 50kg. The future system mainly seeks serialization in terms of size and fork type to meet the market demand. At the same time, there is no doubt that the market potential of box four-way shuttle technology is very large.. The degree of market acceptance of a technology depends on the reliability and maturity of the technology itself. Successful cases of technology application are the primary conditions for market acceptance. At present, whether influenced by the "goods to people" delivery technology trend or catalyzed by intelligent manufacturing, the application scenario of the box four-way shuttle will continue to expand, with broad market prospects.

Post time: Nov-14-2022