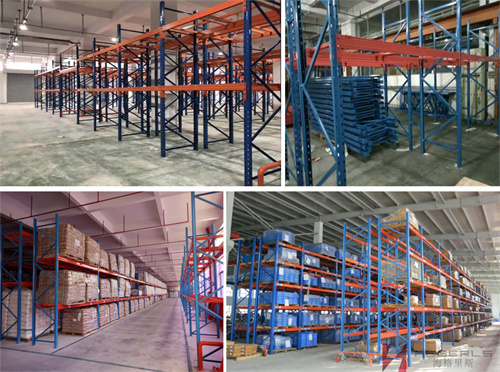

Shelf plays an important role in modern logistics. The standardization and modernization of warehouse management are directly related to the types and functions of shelves. Shelves can fully make the warehouse valuable, solve the clutter of the warehouse, and solve the problem of expensive rent due to insufficient warehouse space. The cross beam shelf is a kind of shelf widely used in warehouses in various industries. It has a large bearing capacity and can make full use of space. Equipped with various forklifts or stackers, it can realize rapid access to pallets or storage units.

About hagerls warehousing

In recent years, our company (hagerls warehousing) has undertaken many projects related to cross beam shelves in different industries and enterprises. Hagerls is also a storage shelf manufacturer that has emerged in Hebei in recent 20 years, focusing on planning, design, production, sales, installation and service. Headquartered in Shijiazhuang, Xingtai production base, Bangkok, Thailand, Kunshan, Jiangsu and Shenyang sales branches. It has a production and R & D base of 60000 square meters, 48 world advanced production lines, and more than 300 people in R & D, production, sales, installation and after-sales, including nearly 60 people with senior technician and senior engineer titles. The storage shelves and storage equipment produced by the company have been certified by SGS, BV and TUV international product quality inspection institutions, “quality, environment and health” ISO three system certification, etc. at the same time, they have won the titles and honors of “China’s quality service reputation AAAA brand enterprise”, “National product quality assurance standard enterprise”, “China’s famous brand product” and so on.

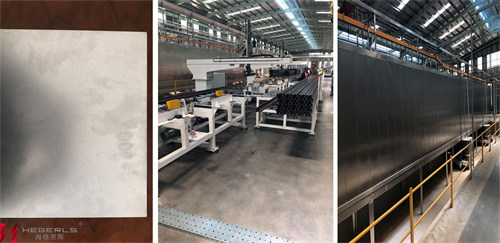

The company has a number of precision production equipment, qualified spraying lines and pretreatment spray systems, a number of fixed cold-formed profile automatic rolling production lines and multi-functional rolling production lines manufactured by mature technology, automatic continuous punching production lines of steel strips and a number of CO2 automatic welding production lines; Complete equipment and mature technology can solve problems related to warehousing and logistics for enterprises in different industries. In terms of quality management, we strictly follow the three ISO systems of “quality, environment and health”, constantly absorb the mature management technology of domestic and foreign warehousing and manufacturing enterprises, and constantly develop new technologies and launch new products in combination with the actual situation of domestic enterprises. According to the needs of different customers, our company can also customize various light, medium and heavy shelves and various storage peripheral equipment. At present, many storage shelves and storage equipment have been used in logistics, aviation, electronics, automotive, medical, military, power and other industries.

Our company pays attention to the connection between products and the market, and the product R & D team with special experience, while grasping the product quality, continues to develop new models suitable for the market demand. The development of high specifications and diversification enables our products to better integrate the various needs of modern warehouses, greatly improving the storage efficiency of warehouses, and achieving the purpose of greater utilization of storage value.

Heavy beam rack (selective racking)

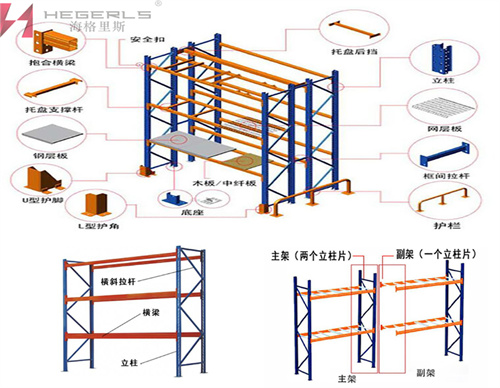

Beam type shelf is a warehouse shelf for the purpose of storing and storing pallet goods. Each pallet is a storage space, so it is also called storage space type shelf. The heavy-duty crossbeam rack is simple in structure, safe and reliable, and can be adjusted and combined at will, and it is not limited by the sequence of items in and out of the warehouse. The column piece of the cross beam shelf is connected by the column, cross brace and diagonal brace with bolts. The column piece and the C-shaped welding beam are inserted to form the shelf frame, which is fixed with safety pins, and the structure is simple and reliable. At the same time, each layer can be freely adjusted up and down in 75mm or 50mm steps; Among them, the height of a single column can reach 12 meters, and the plasticity of pallet shelves is very large. Mold shelves, attic shelves, three-dimensional warehouse shelves, etc. can also be built on the basis of pallet shelves, which can also be made into special oil barrel shelves. Not only that, the cross beam shelf can also be equipped with laminates, which can be steel plates, dense ammonia plates or grid nets, so as to cooperate with the use of trays of different sizes. The beam type shelf can determine the layer load requirements with the size of the column and beam. It has the characteristics of large moment of inertia, strong layer load capacity and strong impact resistance. The larger layer load of each layer can reach 5000kg/ layer under the relative design. The biggest feature of beam type shelf is that it can improve the storage height of the warehouse and improve the space utilization rate of the warehouse. It is widely used in the storage mode of pallet storage and forklift access. The crossbeam shelf is low-cost, easy to install and operate, easy to find the location, suitable for any handling tools, widely used in manufacturing, third-party logistics, distribution centers and other fields, and also suitable for the storage of various types of goods. Hagerls will provide crossbeam shelves of different specifications for selection according to the actual use conditions of users: pallet load requirements, pallet size, actual warehouse space, and actual lifting height of forklifts.

Beam shelf classification

For more than 20 years, hagerls storage has undertaken the automatic storage beam shelf project. According to the requirements of its customers, our company can not only produce customized heavy beam shelves, but also produce beam shelves, pallet beam shelves, narrow lane pallet beam shelves, heavy storage shelves, mobile beam shelves, withdrawable beam shelves, etc.

Working principle of cross beam shelf

Heavy shelf crossbeam shelf is common in various domestic storage shelf systems. First of all, it is necessary to carry out the unitization work, that is, the packaging of goods and their weight and other characteristics, and determine the type, specification, size, single support load weight and stacking height of the pallet (the weight of single support goods is generally within 2000kg), and then determine the span, depth and layer spacing of the unit shelf, and determine the height of the shelf according to the effective height of the lower edge of the warehouse roof truss and the fork height of the forklift truck. The span of unit shelves is generally within 4m, the depth is within 1.5m, the height of low and high-level warehouses is generally within 12M, and the height of super high-level warehouses is generally within 30m (such warehouses are basically automated warehouses, and the total height of shelves is composed of several sections of columns within 12m). In such warehouses, low and high-level warehouses mostly use forward moving battery forklifts, balance weight battery forklifts, and three-way forklifts for access operations. When the shelves are low, electric stackers can also be used, and super high-level warehouses use stackers for access operations. This kind of shelf system has high space utilization rate, flexible and convenient access, supplemented by computer management or control, and can basically meet the requirements of modern logistics system.

How to design the length, width, height, passage, etc. of the cross beam shelf?

Length design of cross beam shelf:

(1) Understand the specifications of the pallet.

(2) Generally, two pallets are designed to be placed on each floor, and the spacing between pallets is 70-100mm (the spacing between high shelves is 100mm, and the spacing between low shelves can be 70mm). If the pallet length is small (such as 800mm), three pallets can be placed on each layer.

(3) Formula: l= pallet length *2 (70-100) *3 (number of intervals)

Design of beam shelf width:

(1) It is calculated based on the actual size of the pallet width.

(2) If the customer requires to add span beams, lay steel plates, planks and other accessories, the shelf width can be designed to be the same size as the pallet width.

(3) Formula: d= pallet width 200mm.

Design of height of cross beam shelf:

(1) The specific height depends on the customer’s warehouse space and the factors of lifting height with forklift.

(2) The height should be an integral multiple of 75mm. If not, take a similar value.

(3) Formula: H (floor height) = cargo height 150 (interval) beam height (different load-bearing and specifications).

Passage: determine the passage of forklift according to the performance of forklift (such as operation passage, lifting, load, etc.).

Hegerls crossbeam shelf is different from other heavy shelves

The biggest difference between the crossbeam shelves produced by Hergels storage manufacturer and other storage shelf manufacturers is that they have high corrosion resistance. The application of special steel added with Al, Mg, Ni, Cr and other alloys in anti-corrosion products of Hagrid’s anti-corrosion shelves can be traced back to the beginning of the 21st century, and the main purpose is to further improve the corrosion resistance of steel plates. The surface treatment of anti-corrosion shelves plays an important role in the whole production process. The strict control of pre-processing, equipment debugging in processing, post-processing, surface passivation and coating methods can ensure the anti-corrosion performance of shelf products. During the later installation of shelf products, the use of some shelf accessories also ensures the anti-corrosion performance of the products to a certain extent. This kind of anti-corrosion shelf material has better corrosion resistance. The increase of Al, Mg, Ni and Cr content within a certain range makes the corrosion resistance of steel plate several times to more than ten times higher than that of ordinary plate. Due to the anti-corrosion treatment of pre machining, intermediate and post machining processes, the raw materials are always isolated. Finally, the selection of anti-corrosion coatings and the treatment of special processes ensure that the anti-corrosion performance of materials is significantly better than that of traditional products. At the same time, the application of anti-corrosion shelves in the hazardous waste treatment industry has greatly reduced the input cost of fixed assets of hazardous waste enterprises, and also reduced the management and time costs brought to enterprises by replacing shelves.

The use of anti-corrosion raw materials has laid a solid foundation for the corrosion resistance of the shelf, but only the first step has been completed for the formation of anti-corrosion shelf. The anti-corrosion measures in the product machining process are also very important. Our anti-corrosion products strictly control the protection of the substrate during the processing, so that the substrate remains isolated from external substances. After processing, the pretreatment process of the product can not only ensure the cleanness of the substrate surface, but also form a dense protective film on the substrate surface. This protective film can isolate external pollutants before coating and help the coating absorb. Aiming at the problem of coating sealing, our products adopt the secondary coating process of high corrosion resistance coating, which greatly improves the sealing of the coating. The anti-corrosion accessories used in the installation process and the daily operation and maintenance after use ensure the corrosion resistance of the product. Our company has also jointly carried out the demonstration design of dip galvanizing after replacing Q235 and Q345 with anti-corrosion materials, and the demonstration design of anti-corrosion treatment and coating selection in the processing process with hazardous waste treatment enterprises, which meets the needs of high corrosion resistance and standardized management in the hazardous waste treatment industry.

Set up a special customer manager team for customer hegerls, including sales, R & D, installation and commissioning, and operation and maintenance service team. For quality control, production scheduling and product shipment, hegerls arranges special personnel to follow up. Hegerls customer service team visits customers at least once a year to timely understand the use of products and users’ demands in terms of delivery, quality, operation and maintenance. If users find problems or raise objections during the use of the product, hegerls will promise to arrive at the customer’s site within 24 hours and form a treatment plan within 48 hours.

Post time: Jul-25-2022