With the improvement of people’s life and the demand for living goods, the current logistics distribution service can be said to be very convenient and fast. When we can enjoy the timely appearance of packages with our hands, don’t forget that there is a high-quality logistics distribution center behind such timely distribution. For users who need transportation services, there is a high-quality logistics distribution center, which can make the goods transported more safely and efficiently.

In order to build a high-quality logistics distribution center, we must first understand the process of the logistics distribution center, that is, the goods are warehoused first. The logistics distribution center performs a series of operations such as information entry, goods inspection and warehouse location allocation according to the goods warehoused, and allocates the goods warehoused; Then, sort and distribute goods. After warehousing, pick up and sort goods according to the distribution demand scheme, and make corresponding outbound processing; Then there is transportation and distribution, assigning transportation personnel and vehicles, loading goods with transportation mode, analyzing and selecting transportation route, and delivering goods to users in an efficient way.

We should know that logistics distribution center is an important link in complex supply chain management, which directly affects the efficiency and cost of logistics. So, how to build an efficient and high-quality logistics distribution center? Hebei hegris hegerls storage shelf provider is a diversified storage shelf Center Rising in recent years. With the needs of users, it has provided many intelligent storage intensive storage systems and solutions with different types and functions. At the same time, in recent years, it has made significant progress, upgraded, more intelligent, flexible and more systematic in terms of intensive storage systems and solutions. As for how to build an efficient and high-quality logistics distribution center, it has its own unique design, production, manufacturing, integration, installation, commissioning and after-sales service. It is a one-stop integrated service experience and experience of all-round, all series and all-quality warehousing and logistics. Now let’s take a look at how hegerls warehouse shelf manufacturer builds an efficient and high-quality logistics distribution center? The following indicators need to be analyzed and considered:

We should know that logistics distribution center is an important link in complex supply chain management, which directly affects the efficiency and cost of logistics. So, how to build an efficient and high-quality logistics distribution center? Hebei hegris hegerls storage shelf provider is a diversified storage shelf Center Rising in recent years. With the needs of users, it has provided many intelligent storage intensive storage systems and solutions with different types and functions. At the same time, in recent years, it has made significant progress, upgraded, more intelligent, flexible and more systematic in terms of intensive storage systems and solutions. As for how to build an efficient and high-quality logistics distribution center, it has its own unique design, production, manufacturing, integration, installation, commissioning and after-sales service. It is a one-stop integrated service experience and experience of all-round, all series and all-quality warehousing and logistics. Now let’s take a look at how hegerls warehouse shelf manufacturer builds an efficient and high-quality logistics distribution center? The following indicators need to be analyzed and considered:

2、 Building index

After the site selection is completed, the next step is to enter the design stage of the logistics center. At this time, the attention should be relatively narrow. Generally, the basic principles of from outside to inside and from shallow to deep are followed, including gate, road (generally, one-way lane is not less than 4.5m, two-way lane is not less than 7-8m, and busy system requires wider road), parking lot, platform and canopy, building area, column network Floors (for single storey buildings, if automatic three-dimensional warehouses are used, the recommended floor height is 24m; if heavy shelves are used, the height is preferably less than 15m; while for multi-storey buildings, if shelves or attics are used, the height of 6.7 ~ 7m is more appropriate), fire compartment, etc.

3、 Warehouse index

The construction of logistics distribution center needs to analyze the design objectives and influencing factors of warehouse. The design goal needs to have an in-depth analysis of the throughput of warehousing and outbound, and clearly define the user’s order quantity, their own storage quantity and storage turnover period. We should also have a clear understanding of the influencing factors, such as peak throughput and normal throughput, development forecast in the next 2-3 years, etc., determine the budget and project objectives, and adopt the corresponding sorting equipment, handling equipment, warehousing software system, etc.

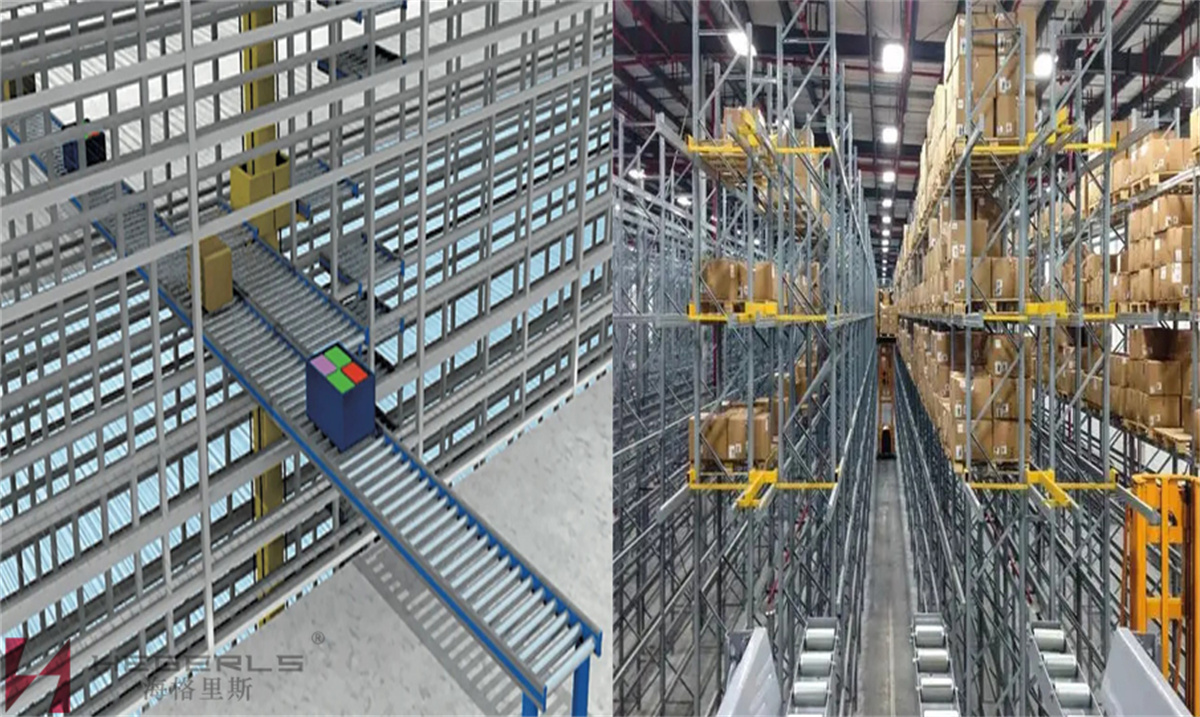

4、 Equipment index

Designing a rigorous and regular logistics system is not a simple job, but also a kind of meticulous work. Of course, the most important thing is the selection of equipment. In the process of selecting what kind of equipment, the most critical point still depends on the specific items of the logistics center and the storage efficiency to be achieved; Of course, the cost performance of equipment is also an important content we need to consider. However, no matter what industry’s logistics center, to meet the needs of inventory and throughput capacity can make the design and demand match.

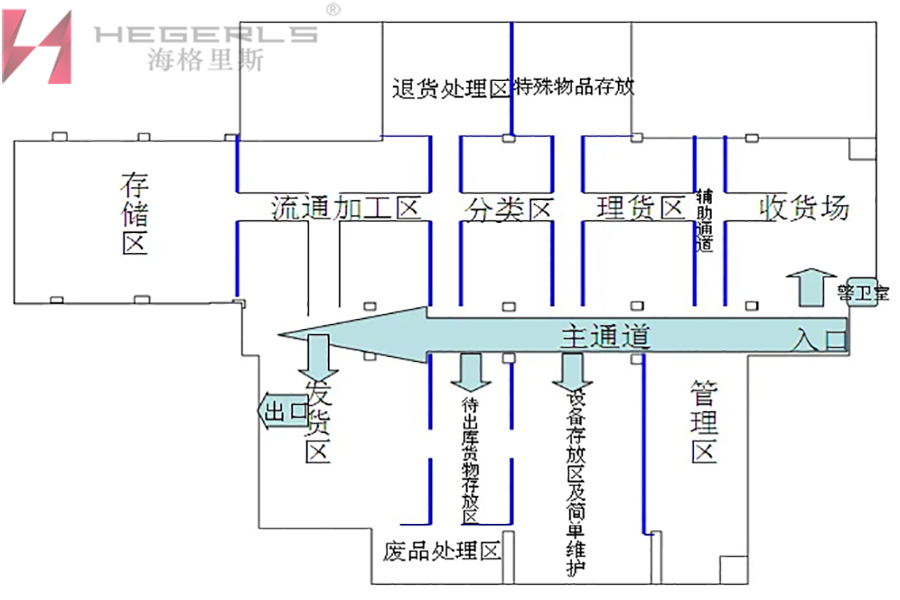

5、 Warehouse planning index

Generally speaking, the size and target plan of the warehouse basically determine the design of the warehouse, but in terms of the function of the warehouse, it is still necessary to make a detailed plan for each area. The receiving area and inventory area occupy most of the warehouse area. The planning of these functional areas should be in line with the warehousing and outbound, reasonably allocate the location planning, and analyze the time period and quantity of receiving goods and the number of trucks and staff that can be carried under normal circumstances. Secondly, there are sorting areas and management areas, which need to be planned according to the functional characteristics of these areas.

Of course, in addition to the five indicators produced in different stages of logistics center planning, there are also two key indicators running through the planning and development of logistics center, namely cost and efficiency. Talking about the optimization of logistics center without these two indicators is tantamount to abandoning the basics. In most cases, efficiency and cost restrict each other. Improving efficiency and reducing cost are the whole goal of logistics system design and operation. The cost mainly includes two parts: construction cost and operation cost. Fundamentally, the goal of logistics center design and research is how to control the cost on the premise of meeting the growing demand. Efficiency can also be divided into two parts: one is the operation ability per unit time, and the other is the basic embodiment of service level, which are also closely related to cost. People who know about the logistics center should know that the specific requirements of the logistics system are mainly reflected in 6R, that is, the right goods are delivered to the right customers at the right time, in the right quantity, in the right state and in the right direction. At the same time, this is not only the key evaluation index of the service of the logistics center, but also the fundamental purpose of the construction and operation of a logistics center.

Post time: May-27-2022