With the rapid development of enterprise scale, many enterprises have increased the variety of goods and complicated business. The traditional extensive warehouse management mode is difficult to achieve accurate management. Coupled with the rising cost of labor and land, the automation and intelligence of warehousing also appear. In recent years, a variety of robots and solutions have been gradually introduced in the market, among which shuttle car stereoscopic warehouse and stacker stereoscopic warehouse, as the mainstream storage mode of pallet automated stereoscopic warehouse, have also attracted more and more attention and application. So what are the differences between the two warehousing modes? How should enterprises choose the appropriate storage type? Hebei hegris hegerls storage shelf manufacturer has simply sorted out and shared the applicable scenarios and storage characteristics of shuttle cars and stackers!

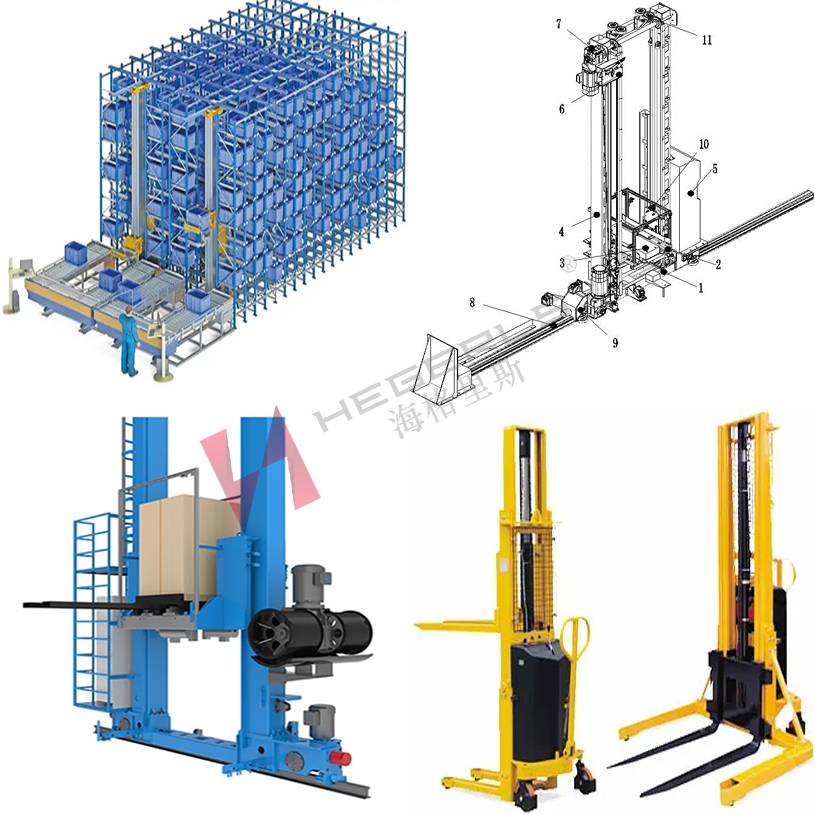

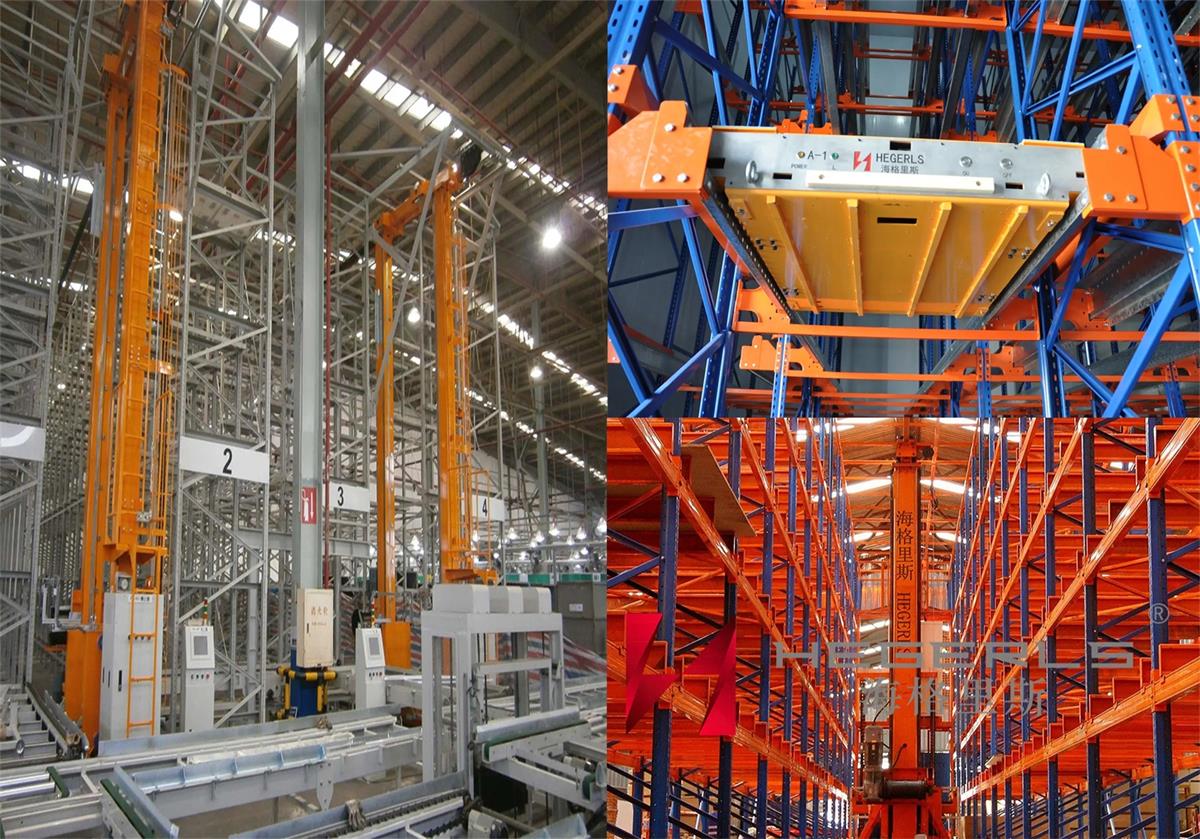

Stacker

The main function of the stacker is to run back and forth in the lane of the three-dimensional warehouse, store the goods at the lane crossing into the goods grid of the shelf, or take out the goods in the goods grid and transport them to the lane crossing. Through the cooperation of mechanical structure, the carriage can move freely in the three coordinate direction in the tunnel.

Unique advantages of stacker:

1) Improve storage utilization

The stacker is small in size and can run in the roadway with small width. It is suitable for shelf operation with different floor heights and improves the utilization rate of the warehouse;

2) High operation efficiency

Stacker is a special equipment for three-dimensional storage. It has high handling speed and goods storage speed, and can complete the warehousing operation in a short time;

3) Efficient stability

Stacking machines and tools have high reliability and good stability when working;

4) High degree of automation

In the modern intelligent warehousing system, the stacker can be remotely controlled. The vast majority of stackers are controlled by automatic control devices. This is also because the stacker is equipped with supporting facilities such as RFID reading and writing system, bar code induction system and radio frequency technology. Through the RFID reading and writing system, the bar code induction system accurately locates the material information and other contents in each warehouse location, and then cooperates with the dispatching command of the warehouse management system (WMS), Carry out accurate and efficient transfer of materials, so that the overall operation process can be unmanned and convenient for storage management.

RGV shuttle

The shuttle car is an intelligent transportation equipment, which can be programmed to realize the tasks of picking up, transporting and placing, and can communicate with the warehouse management system (WMS) to realize the automatic operation process by combining RFID, bar code and other identification technologies.

The shuttle car equipment can realize automatic cargo storage and retrieval, automatic lane change and layer change, and automatic climbing. It can also be transported and driven on the ground. It is the latest generation of intelligent handling equipment integrating automatic stacking, automatic handling, unmanned guidance and other functions. It has high flexibility. It can change the working roadway at will, and adjust the system capacity by increasing or decreasing the number of shuttle cars. If necessary, it can adjust the peak value of the system and solve the bottleneck of entry and exit operations by establishing the scheduling mode of working fleet.

The application scenarios and storage characteristics of RGV shuttle and stacker are compared as follows:

1) Application shelf

Shuttle cars are generally used for automatic dense high-rise shelves; The stacker shall be used for automatic narrow channel high-rise shelves.

2) Applicable scenarios

Shuttle cars are generally applicable to warehouses below 20m, and can be applied to multi column and irregular warehouses; The stacker is suitable for higher and longer warehouses and requires a regular layout.

3) Load

The general rated load of shuttle is less than 2.0T; The load of the stacker is higher. Generally, the rated load is 1T-3T, up to 8t or higher.

4) Operational efficiency

The shuttle car belongs to multi equipment combined transport operation, and the overall operation efficiency of the warehouse is more than 30% higher than that of the stacker; The stacker is different. It belongs to the single machine operation mode, and its efficiency limits the overall efficiency of warehousing.

5) Storage density

The stacker adopts single deep position and double deep position design, and the volume ratio of goods can generally reach 30%~40%; The shuttle car can design the depth according to the type of materials, and the plot ratio can generally be as high as 40%~60%.

6) Flexibility

In fact, the shuttle car body can travel in four directions, and can also reach any cargo location of the warehouse location. It has strong flexibility. Each car can support each other, so as to achieve the optimal configuration; For the stacker, each stacker can only run on a fixed track.

7) Late scalability

In the construction of the three-dimensional warehouse, the number of shuttle cars can be increased according to the later demand; However, the stacker cannot be changed or increased or decreased after the overall layout of the warehouse is formed.

8) Cost comparison

Generally speaking, the average cost of a single storage space for shuttle cars is 30% lower than that for stackers; However, the construction cost of the vertical warehouse of the stacker is high, the quantity of the warehouse location is small, and the average cost of a single cargo location is high.

9) Anti risk

Shuttle cars, all positions of single machine failure will not be affected. Other cars can be used to push the failed cars out of the roadway, and shuttle cars of other layers can be transferred to the failed layer to continue the task; Stacker, single machine failure, the whole roadway stops.

10) Operating noise

The shuttle car is powered by lithium battery. Its weight is relatively light and its operation is relatively quiet and stable; The self weight of the stacker is large, generally 4-5t, and the noise during operation is relatively large.

11) Energy consumption level

Shuttle cars are charged by using a charging pile. Each shuttle car uses a charging pile with a charging power of 1.3KW, which will consume 0.065kw for one time in and out of the warehouse; For the stacker, the sliding contact line is used for power supply. Each stacker uses 3 motors, and the charging power is 30kW. The stacker consumes 0.6kw to complete one-time out / in storage.

12) Safety protection

The stacker has a fixed track and the power supply is the sliding contact line. Generally, it will not easily cause safety failure; However, the shuttle car runs smoothly during work, and its body adopts a variety of safety measures, such as fire protection design, smoke and temperature alarm design, which generally will not easily cause safety failures.

In fact, from the perspective of comparison, it is not difficult for us to see that, as a traditional intelligent storage mode, the stacker has entered the market industry earlier and has more mature experience. However, with the continuous development and innovation of technology, with the advantages of flexibility, efficiency, density, intelligence, energy saving and so on, the hegris hegerls shuttle is gradually becoming a mainstream. If the storage efficiency of the warehouse is required to be high, and the goods need to be moved in and out quickly, the advantages of the stacker are more obvious. However, if the cost needs to be controlled or the length of each channel is short, it is more suitable to choose shuttle cars. However, in the actual warehouse construction and renovation project, the Hercules hegerls storage shelf manufacturer should also remind that it is necessary to integrate various factors to select appropriate storage solutions according to local conditions.

Post time: Jun-06-2022