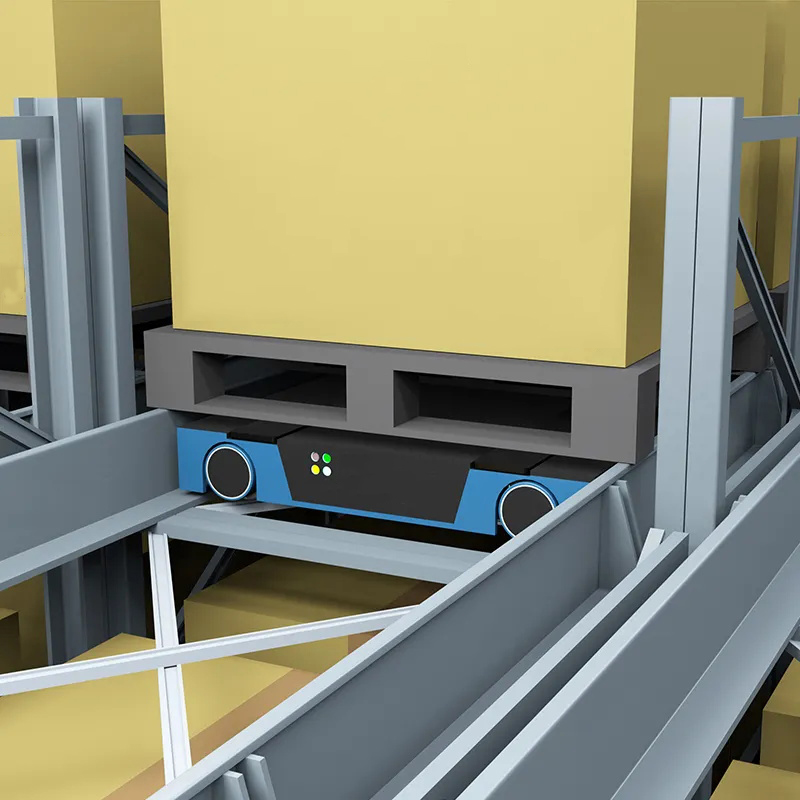

As an important handling equipment for intensive storage, the four-way shuttle is an automatic cargo handling equipment. Its system is composed of four-way shuttle, fast elevator, horizontal conveying system, shelf system and WMS/WCS management and control system. It is connected with wireless remote control, combined with RFID, barcode and other identification technologies, to easily realize automatic identification and storage of shelf goods. The principle of four-way shuttle car inventory is to place the four-way shuttle car on the running rack track under the pallet. Under the guidance of the remote control command or the wms system, face up the shuttle car’s lifting platform, lift the pallet unit and run it to the destination, and then store the goods on the pallet to the cargo space. The four-way shuttle truck can also be equipped with a forklift or a stacker, that is, a forklift or a stacker can place the pallet unit goods in front of the lane guide rail of the four-way shuttle truck rack, and then the warehouse workers can operate the four-way shuttle truck with radio remote control to carry the pallet unit to run on the rack guide rail and place it on different rack rails. A four-way shuttle truck can be used for multiple rack lanes and transported to the corresponding cargo space. The number of four-way shuttle cars is determined by the comprehensive factors such as the roadway depth of the shelf, the total freight volume and the frequency of inbound and outbound.

About HEGERLS

HEGERLS is specialized in integrating intelligent intensive warehouse, automated stereoscopic warehouse, cold storage automated intelligent warehouse, warehouse rack integration (warehouse rack integration), intelligent cold storage, four-way shuttle car, parent and child shuttle, shuttle board, stacker, conveyor line, sorting line, steel structure attic platform, attic shelf, automated warehouse shelf, high shelf, various types of storage shelves, system integration, soft control Intelligent factory manufacturer and supplier integrating electric control. It has a production and research and development base of 60000 m2, 48 world advanced production lines, more than 300 people in R&D, production, sales, installation and after-sales service, including nearly 60 people with senior technicians and senior engineers. HGRIS always attaches importance to product innovation and R&D, and has excellent equipment. It has many automatic cold bending production lines for high-precision profiles, various types of processing equipment, full-automatic suspension spraying lines and pre-treatment cleaning shot blasting systems, which can provide epoxy resin, polyester resin or metal powder, anti-static spraying, and automatic welding. The main products of Highrise include:

Intelligent warehouse product series: automated warehouse, cold chain automated warehouse, shuttle car warehouse, stacker stacker warehouse, warehouse rack integration, vertical warehouse shelves, four-way shuttle car, parent shuttle car, stacker, elevator, lifting transfer machine, AGV, intelligent sorting and conveying system, WMS warehouse management system, WCS warehouse control system, etc.

Storage shelf series: stereoscopic warehouse shelf, heavy shelf, medium shelf, beam shelf, cold storage shelf, shuttle shelf, through shelf, narrow channel shelf, double depth shelf, mold shelf, 4S store shelf, gravity shelf, press in shelf, attic shelf, attic platform, steel structure platform, etc.

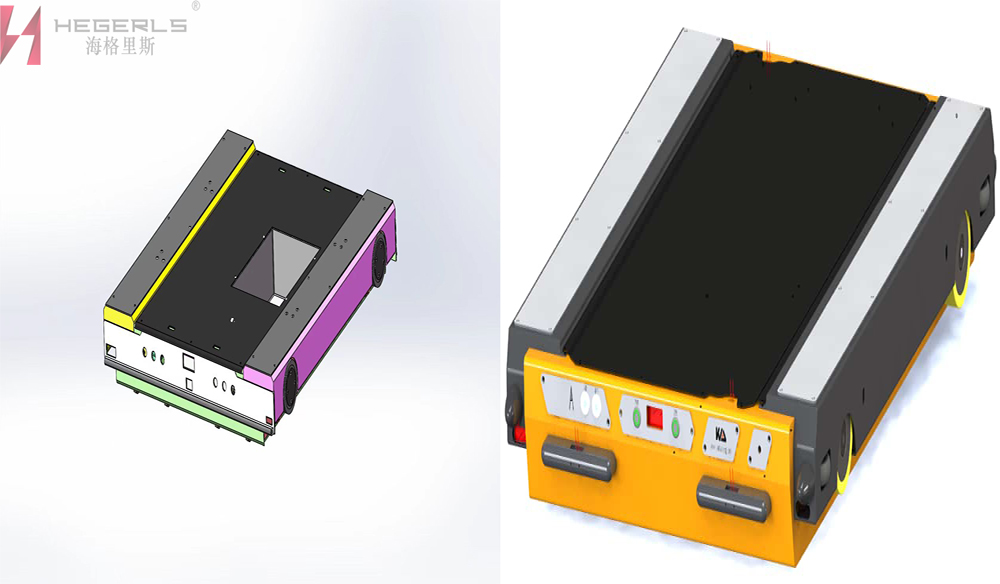

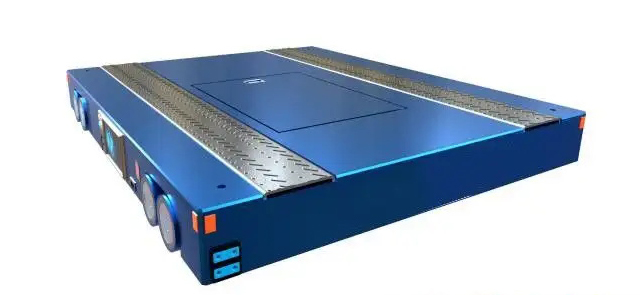

Higelis four-way shuttle

The four-way shuttle is an intelligent four-way transport robot with high space utilization and flexible configuration. It can not only improve work efficiency, but also save unnecessary labor costs for enterprises more effectively, and is widely used in various industries. The four-way shuttle car adopts a pure mechanical structure, with a long service life cycle. At the same time, it adopts a mechanical jacking design, without the risk of aging of the hydraulic structure seal ring, without the need to change the hydraulic oil frequently, with low maintenance costs and more energy efficiency. The four-way shuttle car can be compatible with the two-way shuttle board shelf, reducing the cost of upgrading the intelligent warehouse; At the same time, its automatic dust removal system can adapt to more complex environments. The four-way shuttle solves the problem that the traditional shuttle cannot move laterally, which is also a good feature of the four-way shuttle. The four-way shuttle has the ability to move in four directions, which also determines that the four-way shuttle has a wider application range and greater flexibility, and the system has higher security and stability. For example, when a car has a problem, the four-way shuttle can change the roadway at will, increase or decrease the number of shuttle cars to adjust without affecting the overall warehousing and unloading capacity of the system. The four-way shuttle truck does not need a forklift to enter the interior of the shelf, so it is efficient to import and export goods.

Why do more and more warehouses choose to use the HGIS four-way shuttle?

Floor area ratio: In warehouses with the same area, the floor area ratio of ordinary shelves is 34%, and that of four-way shuttle racks is up to 75%. The floor area ratio of four-way shuttle racks is twice that of ordinary shelves.

Access mode: The common storage rack can only meet the single access mode of first in first out or first in last out, while the four-way shuttle truck rack can achieve two access modes. Therefore, the four-way shuttle rack is more suitable for food, medical and other industries requiring higher access modes.

Storage efficiency: compared with ordinary storage shelves, the four-way shuttle truck rack forklift does not need to enter the goods into the shelves. One worker can operate multiple shuttle trucks at the same time, greatly reducing the waiting time for operation and greatly improving the work efficiency.

Safety: The rack structure of four-way shuttle is very stable. In addition, the shuttle truck accesses goods inside the shelf, and the forklift only needs to operate outside, avoiding the collision between the forklift and the shelf, and ensuring the safety of personnel and equipment.

Is there any requirement for the guide rail of the storage rack when using the four-way shuttle?

The four-way shuttle truck rack is a popular automated intensive storage rack system in recent years. Many enterprise customers have begun to upgrade the traditional racks in their warehouses to four-way shuttle truck racks. The four-way shuttle truck rack is a new type of automated storage rack system, which is divided into bin type and pallet type according to different goods. As a popular intelligent intensive storage system in recent years, the four-way shuttle rack has been applied in medical, food and other fields. Different from the traditional storage racks, a forklift operation channel needs to be reserved between them. The four-way shuttle truck racks use the four-way shuttle truck to access and transport goods. The aisle where the four-way shuttle truck runs is the pallet space for accessing goods, which makes the four-way shuttle truck rack design more compact and saves more storage space in the warehouse.

Post time: Oct-22-2022