In the automatic logistics transportation system, the shuttle vehicle (RGV) is an important transportation equipment. Its structure is simple, flexible, and can realize any change of the transportation destination. It can replace a large number of ordinary transportation equipment, simplify the process, and reduce the floor area. Therefore, it has been widely used in the logistics system. At the same time, in the diversification of shuttle cars (RGV), four-way shuttle cars are used in automated warehouse, and they are more and more widely used in horizontal and vertical tracks because of their high flexibility. The four-way shuttle can move across lanes and floors. Each four-way shuttle can reach any slot of the shelves in the warehouse. Therefore, when a four-way shuttle fails, it will not have too much impact on the overall operation of the warehouse. At the same time, because the number of equipment is no longer limited by lanes and floors, the WMS system WCS system of the warehouse can flexibly increase or decrease the number of four-way shuttle according to the system throughput requirements.

Hebei Walker Metal Products Co., Ltd. specializes in creating high-quality products

Hebei Walker Metal Products Co., Ltd., formerly known as Guangyuan Shelf Factory, was an earlier company engaged in the shelf industry in North China. In 1998, it began to participate in the sales and installation of warehousing and logistics equipment. After more than 20 years of development, it has become a one-stop integrated service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

It also established its own brand “HEGERLS”, established production bases in Shijiazhuang and Xingtai, and sales branches in Bangkok, Thailand, Kunshan, Jiangsu and Shenyang. It has a production and research and development base of 60000 m2, 48 world advanced production lines, more than 300 people in R&D, production, sales, installation and after-sales service, including nearly 60 people with senior technicians and senior engineers. The products and services of HGRIS cover nearly 30 provinces, cities and autonomous regions in China. The products are exported to Europe, America, the Middle East, Latin America, Southeast Asia and other countries and regions, and have made remarkable achievements overseas.

Products of HEGERLS:

Storage shelf: shuttle shelf, cross beam shelf, four-way shuttle car shelf, pallet four-way shuttle car shelf, medium shelf, light shelf, pallet shelf, rotary shelf, through shelf, stereoscopic warehouse shelf, attic shelf, floor shelf, cantilever shelf, mobile shelf, fluent shelf, drive in shelf, gravity shelf, high storage shelf, press in shelf, pick out shelf Narrow aisle type shelf, heavy pallet shelf, shelf type shelf, drawer type shelf, bracket type shelf, multi-layer attic type shelf, stacking type shelf, three-dimensional high level shelf, universal angle steel shelf, corridor type shelf, mold shelf, dense cabinet, steel platform, anti-corrosion shelf, etc.

Storage equipment: steel structure platform, steel pallet, steel material box, smart fixed frame, storage cage, isolation net, elevator, hydraulic pressure, shuttle car, two-way shuttle car, parent shuttle car, four-way shuttle car, stacker, screen partition, climbing car, intelligent transportation and sorting equipment, pallet, electric forklift, container, turnover box, AGV, etc.

New intelligent robot series: Kubao robot series, which includes: carton picking robot HEGERLS A42N, lifting picking robot HEGERLS A3, double depth bin robot HEGERLS A42D, telescopic lifting bin robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42 SLAM, multi-layer bin robot HEGERLS A42, dynamic width adjusting bin robot HEGERLS A42-FW, intelligent management platform, workstation Smart Charge Point.

Automated stereoscopic warehouse: shuttle stereoscopic warehouse, beam stereoscopic warehouse, pallet stereoscopic warehouse, heavy shelf stereoscopic warehouse, automated warehouse stereoscopic warehouse, attic stereoscopic warehouse, layer stereoscopic warehouse, four-way shuttle car stereoscopic warehouse, mobile stereoscopic warehouse, narrow roadway stereoscopic warehouse, unit stereoscopic warehouse, through stereoscopic warehouse, cargo format stereoscopic warehouse, automated cabinet stereoscopic warehouse, strip shelf stereoscopic warehouse, picking stereoscopic warehouse, semi-automatic stereoscopic warehouse Linear guideway stereo warehouse, U-guideway stereo warehouse, traverse guideway stereo warehouse, low floor stereo warehouse, middle floor stereo warehouse, high floor stereo warehouse, integrated stereo warehouse, layered stereo warehouse, stacker stereo warehouse, circulating shelf stereo warehouse, etc.

Warehouse management system: order management system (OMS), warehouse management system (WMS), warehouse control system (WCS) and transportation management system (TMS). The warehouse management system provided by HEGERLS can promote the efficiency improvement and cost reduction of the whole chain, and realize the real “intelligent warehouse configuration integration”.

About HEGERLS four-way shuttle system

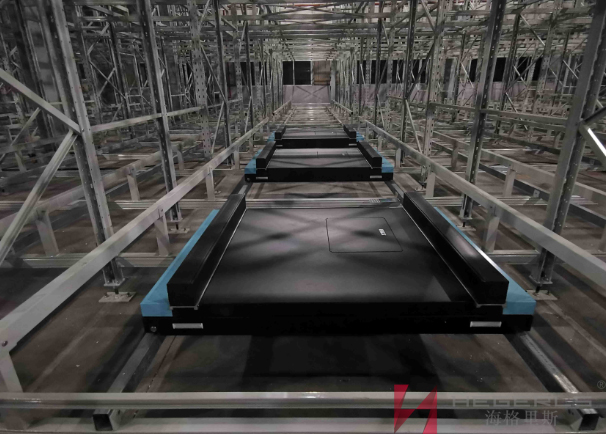

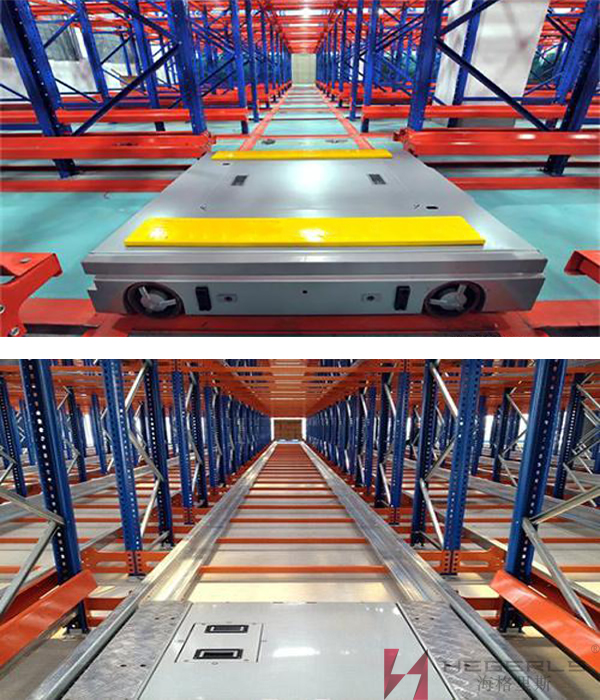

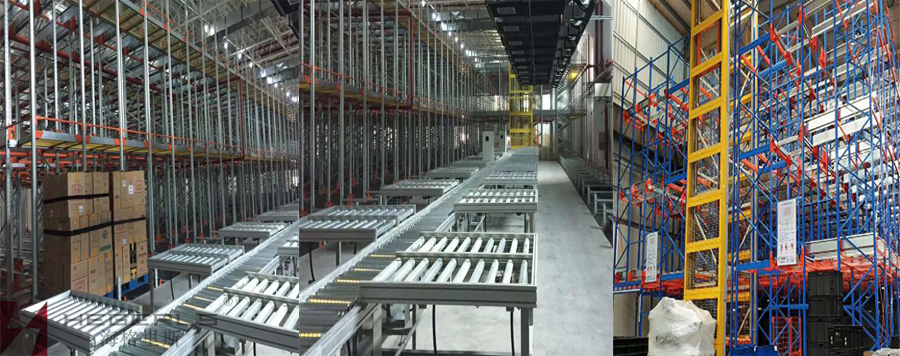

The four-way shuttle car rack system is divided into two parts: the four-way shuttle car and the corresponding rack system. In addition, the wireless network and WMS system, which are used to connect and control the whole system, cooperate with the elevator, etc., so that the goods can be freely transported to almost any shelf location, realizing all aspects of storage, picking and sorting. Compared with the traditional three-dimensional warehouse, this is more complex and systematic equipment. The four-way shuttle is an intelligent handling equipment, which integrates four-way change, automatic handling, intelligent monitoring, etc. Move pallet cargo longitudinally and transversely on the three-dimensional crossing track. When encountering obstacles or going to the end, it will automatically stop and make corresponding response, and choose a better walking route. The security and stability of the four-way shuttle truck rack system are higher. For example, in the traditional multi-layer shuttle system, if the hoist fails, the entire roadway operation will be affected; The four-way shuttle system can continue to complete the operation through the hoist, connecting equipment, etc., so that the system capacity is almost not affected. The four-way shuttle is generally suitable for food, beverage, medical, fine chemical and other products, and is suitable for low-temperature cold chain logistics.

Scope of application and advantages of HEGERLS four-way shuttle system

The HEGERLS four-way shuttle system has very high flexibility, which can flexibly change the working roadway, and adjust the system capacity according to the flexible increase or decrease of the number of shuttle cars. In addition, all four-way shuttles are based on modular and standardized design. When one of them fails, other vehicles can complete the operation. The HEGERLS four-way shuttle car can be used in irregular warehouses with large length width ratio, or warehouses with large warehousing efficiency and small warehousing efficiency. It has high flexibility and is suitable for high-density shelves. It can realize random shuttle. It can be flexibly adjusted according to the investment plans of different enterprises. In combination with a dedicated layer changing elevator, it can realize the layer changing of goods. In this regard, the HEGERLS four-way shuttle system highly reflects the characteristics of good ductility and adaptability, flexible picking, rapid deployment, safety and reliability, high-density storage, etc. The four-way shuttle can travel in multiple directions without space restrictions. It can transport goods across roadways and layers, and its operation mode is flexible and efficient. The box four-way shuttle can carry dozens of kilograms of box goods. It is basically similar to the tray four-way shuttle in structure and control mode, mainly different in design details and application scenarios. Of course, the charging mode of four-way vehicle is also automatic. It judges by itself that when the power is insufficient, it will automatically go to the charging area for charging, without manual check of power. It can also be automatically charged at idle time through program control to ensure the efficiency of warehouse automation.

Why do more and more enterprise warehouses choose the HEGERLS four-way shuttle?

Plot ratio

In warehouses with the same area, the proportion of common shelves is 34%, the proportion of four-way shuttle racks is up to 75%, and the proportion of four-way shuttle racks is twice that of common shelves.

Access mode

The common storage shelf can only meet the single access mode of first in first out or first in last out, while the four-way shuttle truck shelf can achieve two access modes. Therefore, the four-way shuttle rack is more suitable for food, medical and other industries requiring higher access methods.

Storage efficiency

Compared with ordinary storage racks, the four-way shuttle truck rack forklift does not need to enter the goods in the rack. One worker can operate multiple shuttle trucks at the same time, which greatly reduces the waiting time and improves the work efficiency.

Security

The rack structure of four-way shuttle is very stable. In addition, the shuttle truck accesses goods inside the shelf, and the forklift only needs to operate outside, avoiding the collision between the forklift and the shelf, and ensuring the safety of personnel and equipment.

HEGERLS has a fully automatic logistics robot as the key vehicle of the contemporary intelligent warehouse management system, which can carry out all kinds of transportation work 24 hours without interruption, which greatly reduces the amount of labor and security risks. As a result, HEGERLS can help small and medium-sized enterprises to establish a new modern intelligent warehousing management system, so that large enterprises can complete the operation of intelligent systems in all stages of warehousing, warehousing logistics, packaging, and express sorting, complete the whole process tracking and visual management of materials, and more reasonable use of warehousing space.

Post time: Dec-20-2022